I removed the horizontal spring in front of the start safety switch completely. Very easy to do and then hosed the entire area with wd-40, and greased the shaft that is directly ahead. It seemed very dry and I can see why the guy on U-Tube drilled and tapped for additional zerks. After the rain quit I took the tractor out for a spin and much, much better. The remaining 2 vertical springs provide enough pressure to keep the start switch functional. Great tip for those with the same issue!

B2601 Treadle Pedal hard to use

- Thread starter Frankb

- Start date

I just hauled about 20 ton of modified from one end of my 2 acre property to the other end. My right knee was so sore at the end of the day. I was NOT happy. I just removed the spring so now I'm actually looking forward to moving the next 10 ton of stone that I need to finish the pad for my garage.

RichBob, when you say it was very easy to remove the spring, can you explain exactly how? I am used to my pedal finally but this glitch annoys me. BUT I have little mechanical ability.I removed the horizontal spring in front of the start safety switch completely. Very easy to do and then hosed the entire area with wd-40, and greased the shaft that is directly ahead. It seemed very dry and I can see why the guy on U-Tube drilled and tapped for additional zerks. After the rain quit I took the tractor out for a spin and much, much better. The remaining 2 vertical springs provide enough pressure to keep the start switch functional. Great tip for those with the same issue!

I do my basic services okay, following instructions, pictures, and sometimes with help from here and YouTube!

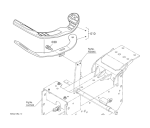

On the left side of the tractor (brake pedal side) you will see 3 springs, 2 vertical and one more horizontal behind the first 2. This one is the one I removed with just a small pair of vice grips. this spring is 2 or maybe 3 inches long.RichBob, when you say it was very easy to remove the spring, can you explain exactly how? I am used to my pedal finally but this glitch annoys me. BUT I have little mechanical ability.

I do my basic services okay, following instructions, pictures, and sometimes with help from here and YouTube!

I added a grease fitting and bent the back of the pedal up a half inch or so. Day and night difference.Check to see if there is a ZERK fitting - if so (I would hope so) HAS it been greased? If not grease it and see if that makes any difference.

Attachments

-

514.2 KB Views: 394

-

471.7 KB Views: 385

Foxrunfarms

Well-known member

Equipment

Kubota LX2610, 1951 Farmall M, 1967 John Deere 110 Rf, 2010 Arctic Cat 700

I agree. On surgery #3 with the knee and that was one thing that kind of pushed me away from looking at a Kubota right away and leaning towards other brands with thr pedals side by side. The price and rebates on attachments brought me back. For the whole Kubota package deal vs just a basic tractor of another color I decided I can have a sore knee.Just checked our new B2601 & no zerk on the hydro pedal linkage, but brake linkage has one. Been getting used to the heavy B2601 pedal compared to the BX we traded in. B2601 hydro pedal pivot point is slightly closer to back of pedal making reverse a little harder to actuate than forward.

FWIW

Instead of using vicegrips to grab springs, I use recoil cord. Loop it through the spring, then firmly pull, bracing hand on 'something ' solid. Never needed bandaids doing it this way in 4 decades.

Instead of using vicegrips to grab springs, I use recoil cord. Loop it through the spring, then firmly pull, bracing hand on 'something ' solid. Never needed bandaids doing it this way in 4 decades.

Hello gentlemen, this is my first post, but I've often read the forum. I joined in hope's that this might help somebody who has been through this same problem. My b2601 had the same horrible reverse pedal issue and after much research I was going to replace the 2 vertical springs when I found a simple solution. Just remove the horizontal spring located near the switch below and behind the 2 vertical springs. It takes less than a minute. Costs nothing. And has dropped the force needed to reverse by about 50%. The pedal still quickly returns to middle stop position. And it now feels like every other kubota I've operated. No pedal mods or other things are necessary. This linkage has 3 springs but works much much better with 2. I hope this helps somebody who is searching the net like I was. Have a good evening.

Definitely helped me a lot! Thank you, Terry. Can't understand for the life of me why they didn't put a grease zerk on the treadle pedal shaft, but gave us one on each end of the brake pedal!? Most of us use the brake occasionally as a parking brake or to help steer while backblading, but the treadle pedal is used non-stop. I wouldn't mind taking out the shaft to grease it every once in a while but that doesn't look to be an easy task. Maybe it's a nitpick, but I feel like Kubota failed us on this one.Hello gentlemen, this is my first post, but I've often read the forum. I joined in hope's that this might help somebody who has been through this same problem. My b2601 had the same horrible reverse pedal issue and after much research I was going to replace the 2 vertical springs when I found a simple solution. Just remove the horizontal spring located near the switch below and behind the 2 vertical springs. It takes less than a minute. Costs nothing. And has dropped the force needed to reverse by about 50%. The pedal still quickly returns to middle stop position. And it now feels like every other kubota I've operated. No pedal mods or other things are necessary. This linkage has 3 springs but works much much better with 2. I hope this helps somebody who is searching the net like I was. Have a good evening.

I can see why some B2601 folks are having a hard time with reverse compared to a tractor like my B2650HSDC.

The pedal pivot point on the B2601 is several inches away from the pedal itself forcing you to have to push down and back at the same time.

Compare that to the pivot point being directly under the pedal on the B2650HSDC so it's more like having to push down only.

The pedal pivot point on the B2601 is several inches away from the pedal itself forcing you to have to push down and back at the same time.

Compare that to the pivot point being directly under the pedal on the B2650HSDC so it's more like having to push down only.

Attachments

-

92.6 KB Views: 262

-

120.8 KB Views: 259

I drilled a very small hole in the tube approximately in the center so that a needle point on a grease gun will grease the shaft. To keep debris out I covered that hole with a hose clamp that is moved aside when greasing.Definitely helped me a lot! Thank you, Terry. Can't understand for the life of me why they didn't put a grease zerk on the treadle pedal shaft, but gave us one on each end of the brake pedal!? Most of us use the brake occasionally as a parking brake or to help steer while backblading, but the treadle pedal is used non-stop. I wouldn't mind taking out the shaft to grease it every once in a while but that doesn't look to be an easy task. Maybe it's a nitpick, but I feel like Kubota failed us on this one.

I like that idea, but are you able to push grease all the way to the ends of the shaft from a single hole in the center like you would be able to do with a grease zerk? If so, I'm reaching for my drill! Thanks for the reply.I drilled a very small hole in the tube approximately in the center so that a needle point on a grease gun will grease the shaft. To keep debris out I covered that hole with a hose clamp that is moved aside when greasing.

View attachment 120165

I'm definitely going to bend the pedal up like you did. Did you remove the pedal shaft to drill and tap for the grease zerk. I didn't study it too closely but it looks like a pain in the arse to remove the shaft.I added a grease fitting and bent the back of the pedal up a half inch or so. Day and night difference.

Yes, I have grease coming out both ends. The first time you use it move things a bit to help with the flow.I like that idea, but are you able to push grease all the way to the ends of the shaft from a single hole in the center like you would be able to do with a grease zerk? If so, I'm reaching for my drill! Thanks for the reply.

Awesome... I'm probably going to go that route as opposed to drilling and tapping for a grease zerk. I could always do that later on using the same hole. Thanks!Yes, I have grease coming out both ends. The first time you use it move things a bit to help with the flow.

Since the tubing is rather thin the threads for a grease zerk would be few, that is why I didn't go that route. If you countersink the hole just a bit the needle will seal better since the curve of the pipe won't allow a perfect fit, alternatively you could just use a center punch to form the sharp edge.Awesome... I'm probably going to go that route as opposed to drilling and tapping for a grease zerk. I could always do that later on using the same hole. Thanks!

This is a game changer! Glad this thread got bumped and so is my right knee. Took the spring off and used the tractor for about an hour and operated with no issues.

Thank you for sharing!

Thank you for sharing!

Hello gentlemen, this is my first post, but I've often read the forum. I joined in hope's that this might help somebody who has been through this same problem. My b2601 had the same horrible reverse pedal issue and after much research I was going to replace the 2 vertical springs when I found a simple solution. Just remove the horizontal spring located near the switch below and behind the 2 vertical springs. It takes less than a minute. Costs nothing. And has dropped the force needed to reverse by about 50%. The pedal still quickly returns to middle stop position. And it now feels like every other kubota I've operated. No pedal mods or other things are necessary. This linkage has 3 springs but works much much better with 2. I hope this helps somebody who is searching the net like I was. Have a good evening.

Next mod for my little B. Thanks for sharing.

Indeed my L is much easier to reverse with and more controlled as well. Not sure why big K decided the 50 lbs (or some equally silly number) of force would be needed to operate these B’s in reverse.

Indeed my L is much easier to reverse with and more controlled as well. Not sure why big K decided the 50 lbs (or some equally silly number) of force would be needed to operate these B’s in reverse.

Same for my B2301 with 26 hours. I removed the switch spring (the horizontal of the three), checked to be sure he interlock still worked properly, and sure enough, > 50% reduction in effort to move the treadle! Thanks for the tip!This is a game changer! Glad this thread got bumped and so is my right knee. Took the spring off and used the tractor for about an hour and operated with no issues.

Thank you for sharing!

I also removed my switch spring after my Achilles tendon started hurting shortly after buying my tractor.

Six months later, no more pain and no ill effects of removing the spring.

Six months later, no more pain and no ill effects of removing the spring.