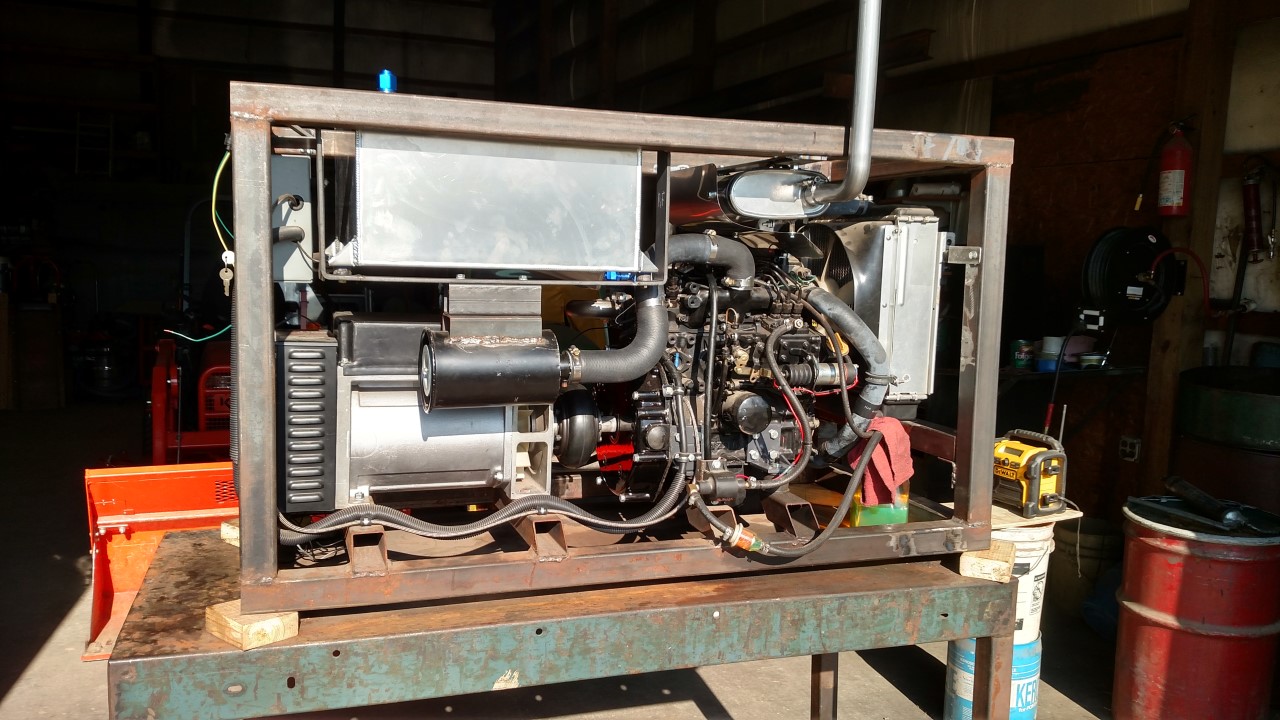

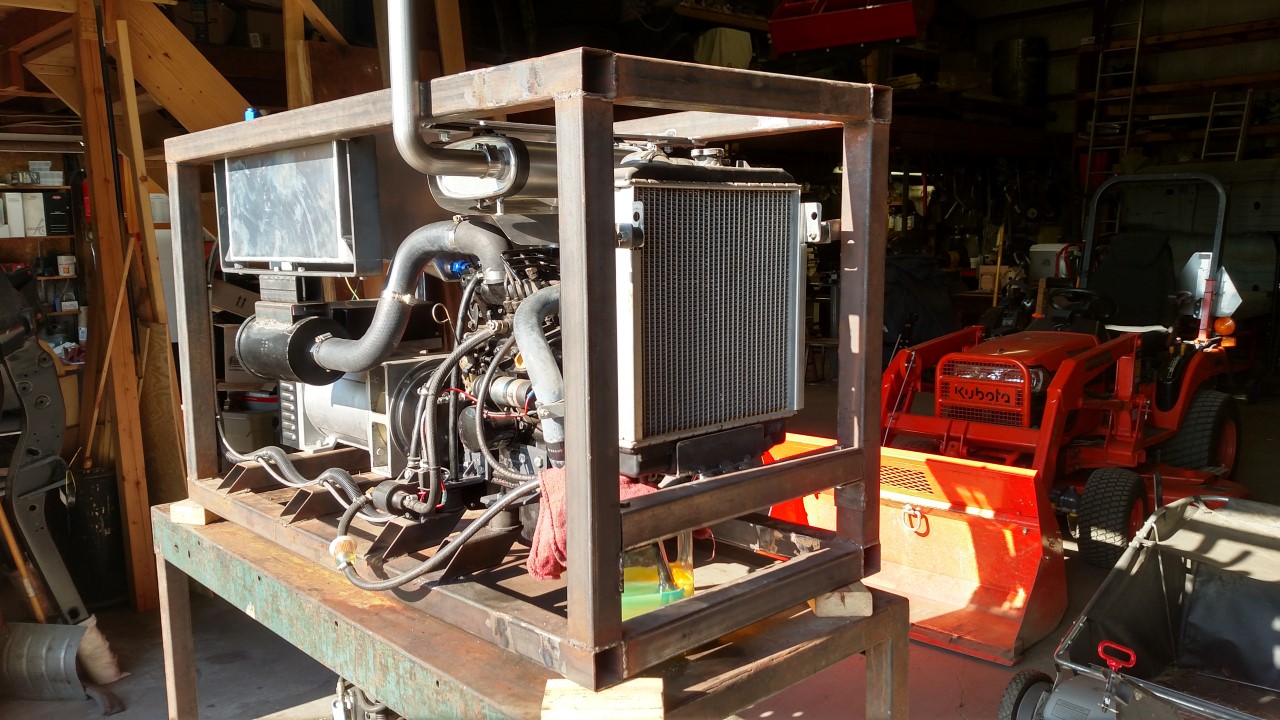

About 17 years ago, we were having a lot of power outages in my area, most likely due to a strained power grid in the area. The last 30 years has seen a huge increase in the population in my area, several hundred acres of farm land turned into housing projects. So, after being out of power for a couple of hours to over a day on several occasions, I started building a 10KW generator set powered by a Yanmar 3TNA72 22 hp diesel. The engine came out of a JD compact tractor that had the intake air hose come off and ingested some dust. It was replaced under warranty and I bought it from the dealer for a couple hundred bucks. It only had around 30 hours on it, so I tore it down, deglazed the cylinders (there were only a few minor scratched in them), put in new rings, bearings and gaskets.

I built a frame out of 2" X 2" 11 ga. tube, mounted the engine and radiator and got it running. It ran great, now problems with it at all. I bought a 10KW generator from then Northern Hydraulics, and mounted it behind the engine. I had a stub shaft machined that attached to the flywheel and used a Lovejoy coupling to connect them. I made sure they were as close to perfectly aligned as possible and made a couple of test runs that went fine. Then I ran it up to wide open, 3600 rpm, the governed engine speed and the required speed for the generator, and BANG! The lovejoy coupling disintegrated, sheared all the drive lugs off both pieces. Never did figure out what happened, but when the coupling went, it bent the shaft on the generator. Got disgusted and rolled it to the back of the shop and kind of lost interest in it. Shortly thereafter, the utility company upgraded the power grid in the area. the only time we lose power now is when some idiot knocks down a power pole or if a storm takes it out.

Having recently retired and working through some of my many neglected projects, I pulled it out and decided to finally get it finished up so I could use it if needed.

I pulled the generator off and dial indicated the shaft for runout. It had .045" of wobble. I wasn't sure if it could be straightened, so I pulled the rotor out of it and 3D printed some stands to support the bearings so I could indicate where the shaft was bent. I figured out how the get it into my shop press and gradually use increasing amounts of force to straighten it. About four hours and 14 trips to and from the press to check the runout, I finally got it down to .001" and figured that was good enough. Put it back together and it looked good, should do the job.

I decided a Lovejoy coupling wasn't going to be trusted again, so I started looking for another drive coupling that would be more robust and not fly apart at 3600 rpm. I found one on McMaster-Carr that used a rubber "tire" clamped between two drive plates that is rated for 80 ft lbs at 4000 rpm. Looked a lot more capable than the Lovejoy. Once I got it, and looked it over, I was sure it would work quite well. I built a stinger for the bucket on the Kubota to set the generator back in the frame and got the engine and generator shafts lined up within about .020" (the coupling allows up to .125" misalignment), I installed the coupling.

With fingers crossed, I started it up and gradually brought the rpm up to wide open. It was very smooth, no vibration at all. I made a half dozen runs, a couple with loads on the generator, and everything was good.

So for the last few weeks I have been finishing it up, new aluminum fuel tank, stainless steel exhaust, relocated intake and air fllter, repositioned radiator mount and some electrical changes. I also decided to put an axle and tires under it, and a removable ball hitch, so it can be towed. I bought a new 2,000" axle with springs and tires at a local surplus yard. Had to cut it down 11" to narrow the spring centers to 22" to fit the cage. I also bought a generator control box that will control the throttle and allow it to run at idle for a period of time before it goes to wide open. I put on a TinyTach yesterday as so far I only had an old Stewart-Warner mechanical tach to check the rpms, It shows right at 3600 rpm, just exactly what I needed.

I got some fittings today for the braided stainless fuel lines I'm going to install. I'll work on that this weekend.

I have a friend that might be able to make louvered panels to enclose it, if he can get his press finished. If not, I have to see what I can come up with to enclose it. And I'm going to put a lift point on the top also, in case it is needed.

After I get it all finished up, I'll take it all apart and get the frame and panels blasted and powder coated, might even have it done in Kubota orange or dark gray.

If I need it, I can trip the main breaker in the house(yes, I have an interlock installed) and plug it in an 230 volt outlet in the shop and it will easily power anything I have. With the wheels and hitch, if someone else needs it, it's ready to go.

I built a frame out of 2" X 2" 11 ga. tube, mounted the engine and radiator and got it running. It ran great, now problems with it at all. I bought a 10KW generator from then Northern Hydraulics, and mounted it behind the engine. I had a stub shaft machined that attached to the flywheel and used a Lovejoy coupling to connect them. I made sure they were as close to perfectly aligned as possible and made a couple of test runs that went fine. Then I ran it up to wide open, 3600 rpm, the governed engine speed and the required speed for the generator, and BANG! The lovejoy coupling disintegrated, sheared all the drive lugs off both pieces. Never did figure out what happened, but when the coupling went, it bent the shaft on the generator. Got disgusted and rolled it to the back of the shop and kind of lost interest in it. Shortly thereafter, the utility company upgraded the power grid in the area. the only time we lose power now is when some idiot knocks down a power pole or if a storm takes it out.

Having recently retired and working through some of my many neglected projects, I pulled it out and decided to finally get it finished up so I could use it if needed.

I pulled the generator off and dial indicated the shaft for runout. It had .045" of wobble. I wasn't sure if it could be straightened, so I pulled the rotor out of it and 3D printed some stands to support the bearings so I could indicate where the shaft was bent. I figured out how the get it into my shop press and gradually use increasing amounts of force to straighten it. About four hours and 14 trips to and from the press to check the runout, I finally got it down to .001" and figured that was good enough. Put it back together and it looked good, should do the job.

I decided a Lovejoy coupling wasn't going to be trusted again, so I started looking for another drive coupling that would be more robust and not fly apart at 3600 rpm. I found one on McMaster-Carr that used a rubber "tire" clamped between two drive plates that is rated for 80 ft lbs at 4000 rpm. Looked a lot more capable than the Lovejoy. Once I got it, and looked it over, I was sure it would work quite well. I built a stinger for the bucket on the Kubota to set the generator back in the frame and got the engine and generator shafts lined up within about .020" (the coupling allows up to .125" misalignment), I installed the coupling.

With fingers crossed, I started it up and gradually brought the rpm up to wide open. It was very smooth, no vibration at all. I made a half dozen runs, a couple with loads on the generator, and everything was good.

So for the last few weeks I have been finishing it up, new aluminum fuel tank, stainless steel exhaust, relocated intake and air fllter, repositioned radiator mount and some electrical changes. I also decided to put an axle and tires under it, and a removable ball hitch, so it can be towed. I bought a new 2,000" axle with springs and tires at a local surplus yard. Had to cut it down 11" to narrow the spring centers to 22" to fit the cage. I also bought a generator control box that will control the throttle and allow it to run at idle for a period of time before it goes to wide open. I put on a TinyTach yesterday as so far I only had an old Stewart-Warner mechanical tach to check the rpms, It shows right at 3600 rpm, just exactly what I needed.

I got some fittings today for the braided stainless fuel lines I'm going to install. I'll work on that this weekend.

I have a friend that might be able to make louvered panels to enclose it, if he can get his press finished. If not, I have to see what I can come up with to enclose it. And I'm going to put a lift point on the top also, in case it is needed.

After I get it all finished up, I'll take it all apart and get the frame and panels blasted and powder coated, might even have it done in Kubota orange or dark gray.

If I need it, I can trip the main breaker in the house(yes, I have an interlock installed) and plug it in an 230 volt outlet in the shop and it will easily power anything I have. With the wheels and hitch, if someone else needs it, it's ready to go.