I bought a lock on coupler for my air powered grease gun. No more fighting the grease going in. Worked great as u only need one hand now and even a stubborn fitting will have to take the grease.

BX23S backhoe noise - hydraulic or mechanical

- Thread starter Waywest

- Start date

It is still under warranty. While I had the dipper cylinder decoupled I was not able to move dipper arm because the bucket was supported by the ground. Previously with no pressure and engine off and pulling dipper lever I was able to move Arm +| - 2” from a resting position and no noise.

Ordered pins, zerks, spacers and grease lock-on device for grease gun. for this pivot position.

You all have been great. Like good neighbors! I really appreciate your guidance and suggestions.

Next I will replace zerk.

Any further detail on scenario to replace the pin? Laying arm flat on wood while it is attached to tractor? How about using new pin to push out old pin ( but don’t want to mushroom new pin). Type of hammer? I like the idea of a socket head. But, needs to be easier to move than first time or I will change orientation because something must still be creating a load on pin.

Thanks

Ordered pins, zerks, spacers and grease lock-on device for grease gun. for this pivot position.

You all have been great. Like good neighbors! I really appreciate your guidance and suggestions.

Next I will replace zerk.

Any further detail on scenario to replace the pin? Laying arm flat on wood while it is attached to tractor? How about using new pin to push out old pin ( but don’t want to mushroom new pin). Type of hammer? I like the idea of a socket head. But, needs to be easier to move than first time or I will change orientation because something must still be creating a load on pin.

Thanks

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

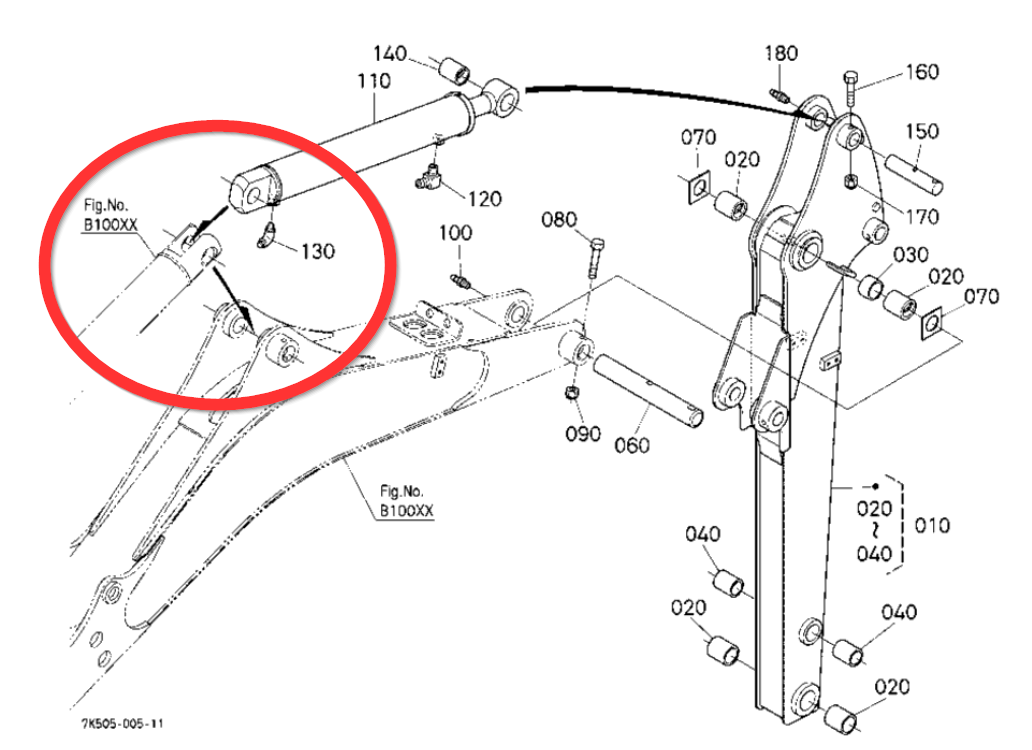

Looking at the single picture with your finger.....

Get a socket that fits nicely into the 'depression' or 'crater' between the zerk and the outer rim, add and extension,or two to be longer than the total width( maybe 6" + 3" extensions ?), use a 4# mini sledge, and use good,firm whacks, say 2-3...and see how far it moves. repeat as required,just be sure to keep socket firm and flat against the 'crater' bottom. The idea is to put concentrated forcenear the centerline of the pin. Having the socket in the crater eliminates the chance of whacking the 'bushing' and/or 'mushrooming' the actual pin. If need be, add another extension to keep precious fingers OUT of harms way !!!

Be well aware that once you push it past the end of the ram connection, it will MOVE. Probably best to do this with it all 'stretched out' on the ground, maybe solid wooden blocks , hear and there ,as required , to keep from moving too far. Safety first...If it takes an hour or 2 to figure out a safe way...it's time very well spent. When installing the new pin... fill with grease first( to be sure it accepts it ) and test fit on the bushing only( no ram end). it should be silky smooth. If not ,remove any burrs or ridges, try again. THEN install and push through the ram end. Maybe have a helper move the correct lever so the ram can get aligned with the bushings. I suspect if everything is well gresaed and aligned ,it'll slide in easily.

Get a socket that fits nicely into the 'depression' or 'crater' between the zerk and the outer rim, add and extension,or two to be longer than the total width( maybe 6" + 3" extensions ?), use a 4# mini sledge, and use good,firm whacks, say 2-3...and see how far it moves. repeat as required,just be sure to keep socket firm and flat against the 'crater' bottom. The idea is to put concentrated forcenear the centerline of the pin. Having the socket in the crater eliminates the chance of whacking the 'bushing' and/or 'mushrooming' the actual pin. If need be, add another extension to keep precious fingers OUT of harms way !!!

Be well aware that once you push it past the end of the ram connection, it will MOVE. Probably best to do this with it all 'stretched out' on the ground, maybe solid wooden blocks , hear and there ,as required , to keep from moving too far. Safety first...If it takes an hour or 2 to figure out a safe way...it's time very well spent. When installing the new pin... fill with grease first( to be sure it accepts it ) and test fit on the bushing only( no ram end). it should be silky smooth. If not ,remove any burrs or ridges, try again. THEN install and push through the ram end. Maybe have a helper move the correct lever so the ram can get aligned with the bushings. I suspect if everything is well gresaed and aligned ,it'll slide in easily.

Make sure your zerk fitting is good,I had to replace one from factory because I noticed it was hard to get grease into it was painted kubota orange, pulled it out and it looked okay but I put a new one in anyways then greased and it was night and day

baronetm

Member

Equipment

L3901HST w/FEL, 3rd fnct. BH77 BH, 5' Bushhog, 6' BBL, 42" Forks, WoodMaxx WM-8H

I would take a different approach, before removing the pin.

1. Remove the old zerk.

2. Get a long drill bit slightly smaller in diameter and longer than the grease gallery and by hand clean out the old grease, notice if it is dryed out. No drill bit try a stiff wire and grind slots into the end similar to a drill bit with a cut off tool. I have also put a light weight oil, 3 in one or kerosene into the grease hole, inserted a new zerk and apply grease, the light weight oil helped to soften the remaining hardened grease.

3. Install a new zerk and grease to see if the new grease will purge the remaining old grease from the the gallery cross drilling.

4. The below listed grease zerk cleaner may also work.

5. I have seen pins in industrial applications with the cross drilling not matching the center drilling, a blind hole, a manufacturing defect.

Another long shot possibility for the noise is a leaking hydraulic piston packing. My BH77 with 3 hours on the hoe had a squeal in the curl cylinder, it sounded a bit like a rusty door hinge. My issue also showed in time with a quickly drooping bucket and no ability to hold a load it for more than a 20-30 seconds, it also made the squeal in both directions but not every time.

One more thought, as a mechanical procedure never hit a steel pin with another steel object, always use a metal that is softer than the material you want to remove, i.e, brass, bronze or aluminum.

www.northerntool.com

www.northerntool.com

Looking forward to hear the final diagnosis.

1. Remove the old zerk.

2. Get a long drill bit slightly smaller in diameter and longer than the grease gallery and by hand clean out the old grease, notice if it is dryed out. No drill bit try a stiff wire and grind slots into the end similar to a drill bit with a cut off tool. I have also put a light weight oil, 3 in one or kerosene into the grease hole, inserted a new zerk and apply grease, the light weight oil helped to soften the remaining hardened grease.

3. Install a new zerk and grease to see if the new grease will purge the remaining old grease from the the gallery cross drilling.

4. The below listed grease zerk cleaner may also work.

5. I have seen pins in industrial applications with the cross drilling not matching the center drilling, a blind hole, a manufacturing defect.

Another long shot possibility for the noise is a leaking hydraulic piston packing. My BH77 with 3 hours on the hoe had a squeal in the curl cylinder, it sounded a bit like a rusty door hinge. My issue also showed in time with a quickly drooping bucket and no ability to hold a load it for more than a 20-30 seconds, it also made the squeal in both directions but not every time.

One more thought, as a mechanical procedure never hit a steel pin with another steel object, always use a metal that is softer than the material you want to remove, i.e, brass, bronze or aluminum.

Roughneck Grease Fitting Unblocker | Northern Tool

The Roughneck® Grease Fitting Unblocker is an effective tool to open clogged grease fittings and loosen hardened grease joints. User fills...

Looking forward to hear the final diagnosis.

Curious, did replacing the pin solve the noise issue? I have the same noise from the same general location on my BH92. I've greased the heck out of it but the grease seems to only extrude from the right side of the joint. After greasing, the noise returns soon after use. Thanks!It is still under warranty. While I had the dipper cylinder decoupled I was not able to move dipper arm because the bucket was supported by the ground. Previously with no pressure and engine off and pulling dipper lever I was able to move Arm +| - 2” from a resting position and no noise.

Ordered pins, zerks, spacers and grease lock-on device for grease gun. for this pivot position.

You all have been great. Like good neighbors! I really appreciate your guidance and suggestions.

Next I will replace zerk.

Any further detail on scenario to replace the pin? Laying arm flat on wood while it is attached to tractor? How about using new pin to push out old pin ( but don’t want to mushroom new pin). Type of hammer? I like the idea of a socket head. But, needs to be easier to move than first time or I will change orientation because something must still be creating a load on pin.

Thanks

My BH70 with thumb had the wrong pin, length was wrong and it wasn't drilled for grease. You might want to pull the pin and see if it is just another screwup out of the Georgia plant, and your dealer didn't catch it.Curious, did replacing the pin solve the noise issue? I have the same noise from the same general location on my BH92. I've greased the heck out of it but the grease seems to only extrude from the right side of the joint. After greasing, the noise returns soon after use. Thanks!

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

iD.

grease needs to be coming out both sides.

best to remove pin, clean it, grease it through Zerk,confirm it works properly,then reinstall, add more grease

grease needs to be coming out both sides.

best to remove pin, clean it, grease it through Zerk,confirm it works properly,then reinstall, add more grease

Thanks for the reply. I just got off the phone with the dealer's mechanic. He suggested that I also take a look at the pin as you suggested. He said that sometimes they don't get enough grease on the whole pin at the factory, then it rusts on one side causing the grease not to flow evenly from side to side.My BH70 with thumb had the wrong pin, length was wrong and it wasn't drilled for grease. You might want to pull the pin and see if it is just another screwup out of the Georgia plant, and your dealer didn't catch it.

Update

This past weekend I moved the dipper arm pivot pin out in both directions, evaluated, cleaned and greased. Same noise. I then removed the pin from the top dipper cylinder in order to check the dipper arm movement, and doin so I found that the noise was actually coming from the base end of the dipper cylinder. In fact, trying to rotate the cylinder up and out of the dipper arm socket was difficult, for two reasons. One: it was not in perfect alignment with the dipper arm. Two: it was binding somehow at the base of the cylinder where it connects to the boom cylinder. I was able to rotate the dipper arm cylinder up, and as I did it produced the same noise I've been hearing. Once I got the cylinder rotated up as far as it would go, the noise and bind was gone! I could now rotate the cylinder up and down without issue. I proceeded to grease the pin at the base of the dipper cylinder (again), and reconnect to the top of the dipper arm. It took some pressure to push it back into place due to the misalignment, but once it was all put back together, no noises. The question is what was causing the binding and noise at the joint where the two cylinders (dipper and boom) connect? If it returns, I will evaluate that pin. Maybe the noise is because of the alignment issue, I don't know.

This past weekend I moved the dipper arm pivot pin out in both directions, evaluated, cleaned and greased. Same noise. I then removed the pin from the top dipper cylinder in order to check the dipper arm movement, and doin so I found that the noise was actually coming from the base end of the dipper cylinder. In fact, trying to rotate the cylinder up and out of the dipper arm socket was difficult, for two reasons. One: it was not in perfect alignment with the dipper arm. Two: it was binding somehow at the base of the cylinder where it connects to the boom cylinder. I was able to rotate the dipper arm cylinder up, and as I did it produced the same noise I've been hearing. Once I got the cylinder rotated up as far as it would go, the noise and bind was gone! I could now rotate the cylinder up and down without issue. I proceeded to grease the pin at the base of the dipper cylinder (again), and reconnect to the top of the dipper arm. It took some pressure to push it back into place due to the misalignment, but once it was all put back together, no noises. The question is what was causing the binding and noise at the joint where the two cylinders (dipper and boom) connect? If it returns, I will evaluate that pin. Maybe the noise is because of the alignment issue, I don't know.

Can't tell for sure from a photo, but it appears that the dipper cylinder may be bent, also, the dipper may be bent. You need to disassemble both parts and have a machine shop inspect them checking for straightness and holes not being perpendicular. Continuing to operate with bent parts will cause rapid wear. I wouldn't trust the manufacturer to produce quality parts or a dealer to properly inspect them.

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

Could damage (bends ) have been caused by using the bucket to 'whack' something like a tree stump or 'aggressively' turning/moving tractor with the backhoe ???

hard to tell in pictures, but my old eyes don't see the cylinder/ram being bent rather the boom or arm or dipper stick......whatever the orange steel is called....

hard to tell in pictures, but my old eyes don't see the cylinder/ram being bent rather the boom or arm or dipper stick......whatever the orange steel is called....

Thanks for the reply Lynnmore. The cylinder didn't appear to be bent, but very hard to tell with the naked eye. I may hold my level up to it and see if there are any noticeable gaps.Can't tell for sure from a photo, but it appears that the dipper cylinder may be bent, also, the dipper may be bent. You need to disassemble both parts and have a machine shop inspect them checking for straightness and holes not being perpendicular. Continuing to operate with bent parts will cause rapid wear. I wouldn't trust the manufacturer to produce quality parts or a dealer to properly inspect them.

Thanks for the reply GreensvilleJay. It could be more likely than not, that I did bend the dipper arm somehow. I have used the backhoe to reposition the tractor multiple times while digging. I will definitely make it a point NOT to do that anymore. I picked up that technique from Dad when he had his John Deere 310 backhoe. I suppose those heavy duty purpose build machines are build to take it.Could damage (bends ) have been caused by using the bucket to 'whack' something like a tree stump or 'aggressively' turning/moving tractor with the backhoe ???

hard to tell in pictures, but my old eyes don't see the cylinder/ram being bent rather the boom or arm or dipper stick......whatever the orange steel is called....