Dusty Dan

New member

Equipment

BX2200, Dirt Master Backhoe, Essick VR30RE Road Vibratory Road Roller

BX2200 but maybe generic.

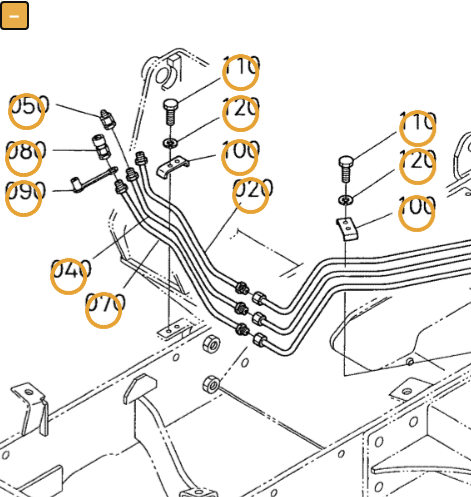

Quick question. Parts diagram shows the hydraulic line clamps, #100 below, "CLAMP, TUBE 75538-68610", bolting directly down on the steel hydraulic lines. Is this really the way it should be done? My lines are smashed in on top directly under the clamps. Purchased the tractor with 1000 hours on it so I don't have a history on this. About to install new factory lines.

Quick question. Parts diagram shows the hydraulic line clamps, #100 below, "CLAMP, TUBE 75538-68610", bolting directly down on the steel hydraulic lines. Is this really the way it should be done? My lines are smashed in on top directly under the clamps. Purchased the tractor with 1000 hours on it so I don't have a history on this. About to install new factory lines.

Last edited: