i have a b7100 and the 3 pt hitch bleeds down can anyone help me with why this is and how to fix . cleand screen and replaced fluid but still scraching my head as to why it keeps bleeding down helppp...

b7100 3 pt bleed down

- Thread starter willsmit

- Start date

They all do that. Its a pretty common question and hot topic here on OTT. So far no known fix or cure as to why the 3pth leeks down. The B series and the L series both do it.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

What kind of time frame are we talking about? With my nearly 400lb box blade on, it is barely noticeable at all while in use..... but it will drop to the ground overnight.

When I got the tractor, it would lift just fine, but would immediately drop to the ground when the lift handle was released. I replaced the o-ring & backup ring on the lift piston, and cured it completely. It was about $13 in parts, if I remember right.

When I got the tractor, it would lift just fine, but would immediately drop to the ground when the lift handle was released. I replaced the o-ring & backup ring on the lift piston, and cured it completely. It was about $13 in parts, if I remember right.

Yes. I'd say the same thing as Lil Foot.

The O-rings are worn. Just a tiny 1 micron mark on the O-ring and it will leak.

The O-rings are worn. Just a tiny 1 micron mark on the O-ring and it will leak.

i have a b7100 and the 3 pt hitch bleeds down can anyone help me with why this is and how to fix . cleand screen and replaced fluid but still scraching my head as to why it keeps bleeding down helppp...

thanks to everyone you guys are grate and this site is to no to menny places you can go and get help any more so thank you and i will replace the o-ring as soon as i get over the gout it got me by the big toe.

Willsmit.. Your welcome. Hope you feel better soon.

thanks to everyone you guys are grate and this site is to no to menny places you can go and get help any more so thank you and i will replace the o-ring as soon as i get over the gout it got me by the big toe.

hey guys o-rings worked great it stays up thank you so much all of you guy are great thank you again

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

So far - the OTT have inspired and helped a lot, but maybe I have reached my personal limit..

On my B6100 I have a 3 pt sliding down (slowly). But how do I get hold of the piston?

The piston is "stuck". in a very low position. See pic I will swap the O rings on the cylinder head, but I need to find the correct dimensions.

But is there any way to get hold of the piston without taking more apart?

Also - does the workshop handbook cover my serial number (29611)

On my B6100 I have a 3 pt sliding down (slowly). But how do I get hold of the piston?

The piston is "stuck". in a very low position. See pic I will swap the O rings on the cylinder head, but I need to find the correct dimensions.

But is there any way to get hold of the piston without taking more apart?

Also - does the workshop handbook cover my serial number (29611)

Attachments

-

94.4 KB Views: 650

-

91 KB Views: 611

When I just did the b6000 I detached the lift arms on the 3ph and manually raised them. This pushed the cylinder head out. I kept working the lift arms and after a bit the piston hit the cylinder wall and give me enough traction on the cylinder to push it out a bit further. That allowed me to get it up far enough to grab hold and pull it out with my hands.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Right!The piston needs to come out frontwise right?

I did mine with just the cover removed as your pics show..... I lifted the 3pt arms to raise the piston to the top, & then stuck a big strong magnet on it & pulled it out. Be sure to liberally lube with hydraulic fluid before re-installing it...... looks like it would be easy to damage the new o-ring if it went in dry.

I also put a dab of grease on the end of the piston rod before re-assembly.

Hmmm......I didn't make it this time - I almost got hold of the piston out when I heard a BANG and the lift arms fell down with a sound "of no return". I can feel (when moving the arms up&down) something inside the lift cover is wrong.

I can feel (when moving the arms up&down) something inside the lift cover is wrong.

It looks like the piston is a wee bit out of line. And it is stuck. Really stuck.

I guess I'll have to try to find some help on this. Hydraulics is really not my best area.

It looks like the piston is a wee bit out of line. And it is stuck. Really stuck.

I guess I'll have to try to find some help on this. Hydraulics is really not my best area.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

I'm embarrassed.

The "bang" you heard sounds like the piston rod, which is connected to the lift arms, has dropped out of the recess in the back of the piston and the cylinder bore. In my earlier post I said:

"I used the 3pt arms to raise the piston to the top"

The rod dropping out of the bore would be no big deal, (I did the same thing while playing around with mine) I just fished it back into position with one of those spring-loaded fingers retrievers. However, I did that with the piston out.... I don't understand how the piston is stuck, unless it was pushed all the way out of the bottom of the bore & the o-ring is now preventing it from coming back up. I'd be careful about driving it this way, not sure if the rod could hang low enough to interfere with anything else.

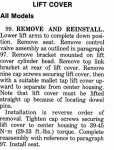

If it were me, I would remove the lift cover, which should give complete access to everything involved. Looks like only one gasket, and the manual says it's pretty straight forward:

The "bang" you heard sounds like the piston rod, which is connected to the lift arms, has dropped out of the recess in the back of the piston and the cylinder bore. In my earlier post I said:

What I should have said (and thought I did) is something like:I lifted the 3pt arms to raise the piston to the top

"I used the 3pt arms to raise the piston to the top"

The rod dropping out of the bore would be no big deal, (I did the same thing while playing around with mine) I just fished it back into position with one of those spring-loaded fingers retrievers. However, I did that with the piston out.... I don't understand how the piston is stuck, unless it was pushed all the way out of the bottom of the bore & the o-ring is now preventing it from coming back up. I'd be careful about driving it this way, not sure if the rod could hang low enough to interfere with anything else.

If it were me, I would remove the lift cover, which should give complete access to everything involved. Looks like only one gasket, and the manual says it's pretty straight forward:

Attachments

-

92.2 KB Views: 533

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Lil Foot, first of all - dont´t be embarrased! I used the arms to lift (as you said) and the piston came almost but not quite up. When trying to get a grip (?) of the piston I heard a bang and the arms hit the floor...

Secondly I really appreciate your supportive effort! Tomorrow mornng starts in the garage with the lift cover. Thanks again for the drawings.

Secondly I really appreciate your supportive effort! Tomorrow mornng starts in the garage with the lift cover. Thanks again for the drawings.

Finally I am done..

Thanks to all you guys. To lift the entire cover was really not tricky except for some stuck bolts. They are now replaced and so is a set of O rings.

In my case the piston wouldn´t come out just by lifting the arms. the rod inside the piston didn´t push far enough. But the surfaces looked really good so there is no damage.

Thanks to all you guys. To lift the entire cover was really not tricky except for some stuck bolts. They are now replaced and so is a set of O rings.

In my case the piston wouldn´t come out just by lifting the arms. the rod inside the piston didn´t push far enough. But the surfaces looked really good so there is no damage.