I got an older B7100D tractor not too long ago. When I lifted the 3 point then put the control valve in the neutral position, it would fade down to the ground. Tore it all apart and discovered the o-ring on the piston was the wrong size (too small) so I replaced it with a bigger one and put it all back together. Well, now the 3 point will lift when I pull back on the lever if the revs are high enough on the engine but if idling will drop when I pull back (same direction). The good news is that it holds up in the neutral position now so I've got that going for me. What would cause it to both lift and drop with the lever in the same position, depending on rpms? I pulled it back apart and don't see anything obvious but it's my first time working on a tractor like this so who knows? Maybe it just needs a good bleed? Thanks!

B7100 Three Point Control Valve

- Thread starter tomwagner44

- Start date

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Typically the 3ph will fall if the lever is moved to the raise position IF there is another hydraulically powered implement with the control actuated.

So my guess is that there is a leak in the system somewhere upstream preventing pressurization at low rpm. Either that or the hydraulic pump is weak.

So my guess is that there is a leak in the system somewhere upstream preventing pressurization at low rpm. Either that or the hydraulic pump is weak.

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

When you shift the valve to raise you are getting a pressure drop at the cylinder work port due to the low flow rate at idle. I don't know the details of the 3pt control valve on the B7100 but normally there is a load check on the cylinder that prevents that pressure drop from allowing the load to drop. The load check keeps the work port to the cylinder closed until pump inlet pressure at the port rises to equal the load pressure on the cylinder side. Then the inlet pressure overcomes the load check and the load raises without dropping. I will see if I can find a schematic of the B7100 valve./circuit to see if it has a load check.I got an older B7100D tractor not too long ago. When I lifted the 3 point then put the control valve in the neutral position, it would fade down to the ground. Tore it all apart and discovered the o-ring on the piston was the wrong size (too small) so I replaced it with a bigger one and put it all back together. Well, now the 3 point will lift when I pull back on the lever if the revs are high enough on the engine but if idling will drop when I pull back (same direction). The good news is that it holds up in the neutral position now so I've got that going for me. What would cause it to both lift and drop with the lever in the same position, depending on rpms? I pulled it back apart and don't see anything obvious but it's my first time working on a tractor like this so who knows? Maybe it just needs a good bleed? Thanks!

EDIT: The WSM for the B7100 is not very detailed. Off the top of my head I did not see anything I could ID as a load check.

Dan

Last edited:

Thanks Dan. It was working when I took it apart (except for the blade drop/fade in neutral). I was hoping for some sort of schematic to make sure I put it back together properly. Interestingly, nothing happens when I shift the valve into the raise position. It raises when I place it in the lowering position with the rpms up and lowers with the valve in the same position with the rpms dropped. Could be that I have it backwards (forward position is raise??). In the forward position (what I believe to be the raise position) nothing happens at all.When you shift the valve to raise you are getting a pressure drop at the cylinder work port due to the low flow rate at idle. I don't know the details of the 3pt control valve on the B7100 but normally there is a load check on the cylinder that prevents that pressure drop from allowing the load to drop. The load check keeps the work port to the cylinder closed until pump inlet pressure at the port rises to equal the load pressure on the cylinder side. Then the inlet pressure overcomes the load check and the load raises without dropping. I will see if I can find a schematic of the B7100 valve./circuit to see if it has a load check.

EDIT: The WSM for the B7100 is not very detailed. Off the top of my head I did not see anything I could ID as a load check.

Dan

Sorry if it sounds confusing. It is. All I really did was change the o-ring on the piston. I've been working on cars, machinery, motorcycles, etc for years and can usually figure out how stuff works but this one has me stumped.

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

Now I am really confused. The implement control lever is working in reverse?Thanks Dan. It was working when I took it apart (except for the blade drop/fade in neutral). I was hoping for some sort of schematic to make sure I put it back together properly. Interestingly, nothing happens when I shift the valve into the raise position. It raises when I place it in the lowering position with the rpms up and lowers with the valve in the same position with the rpms dropped. Could be that I have it backwards (forward position is raise??). In the forward position (what I believe to be the raise position) nothing happens at all.

Sorry if it sounds confusing. It is. All I really did was change the o-ring on the piston. I've been working on cars, machinery, motorcycles, etc for years and can usually figure out how stuff works but this one has me stumped.

Dan

Ok, just figured out that the control lever is working properly from a directional standpoint. Back is up and forward is down. But, the lowering (down) function doesn't work. The 3pt blade will lower when the tractor is idling or not running and I pull the lever back (up position).Now I am really confused. The implement control lever is working in reverse?

Dan

The only thing I might have screwed up when I took it apart is a little check valve type set up that sits under the front cap of the lever housing. There's a spring, ball bearing, sleeve, small piston looking thing and a washer that sit "under" a threaded plug. Does that sound familiar? That's the part I want the schematic for.

Last edited:

Got it. There is an adjuster bolt on the top of the housing. Found someone on another thread with the same issue and that was their solution so I tried it and Bingo! Still wants to fade when the idle is low and I move the lever to the lift position so that's another issue for another day (weak pump) but at least it is functional for now. Let the chores begin!!Typically the 3ph will fall if the lever is moved to the raise position IF there is another hydraulically powered implement with the control actuated.

So my guess is that there is a leak in the system somewhere upstream preventing pressurization at low rpm. Either that or the hydraulic pump is weak.

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

Lets home in here a bit. When you say the 3pt lowers do you mean it dips a bit and stops or that it actually drops to the ground?Ok, just figured out that the control lever is working properly from a directional standpoint. Back is up and forward is down. But, the lowering (down) function doesn't work. The 3pt blade will lower when the tractor is idling or not running and I pull the lever back (up position).

The only thing I might have screwed up when I took it apart is a little check valve type set up that sits under the front cap of the lever housing. There's a spring, ball bearing, sleeve, small piston looking thing and a washer that sit "under" a threaded plug. Does that sound familiar? That's the part I want the schematic for.

Tha little poppet valve is quite possibly the load check I mentioned earlier. If it is a load check and not working the lift might well drop to the ground when you move the lever to the raise position. That opens the pump to the cylinder and if there is no or insufficient pump pressure at that port the lift will move down.

Dan

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

There's no load check on the B7100. If the 3ph lever is in the raise position at the same time as an upstream implement control lever is moved (eg: left FEL control in "float" and attempt to raise 3ph further) the 3ph will drop like a rock.Tha little poppet valve is quite possibly the load check I mentioned earlier. If it is a load check and not working the lift might well drop to the ground when you move the lever to the raise position. That opens the pump to the cylinder and if there is no or insufficient pump pressure at that port the lift will move down.

I believe the bolt he is now adjusting is the lowering speed control valve. Probably seated it when he reassembled things so it closed off the return completely instead of just restricting it.

The spring loaded ball on the front of the control valve is the pressure relief valve.

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

So this is normal behavior?There's no load check on the B7100. If the 3ph lever is in the raise position at the same time as an upstream implement control lever is moved (eg: left FEL control in "float" and attempt to raise 3ph further) the 3ph will drop like a rock.

I believe the bolt he is now adjusting is the lowering speed control valve. Probably seated it when he reassembled things so it closed off the return completely instead of just restricting it.

The spring loaded ball on the front of the control valve is the pressure relief valve.

Dan

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

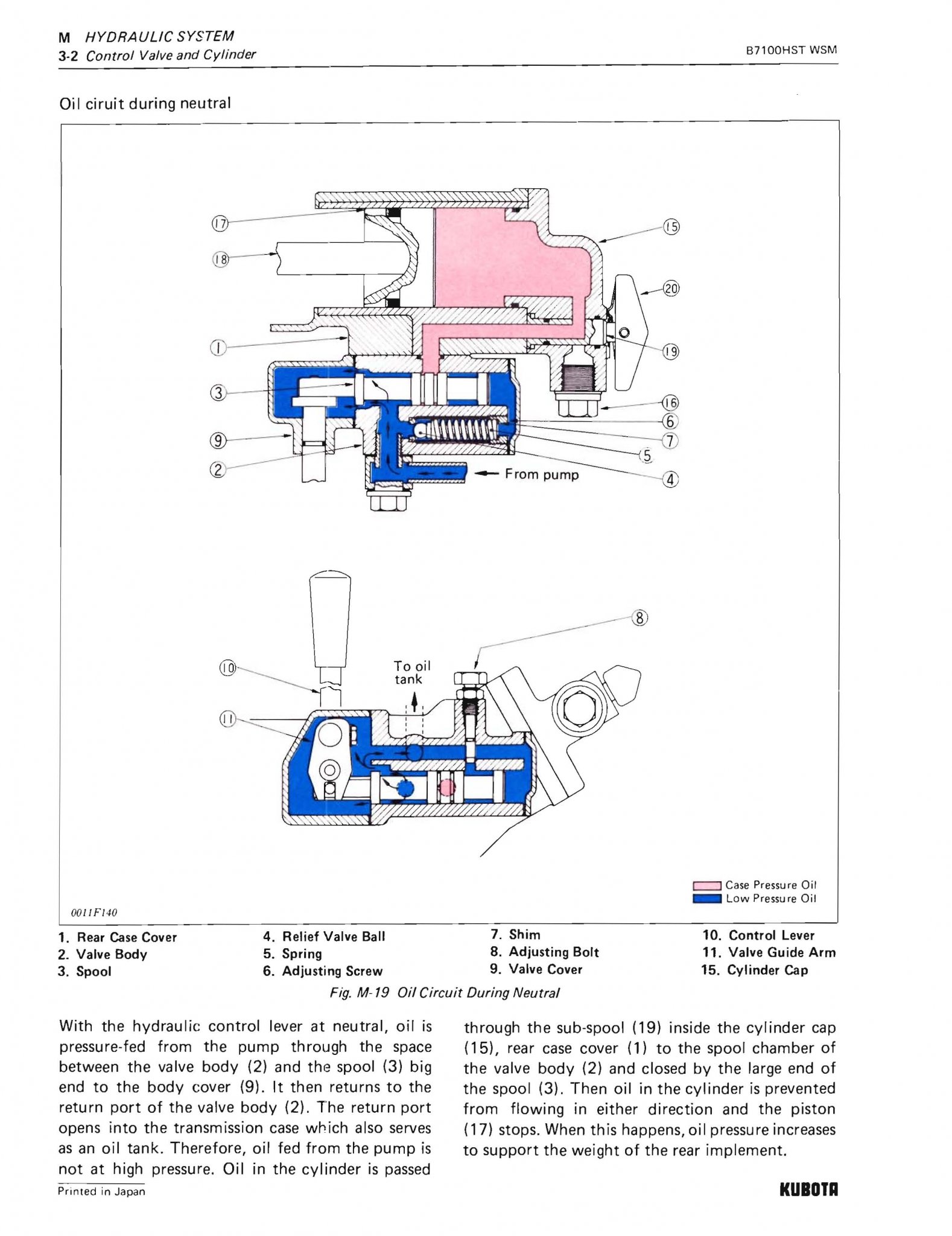

The WSM has a series of diagrams documenting each case (up, down, overload, etc.) here is the page for Neutral, which shows the components:

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

It shouldn't drop if the system is sealed upstream. He never mentioned having any other hydraulic implements upstream, which is why I suspect either a leak or worn pump -- something that would explain why the system can't develop enough pressure at idle to keep the 3ph raised.So this is normal behavior?

Dan

It might take forever for the system to build sufficient pressure to raise an implement at idle, but the engine will stall before the implement will drop. The fact that the engine continues to idle while the 3ph drops tells me either the pump is worn out or the fluid is going somewhere else.

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

Thanks. I found the drawings and descriptions of operation. It looks like he "fixed" the issue by decreasing the lowering speed which reduces the amount of drop when he shifts the control lever.The WSM has a series of diagrams documenting each case (up, down, overload, etc.) here is the page for Neutral, which shows the components:

View attachment 82248

Dan

Last edited:

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

I did not read his description as the lift won't raise at idle - just that it initially drops when he move the lever to raise. There are multiple potential pressure loss situations with that system.It shouldn't drop if the system is sealed upstream. He never mentioned having any other hydraulic implements upstream, which is why I suspect either a leak or worn pump -- something that would explain why the system can't develop enough pressure at idle to keep the 3ph raised.

It might take forever for the system to build sufficient pressure to raise an implement at idle, but the engine will stall before the implement will drop. The fact that the engine continues to idle while the 3ph drops tells me either the pump is worn out or the fluid is going somewhere else.

There is always going to be an instantaneous pressure drop when the 3pt valve opens and the load may momentarily drift.

The pump flow at idle is tiny so that drift probably gets magnified.

If the pump is worn drift may be even worse because of bypassing in the pump.

If the 3pt spool is worn you get spool leakage to tank.

When the engine is off cylinder pressure can and will flow through the pump in reverse.

All of that is why check valves and/or load checks have become standard practice.

Dan

Last edited:

torch

Well-known member

Equipment

B7100HSD, B2789, B2550, B4672, 48" cultivator, homemade FEL and Cab

Well, now the 3 point will lift when I pull back on the lever if the revs are high enough on the engine but if idling will drop when I pull back (same direction).

The 3pt blade will lower when the tractor is idling or not running and I pull the lever back (up position).

From this chain, I had the impression that it fell at idle and rose at high rpm when the lever was pulled back, however it would not drop when the lever was pushed forward until he opened the lowering speed valve to allow fluid through.Got it. There is an adjuster bolt on the top of the housing. Found someone on another thread with the same issue and that was their solution so I tried it and Bingo! Still wants to fade when the idle is low and I move the lever to the lift position

A load check would prevent the 3ph from falling at idle, but until he opened the lowering valve, he never would have been able to lower it! <lol>

Ok, seriously, the B7100 was designed in the 70's. Nice little workhorse, but not much in the way of bells and whistles. ;-)