Adding water is cheapest but dont forget the antifreeze. My dealer did and I could not drive on the road for fear it would throw me off!I recently acquired an l2501 and added a grapple. It didn't take me long to recognize that some weight in the back would be beneficial. I'm debating filling the tires at some point but I wanted to know if there's any downside to it. Of course I get that the tractor is simply heavier which has its consequences at times but is there anything else?

Has anyone filled their tires with fluid and regretted it?

- Thread starter Virtual Guy

- Start date

BigG

Well-known member

Equipment

l2501, FEL, BB, Rotary cutter, rake,spreader, roller, etc. New Holland TL80 A

I am not trying to argue but this comes from the loader manual for my L2501.

Attachments

-

114.8 KB Views: 293

-

55 KB Views: 287

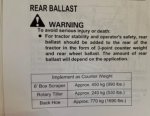

I certainly don't disagree with that - the loader requires the use of some form of rear ballast. From the LA525 loader manual that came with my 2021 L3901:I am not trying to argue but this comes from the loader manual for my L2501.

! WARNING

- For tractor stability and operator safety, rear ballast should be added to the rear of the tractor in the form of 3 point counter weight and rear wheel ballast. The amount of rear ballast will depend on the application.

I recently acquired an l2501 and added a grapple. It didn't take me long to recognize that some weight in the back would be beneficial. I'm debating filling the tires at some point but I wanted to know if there's any downside to it. Of course I get that the tractor is simply heavier which has its consequences at times but is there anything else?

OP, the only thing I would add is that I have filled tires in both my machines. I also have weights on the big girl…I added them before the tires was filled as I took delivery before the backho arrived and made agreement with dealer not to fill tires until after the BH…anyway she was helpless with out the loaded tires so I added the weights to hold me over. I’d do both the fluid and the weights all over again…know what I sayin’

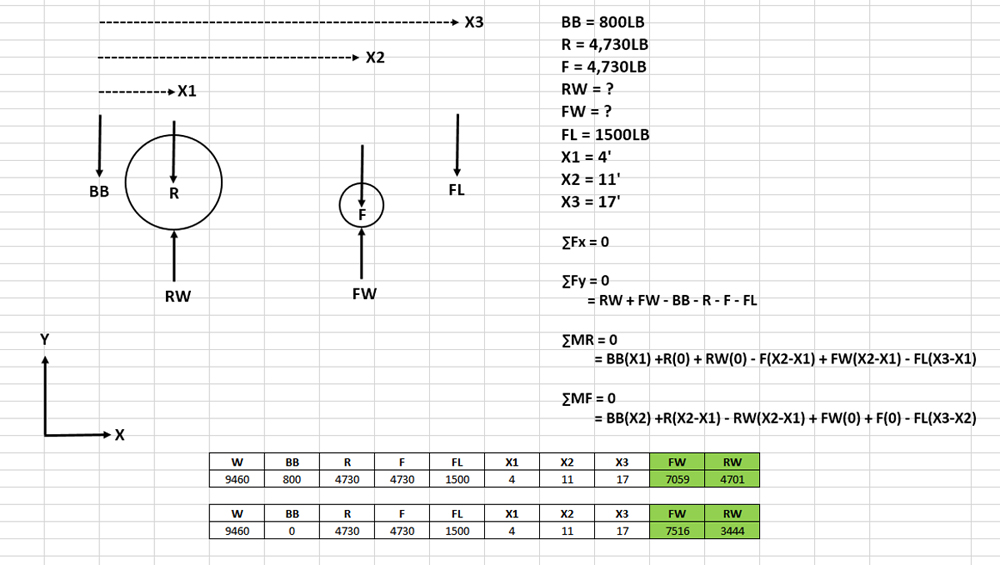

First off, you'd need to know the weight distribution on each axle without any additional load i.e. tractor + fel + front implement + liquid ballast + wheel weights + fuel before you can say anything meaningful.You need to use a weight on the rear of the 3 point. If you stop to figure the amount of weight that you are adding to the front axle when used as shown you will quickly realize that you are overloading the axle. The rear weight will transfer some of the weight to the much stronger rear axle.

Yes it will pick up the load but at what cost? Weighted tires and wheel weights improve the stability of the tractor but they do nothing to reduce the strain on the front axle.

Taking what I know about the weight of the tractor, the loader, the ballast and the wheel weights, and if I make the massive assumption that the weight distribution on each axle is 50/50 and assume that the disc harrow weighs 1,500lb, and then I sum the moments about each axle, I get the following:

The weight on the front axle without a rear ballast box or implement is 7,515lb. With an 800lb ballast box with the center of mass located 4ft behind the rear axle, the load on the front axle drops to 7,058lb.

So am I overloading the front axle? Without scales I have no idea what the weight distribution of the tractor is. With over 2,000lb added to the rear axle in the form of liquid ballast and wheel weights it might be 60% rear and 40% front which would change the numbers I mentioned above.

Are you sure? If adding liquid ballast and wheel weights changes the overall weight distribution on each axle, which it does, then it also changes the weight on the front axle when you pick something up.Weighted tires and wheel weights improve the stability of the tractor but they do nothing to reduce the strain on the front axle.

Using the example above, without any rear ballast box or implement, and with a 50/50 weight distribution, the load on the front axle is 7,516lb. With a 60/40 weight distribution favoring the rear axle, the load on the front axle drops to 6,570lb. That's about a 12.5% reduction in weight resulting from a change in weight distribution on each axle from adding liquid ballast and wheel weights.

BigG

Well-known member

Equipment

l2501, FEL, BB, Rotary cutter, rake,spreader, roller, etc. New Holland TL80 A

I do not think you are looking at the problem correctly. What you stated about the weight distribution between the front and rear axle would work if the weight (load) is added between the front and rear axles.Are you sure? If adding liquid ballast and wheel weights changes the overall weight distribution on each axle, which it does, then it also changes the weight on the front axle when you pick something up.

Using the example above, without any rear ballast box or implement, and with a 50/50 weight distribution, the load on the front axle is 7,516lb. With a 60/40 weight distribution favoring the rear axle, the load on the front axle drops to 6,570lb. That's about a 12.5% reduction in weight resulting from a change in weight distribution on each axle from adding liquid ballast and wheel weights.

When you place the load in front of the front axle there is no weight added to the rear axle. The load is added to the front axle as is acting as the fulcrum. The loaded tires and wheel weights do nothing to relieve the weight on the front axle. The only way to remove the weight from the front axle is to ballast behind the rear axle so that the rear axle acts as the fulcrum which in turn lessens the load on the front axle.

The wheel weights and the liquid in the tires become the heavy end of the see saw anchoring the rear of the tractor to the ground and this in turn allows the FEL to pick up more weight but it does nothing to lessen the load of the front axle.

Many larger tractors are used without the rear ballast. This is due to the fact that many of the loads picked up are not near the maximum lifting capacity of the tractor.

Please watch this as the tractor brand does not matter. The ballast concept is the most important safety feature you need before lifting heavy loads.

Last edited:

BigG

Well-known member

Equipment

l2501, FEL, BB, Rotary cutter, rake,spreader, roller, etc. New Holland TL80 A

I found this a pretty good demonstration of what I am trying to convey to you.

The ideal weight distribution for MFWD operation is 60/40 in favor of the rear axle. That distribution will vary considerably with the normal operational addition and subtraction of operating loads from both front and rear implements. I am confident the designers understand that and have engineered both axles to handle substantially more than their share of the load up to and well beyond the total allowable operating weight of the machine.Are you sure? If adding liquid ballast and wheel weights changes the overall weight distribution on each axle, which it does, then it also changes the weight on the front axle when you pick something up.

Using the example above, without any rear ballast box or implement, and with a 50/50 weight distribution, the load on the front axle is 7,516lb. With a 60/40 weight distribution favoring the rear axle, the load on the front axle drops to 6,570lb. That's about a 12.5% reduction in weight resulting from a change in weight distribution on each axle from adding liquid ballast and wheel weights.

If you want to worry about overloading anything the tires would be a good candidate. Unlike the axles they have a published load rating.

Dan

Last edited:

You aren't reading what I stated. Go back and actually read what I wrote. I never stated that just adding weight in front of the front axle added weight to the rear axle. These are the two points that I made.I do not think you are looking at the problem correctly.

1. Adding liquid ballast and rear wheel weights changes the weight distribution for each axle

2. The starting weight distribution on each axle affects the load on the front axle for a given weight

In case anyone is interested, I put together this FBD to help in calculating the reactionary forces at the ground under each tire. Basically solving for RW (rear weight) and FW (front weight) under the condition of static equilibrium. The two scenarios below show the change in axle load with the addition of an 800lb weight added to the rear. This also assumes a 50/50 weight distribution as indicated by R and F being equal.

It seems intuitive that as long as RW is greater than zero the tractor won't tip forward.

It seems intuitive that as long as RW is greater than zero the tractor won't tip forward.

BigG

Well-known member

Equipment

l2501, FEL, BB, Rotary cutter, rake,spreader, roller, etc. New Holland TL80 A

Listen to this video as he explains the need for ballast, to prevent wear and increase safety.

Look at the JD videos as they explain the need for 3 point ballast because the iron rear wheel and liquid ballast are not enough to transfer the weight to the rear axle. Look at the rear wheels bouncing off the ground at the 4:45 mark of the New Holland video. The weight of the bucket was NOT transferred to the rear axle in any way.

There is a reason JD is paying out money to the family for not informing them to add ballast to the tractor.

I was only trying to inform you and others that the proper ballast at and behind the rear axle is very important. The ballast becomes even more important with heavy loads and on slopes. When the rear axle lifts up you are now setting on a single pivot point until the bucket touches the ground. That is not a fun time.

You will do as you want. I run with ballasted tires and rear weights to prevent undue wear and increased stability thus safety. With several thousands of hours on several different tractors I have learned to learn from my mistakes as well as others including my father with over 40 years of experience in surface mining as a machine operator an well as a life time of farming.

Look at the JD videos as they explain the need for 3 point ballast because the iron rear wheel and liquid ballast are not enough to transfer the weight to the rear axle. Look at the rear wheels bouncing off the ground at the 4:45 mark of the New Holland video. The weight of the bucket was NOT transferred to the rear axle in any way.

There is a reason JD is paying out money to the family for not informing them to add ballast to the tractor.

I was only trying to inform you and others that the proper ballast at and behind the rear axle is very important. The ballast becomes even more important with heavy loads and on slopes. When the rear axle lifts up you are now setting on a single pivot point until the bucket touches the ground. That is not a fun time.

You will do as you want. I run with ballasted tires and rear weights to prevent undue wear and increased stability thus safety. With several thousands of hours on several different tractors I have learned to learn from my mistakes as well as others including my father with over 40 years of experience in surface mining as a machine operator an well as a life time of farming.

Low Lander

New member

Equipment

1980 B6100 4WD, 2005 TG1860 mower and 2020 1025R JD w/FEL & BH, 2016 GR2120

I filled the rear tires on my little JD1025R. I love it. 40 gallons of windshield washer fluid added almost 300lbs of weight as ballast. It is more stable and even rides better. Added 3” BORA spacers and increased use ability even more. My B6100 has tubes in it. I won’t do it since it doesn’t have a loader. Added 100lbs of weigh on the front end. I highly recommend liquid ballast in rear tires. Did mine with 2 three foot 1/4” hoses in less than an hour for only about $60 bucks.

I have no idea who you're arguing with.Listen to this video as he explains the need for ballast, to prevent wear and increase safety.

Look at the JD videos as they explain the need for 3 point ballast because the iron rear wheel and liquid ballast are not enough to transfer the weight to the rear axle. Look at the rear wheels bouncing off the ground at the 4:45 mark of the New Holland video. The weight of the bucket was NOT transferred to the rear axle in any way.

There is a reason JD is paying out money to the family for not informing them to add ballast to the tractor.

I was only trying to inform you and others that the proper ballast at and behind the rear axle is very important. The ballast becomes even more important with heavy loads and on slopes. When the rear axle lifts up you are now setting on a single pivot point until the bucket touches the ground. That is not a fun time.

It's basic physics, my friends.

If you add weight to the rear axle using filled tires or rear wheel weights, the fulcrum becomes the front axle.

If you add weight (s) on the 3 point hitch, with weights or a rotary cutter or ballast box or whatever, your fulcrum becomes both the front and rear axles combined. Because the rear weight is pushed back beyond the rear axle. With weight distribution being the denominator of which axle carries the most weight.

Because you're lifting a load on the FEL or FORKS etc, that load is beyond or farther forward than the front axle. If you're concerned with weight on the front axle, use weight behind the rear axle in the 3 point to counter balance and distribute the weight more evenly btwn both front and rear axles.

If you just want to keep your tractor from flipping forward, filled tires and wheel weights will help. If you want to balance the load more evenly front to back, load up the 3 point hitch.

FWIW... Most tractor manufacturers overbuild the axles.

If you add weight to the rear axle using filled tires or rear wheel weights, the fulcrum becomes the front axle.

If you add weight (s) on the 3 point hitch, with weights or a rotary cutter or ballast box or whatever, your fulcrum becomes both the front and rear axles combined. Because the rear weight is pushed back beyond the rear axle. With weight distribution being the denominator of which axle carries the most weight.

Because you're lifting a load on the FEL or FORKS etc, that load is beyond or farther forward than the front axle. If you're concerned with weight on the front axle, use weight behind the rear axle in the 3 point to counter balance and distribute the weight more evenly btwn both front and rear axles.

If you just want to keep your tractor from flipping forward, filled tires and wheel weights will help. If you want to balance the load more evenly front to back, load up the 3 point hitch.

FWIW... Most tractor manufacturers overbuild the axles.

Last edited:

Virtual Guy

Member

Equipment

Kubota L2501, loader, Land Pride box blade and grapple, John Deere MX5 cutter

I love that my comment stirred up such a great discussion. I appreciate all the input and info and I'm definitely more knowledgeable for it.

So I've learned that the only downside that matters to me is losing the inability to handle a filled tire if I get a leak. That's a concern as I don't currently know of a mobile service for that.

Pretty sure I get the difference in weight at the rear axel and behind it. I would have assumed that the front axel could take what the loader can lift but that apparently isn't exactly correct...most likely an issue over time.

If I fill my tires it'll be with something non-corrosive, likely rutabaga juice... or whatever its called. I'm looking into home spun 3-pt ballasts or possibly adding weights to my BB. I doubt I'll buy a dedicated box unless I found a really cheap used one.

So I've learned that the only downside that matters to me is losing the inability to handle a filled tire if I get a leak. That's a concern as I don't currently know of a mobile service for that.

Pretty sure I get the difference in weight at the rear axel and behind it. I would have assumed that the front axel could take what the loader can lift but that apparently isn't exactly correct...most likely an issue over time.

If I fill my tires it'll be with something non-corrosive, likely rutabaga juice... or whatever its called. I'm looking into home spun 3-pt ballasts or possibly adding weights to my BB. I doubt I'll buy a dedicated box unless I found a really cheap used one.

Most tire shops (at least around here) that arnt specifically automotive, do heavy equipment and tractors. They also fill tires so are pretty used ro working with bigger and filled tires.Ok so a question for those of you with filled tires. How do you fix a leak? I have a tire shop near by but I doubt they're willing to manipulate a several hundred pound tire and I SURE won't want to try.

Also, I like the idea of adding weight to my box blade. Is there a reason I can't just hang weights on it?

I typically just plug them myself. If I'm really worried about it, I'll drain the beat juice out, dismount, clean up the inside and install a patch plug. It's pretty much what your comfortable doing and what equipment you have around.

Windshield washer fluid is pretty light, actually lighter then a gallon of water. Last time I checked washer fluid was getting close to the $4.00 per gallon mark and this spring I paid just over that for a gallon of rim guard.I'm not sure if you have dirt/gravel driveways, but do you find that the loaded r1's rip them up? Im not ruling out loading them in the future, but thats one of main concerns besides sinking in mud. Also anyone loaded theirs with windshield washer fluid, I heard that is an option too, I'm not sure how effective that is.

Good to know, I was not aware!Windshield washer fluid is pretty light, actually lighter then a gallon of water. Last time I checked washer fluid was getting close to the $4.00 per gallon mark and this spring I paid just over that for a gallon of rim guard.