Any Suggestions GREATLY appreciated!

My B2100 HST started dripping hydraulic fluid onto mower deck. Removed mower deck and been using as utility tractor.

After sitting for a while, EVERY TIME i needed to use it, and when parked would just sit and drip drip drip oil literallly for weeks. Then, I would have to add gallon to gallon and half of Hyd Fluid to get it on stick.

We have retired and now we cut our own grass… it would be handy for cutting in edge of woods, wife uses zero turn in yard.

IMPOSSIBLE to see leak due to frame totally enclosing transmission on left side. Used every conceivable way to see source, but to no avail.

Finally, bit the bullet and separated HST and rear end from frame of tractor. Thought the leak would undoubtedly be easy to see. Yep, that was not the case. Not a drip!

Needless to say, it took lots of hours to separate. I know nothing else to do to reveal the leak.

Does anyone have any ideas on how to “make it leak” like it has been for years?

I am attaching a couple of photos of the left side, the source of the leak when the tractor was together.

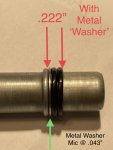

My only guesstimate would be a leak from the hydraulic tube that connects motor to HST… it is only a pipe with two ‘O’ rings inserted into holes on each end.

I am a very patient person and HATE to admit defeat, but this Orange has about done me in… and I will probably lose my sanity to put it back together and it start leaking again…

i am truly grateful for any responses!

My B2100 HST started dripping hydraulic fluid onto mower deck. Removed mower deck and been using as utility tractor.

After sitting for a while, EVERY TIME i needed to use it, and when parked would just sit and drip drip drip oil literallly for weeks. Then, I would have to add gallon to gallon and half of Hyd Fluid to get it on stick.

We have retired and now we cut our own grass… it would be handy for cutting in edge of woods, wife uses zero turn in yard.

IMPOSSIBLE to see leak due to frame totally enclosing transmission on left side. Used every conceivable way to see source, but to no avail.

Finally, bit the bullet and separated HST and rear end from frame of tractor. Thought the leak would undoubtedly be easy to see. Yep, that was not the case. Not a drip!

Needless to say, it took lots of hours to separate. I know nothing else to do to reveal the leak.

Does anyone have any ideas on how to “make it leak” like it has been for years?

I am attaching a couple of photos of the left side, the source of the leak when the tractor was together.

My only guesstimate would be a leak from the hydraulic tube that connects motor to HST… it is only a pipe with two ‘O’ rings inserted into holes on each end.

I am a very patient person and HATE to admit defeat, but this Orange has about done me in… and I will probably lose my sanity to put it back together and it start leaking again…

i am truly grateful for any responses!

Attachments

-

606.4 KB Views: 338

-

606.4 KB Views: 392