I'd like to add a bale clamp on the front end loader of my M4500DT. Currently it has one one-way valve, and one two-way valve both used for the front loader (single acting lift cylinders and double acting curl cylinder). So I need to add a two-way valve for the double acting bale clamp but I'm not sure of good options for doing this despite having done a bunch of internet searching.  The hydraulics are open circuit, 2700 psi max.

The hydraulics are open circuit, 2700 psi max.

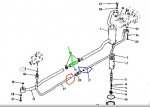

I'd prefer to keep this old beast looking original so my first choice would be to add a second Kubota 2 way valve in the current 2-valve bank. But according to my research I can't stack a third valve onto the existing 2 valves (the existing 2 way valve is sandwiched between the one-way valve and the gearbox casing and the ports don't look like they are compatible with stacking valves).

Another other option seems to be to add a mechanical joystick for the loader controls but I am uncertain about the terminology and do not want to end up getting the wrong one, so I am calling for help!

Does anyone have any suggestions or can refer me to any sites about whether:

(a) a mechanical (non-electrical) joystick is available that will do 3 functions (single acting lift, double acting curl, and double acting clamp) all in one joystick? If so, what's the terminology for such a thing so I can find it on the internet?

(I don't need a float function but would be happy to have it. My only objection to electrical joystick is the additonal complexity. I'm reasonably confident that I can mount the mechanical joystick where the plumbing won't get in the way.)

(b) how do I plumb the joystick into the existing system so I can still use the existing 2 valves for other functions without having to isolate the joystick from the 2 valves, not have a separate supply and return line? Would I have to make a power beyond adapter?

Thanks in advance for your help.

I'd prefer to keep this old beast looking original so my first choice would be to add a second Kubota 2 way valve in the current 2-valve bank. But according to my research I can't stack a third valve onto the existing 2 valves (the existing 2 way valve is sandwiched between the one-way valve and the gearbox casing and the ports don't look like they are compatible with stacking valves).

Another other option seems to be to add a mechanical joystick for the loader controls but I am uncertain about the terminology and do not want to end up getting the wrong one, so I am calling for help!

Does anyone have any suggestions or can refer me to any sites about whether:

(a) a mechanical (non-electrical) joystick is available that will do 3 functions (single acting lift, double acting curl, and double acting clamp) all in one joystick? If so, what's the terminology for such a thing so I can find it on the internet?

(I don't need a float function but would be happy to have it. My only objection to electrical joystick is the additonal complexity. I'm reasonably confident that I can mount the mechanical joystick where the plumbing won't get in the way.)

(b) how do I plumb the joystick into the existing system so I can still use the existing 2 valves for other functions without having to isolate the joystick from the 2 valves, not have a separate supply and return line? Would I have to make a power beyond adapter?

Thanks in advance for your help.