Have a 4WD M8200 and just bought our third 4WD/BiSteering hydraulic valve.

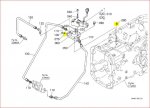

The 4WD solenoid coil is so hot when energized that you can barely keep your fingers on it. Kubota Corporate has no answer for me. They won't sell the solenoid coil separate and you have to buy the whole valve. It's pretty expensive. The dealer told me to check the diodes. I see diodes on the schematic but I can't find them yet. Anyway, I just ran 12v from the battery to the solenoid coil... It get's hot so there is no question of a diode being involved. If I reverse the polarity there is no change... It still gets hot. If I run 12v to the other solenoid coil, next to it on the same valve (the Bi Speed one) it does not get hot. My understanding of dc solenoids is that the inrush current is the same as the holding current, so there should be no question about the valve not stroking to it's full travel. Do I seem to be the only one to be burning up 4WD/Bi Speed solenoids???

The 4WD solenoid coil is so hot when energized that you can barely keep your fingers on it. Kubota Corporate has no answer for me. They won't sell the solenoid coil separate and you have to buy the whole valve. It's pretty expensive. The dealer told me to check the diodes. I see diodes on the schematic but I can't find them yet. Anyway, I just ran 12v from the battery to the solenoid coil... It get's hot so there is no question of a diode being involved. If I reverse the polarity there is no change... It still gets hot. If I run 12v to the other solenoid coil, next to it on the same valve (the Bi Speed one) it does not get hot. My understanding of dc solenoids is that the inrush current is the same as the holding current, so there should be no question about the valve not stroking to it's full travel. Do I seem to be the only one to be burning up 4WD/Bi Speed solenoids???