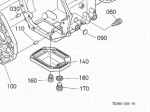

When I got this used tractor, the HST was slowly dripping. I have tried to address the drip to stop it but have only made a little progress. The threads in the transmission case are in bad shape. I've searched

on this forum to read solutions that different people have tried.

I've considered...and am still considering...a helicoil but have concerns. It seems that it would be easy...as well as common...to bungle the job. I got a new bolt and when it threads in, it does begin to grab but then just runs out of thread, it seems.

I got a new bolt and when it threads in, it does begin to grab but then just runs out of thread, it seems.

There are lots of opinions for solutions. I do not want to cause more issues by new tapping, etc. What are some solutions to try that would not entail re-tapping? Would rubber 0-ring be a possibility? I made a leather gasket hoping it would form to the hole and it did help some but there is still dripping. I've asked the Kubota dealer for the specs on this drain plug so that I can get right sizing...nothing was available in the WSM or online that I could find.

Thanks for any help!

Tractor Gal

on this forum to read solutions that different people have tried.

I've considered...and am still considering...a helicoil but have concerns. It seems that it would be easy...as well as common...to bungle the job.

There are lots of opinions for solutions. I do not want to cause more issues by new tapping, etc. What are some solutions to try that would not entail re-tapping? Would rubber 0-ring be a possibility? I made a leather gasket hoping it would form to the hole and it did help some but there is still dripping. I've asked the Kubota dealer for the specs on this drain plug so that I can get right sizing...nothing was available in the WSM or online that I could find.

Thanks for any help!

Tractor Gal