Dan_R_42

Member

Equipment

B7100-D, w/ Sims Cab, B219 FEL, ARPS 70 Backhoe, Oversized R4 Tires, LX2610 Cab

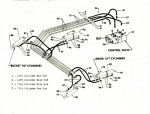

I was just told by my local Kubota dealer that for my B7100 - B219 loader, replacements for the metal oil lines, have been Mfg Discontinued. I'm referring to the four metal lines that mount to the Lift Frame Assembly.

Has anyone had to replace any or all of these lines? Were you able to find a vendor that could makeup metal replacement lines? Did you have to change over to hydraulic hoses to replace these lines. I'm thinking the hydraulic hoses would be too bulky to neatly install on the lift frame. The lines I'm referring to are #80 & #81.

Wondering if anyone else has had to deal with this issue...

Thanks, Dan

Has anyone had to replace any or all of these lines? Were you able to find a vendor that could makeup metal replacement lines? Did you have to change over to hydraulic hoses to replace these lines. I'm thinking the hydraulic hoses would be too bulky to neatly install on the lift frame. The lines I'm referring to are #80 & #81.

Wondering if anyone else has had to deal with this issue...

Thanks, Dan

Attachments

-

86.2 KB Views: 524

-

47.3 KB Views: 376

Last edited: