When using the rotary mower with my M5140 occasionally I have to back up to get out of a tight spot. The mower is running at 540 RPM and the engine around 2300. I'm concerned that I should not clutch at that high of an RPM but also using the shuttle shift without clutching would seem worse. Should I back off the RPMs when reversing or just clutch, shuttle shift to reverse, backup, clutch and shuttle shift back into forward. Any advice much appreciated.

clutching at high RPMs

- Thread starter longleaf1

- Start date

It's actually not all that bad if your PTO puts power back into the transmission from the back side. Both sides of the plate would not lose all that much relative velocity to each other (Engine powering one side, Mower flywheel effect powering the other) so I wouldn't be worried about the actual engine RPM's unless you dramatically change them while the clutch is engaged (like go from 2400 to 1200) and then re-engage, that will put a bit of wear on the clutch. That's about the same with any fly-wheeling PTO implement though.

However, these are pretty tough clutches and should be able to handle changes like that. If you're worried, ease into it fairly quickly and it should be good to go.

There's a Youtube video where a guy starts his tractor with his pickup and a strap wrapped around the PTO implement shaft. While I would never recommend that, it actually demonstrates the feedback system of the PTO quite dramatically.

However, these are pretty tough clutches and should be able to handle changes like that. If you're worried, ease into it fairly quickly and it should be good to go.

There's a Youtube video where a guy starts his tractor with his pickup and a strap wrapped around the PTO implement shaft. While I would never recommend that, it actually demonstrates the feedback system of the PTO quite dramatically.

TripleR

Active member

Equipment

BX2200, BX2660, L5740 HSTC, M8540HDC and some other tractors and equipment

We operate our tractors like that and have for years, never had any problems with synch or hydraulic shuttle. We do a lot of direction changes on our levies.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

I take it you have the mechanical shuttle version and not the hydraulic, as with the hydraulic you don't need to manually clutch.When using the rotary mower with my M5140 occasionally I have to back up to get out of a tight spot. The mower is running at 540 RPM and the engine around 2300. I'm concerned that I should not clutch at that high of an RPM but also using the shuttle shift without clutching would seem worse. Should I back off the RPMs when reversing or just clutch, shuttle shift to reverse, backup, clutch and shuttle shift back into forward. Any advice much appreciated.

On that model the PTO is direct driven from the motor to a hydraulic clutch pack that is not effected by the mechanical clutch, hence the PTO stays at speed when pushing in the mechanical clutch.

So no dropping out the mechanical clutch at high RPM's and then reengaging it after switching direction with the shuttle is quite within its specs of normal operation.

Shaun,It's actually not all that bad if your PTO puts power back into the transmission from the back side. Both sides of the plate would not lose all that much relative velocity to each other (Engine powering one side, Mower flywheel effect powering the other).

On a newer tractor that can't happen, the one way clutch on the PTO shaft will not let power / turns transmit back to the flywheel, it just free wheels.

That's why I said "if" early in my comment. I didn't know if his was that way or not.Shaun,

On a newer tractor that can't happen, the one way clutch on the PTO shaft will not let power / turns transmit back to the flywheel, it just free wheels.

Tallahassee Kubota Man

New member

Equipment

M5140HD/LA1153/LandPride RCF2072/DirtDog disc/RakeMaster grapple/Caroni tiller

I've got the M5140 w/hydraulic shuttle. Good explanation Wolfman.

Longleaf1, what I do is use the foot throttle when I'm in situations that require quick backwards/forwards change. I can throttle down much easier and quicker that way. Actually I use the foot throttle a lot of the time except when mowing, harrowing, etc in a large field where I have little change in rpm.

Longleaf1, what I do is use the foot throttle when I'm in situations that require quick backwards/forwards change. I can throttle down much easier and quicker that way. Actually I use the foot throttle a lot of the time except when mowing, harrowing, etc in a large field where I have little change in rpm.

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

I think a little more explanation is needed on this statement:It's actually not all that bad if your PTO puts power back into the transmission from the back side.

I sorry but I completely disagree, it is extremely bad, especially in this operators scenario.

If the PTO were to be transferring power back to the clutch it would make it nearly impossible to shift the tractor out of gear let alone shift it into reverse, as the entire transmission would still be being powered, just from the implement and not from the motor.

This is exactly why one way clutches are imperative to add to older tractors, newer tractors already have them built into the PTO drive.

Clarification, if I'm reading right would be this:

You have three kinds of loads on a clutch, rotational, pressure and shock. All three cause a form of wear on them.

The PTO also has a clutch that usually disengages first on most older tractors. I can't speak for the new stuff, I had assumed it was the same. The transmission when the main clutch is released (even if the transmission is at a dead standstill which I'm not sure it is at all times the clutches are pushed in since the mechanisms themselves would have a flywheel effect) starts to engage. This creates all 3 forms of stress, however, if you have a flywheel going on the PTO and are close to the same RPMS as you were when the clutches were disengaged, as the PTO clutch comes back in, the flywheel effect will help reduce/remove the shock and rotational forces on the main clutch plate. So the PTO in flywheel mode can actually help reduce the loads on the main plate if the conditions are appropriate. I would assume they'd hurt it if you had the wrong conditions.

This is how I had it explained to me, and why I was told to be careful in changing engine speeds with the PTO clutch disengaged because coming back in the flywheel effect can lurch the tractor if you're not careful (wrong conditions).

Since I have directly experienced that with all the older tractors I've driven, I know something is doing it.

If you have a better explanation, I'd love to be corrected on it.

Here's the video I was referring to (and it looks like a pretty modern tractor)

https://www.youtube.com/watch?v=ae_4it5gJJg

You have three kinds of loads on a clutch, rotational, pressure and shock. All three cause a form of wear on them.

The PTO also has a clutch that usually disengages first on most older tractors. I can't speak for the new stuff, I had assumed it was the same. The transmission when the main clutch is released (even if the transmission is at a dead standstill which I'm not sure it is at all times the clutches are pushed in since the mechanisms themselves would have a flywheel effect) starts to engage. This creates all 3 forms of stress, however, if you have a flywheel going on the PTO and are close to the same RPMS as you were when the clutches were disengaged, as the PTO clutch comes back in, the flywheel effect will help reduce/remove the shock and rotational forces on the main clutch plate. So the PTO in flywheel mode can actually help reduce the loads on the main plate if the conditions are appropriate. I would assume they'd hurt it if you had the wrong conditions.

This is how I had it explained to me, and why I was told to be careful in changing engine speeds with the PTO clutch disengaged because coming back in the flywheel effect can lurch the tractor if you're not careful (wrong conditions).

Since I have directly experienced that with all the older tractors I've driven, I know something is doing it.

If you have a better explanation, I'd love to be corrected on it.

Here's the video I was referring to (and it looks like a pretty modern tractor)

https://www.youtube.com/watch?v=ae_4it5gJJg

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Most older tractors only have one clutch disk that operates both the Transmission and the PTO.

Kubota was one of the early pioneers of the 2 stage clutch, one for the Transmission and one for the PTO.

You're video reference is a cheap Chinese tractor, Not a Kubota, one should not try and learn things from stupid You Tube videos, it not good for anyone's brain!

It doesn't matter how new or old a tractor is, It just matters who built it and what components were put into it. That tractor in the video does not have a one way clutch in it, and the mower he has on it will keep pushing the tractor when he pushes in the clutch, very cheap and poor design.

Go out and try to start your tractor like that, on your L3200, it can't be done!

Maybe on your Allis Chalmers, but not the Kubota.

You can not turn the PTO the proper direction and turn the motor, (yes you could turn it the opposite direction, but why would you want to do that?).

It's been this way on Kubota's way back to the days of the B7100's.

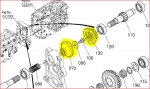

L3200 One way clutch:

Kubota was one of the early pioneers of the 2 stage clutch, one for the Transmission and one for the PTO.

You're video reference is a cheap Chinese tractor, Not a Kubota, one should not try and learn things from stupid You Tube videos, it not good for anyone's brain!

It doesn't matter how new or old a tractor is, It just matters who built it and what components were put into it. That tractor in the video does not have a one way clutch in it, and the mower he has on it will keep pushing the tractor when he pushes in the clutch, very cheap and poor design.

Go out and try to start your tractor like that, on your L3200, it can't be done!

Maybe on your Allis Chalmers, but not the Kubota.

You can not turn the PTO the proper direction and turn the motor, (yes you could turn it the opposite direction, but why would you want to do that?).

It's been this way on Kubota's way back to the days of the B7100's.

L3200 One way clutch:

Attachments

-

81.4 KB Views: 1,178

The Allis-Chalmers doesn't have any active PTO, it's a dedicated FEL and BH.

The Oliver I routinely drive does work that way with the PTO. It's two stage, I don't know how it works the PTO and the main clutch but they are separate. You push in the clutch just a little and the PTO disengages, letting you continue to drive the tractor around. The PTO if running a mower will flywheel. If you push the clutch all the way in, the transmission decouples and you can shift. You then bring in the main clutch and the PTO follows as you fully release it giving the benefits (and risks) I mentioned.

I did not know how long Kubota has been doing one-way's, that's interesting that they've been doing it for so long. Love this site, I learn more all the time.

Thanks Wolfman.

The Oliver I routinely drive does work that way with the PTO. It's two stage, I don't know how it works the PTO and the main clutch but they are separate. You push in the clutch just a little and the PTO disengages, letting you continue to drive the tractor around. The PTO if running a mower will flywheel. If you push the clutch all the way in, the transmission decouples and you can shift. You then bring in the main clutch and the PTO follows as you fully release it giving the benefits (and risks) I mentioned.

I did not know how long Kubota has been doing one-way's, that's interesting that they've been doing it for so long. Love this site, I learn more all the time.

Thanks Wolfman.