I have a B2601, about 2 years old. The position control range has never seemed quite right, and perhaps has gotten a little worse (hard to tell).

It is reaching the bottom of the 3ph range at position 4. The mower doesn't really start to lift till about 7. It only goes to 8. It doesn't seem to stop it working - I get full range of motion on the 3ph and on the mower. It just means I guess I get less fine control (and I don't really need fine control).

All of which is a way of saying this doesn't need fixing. But it annoys me.

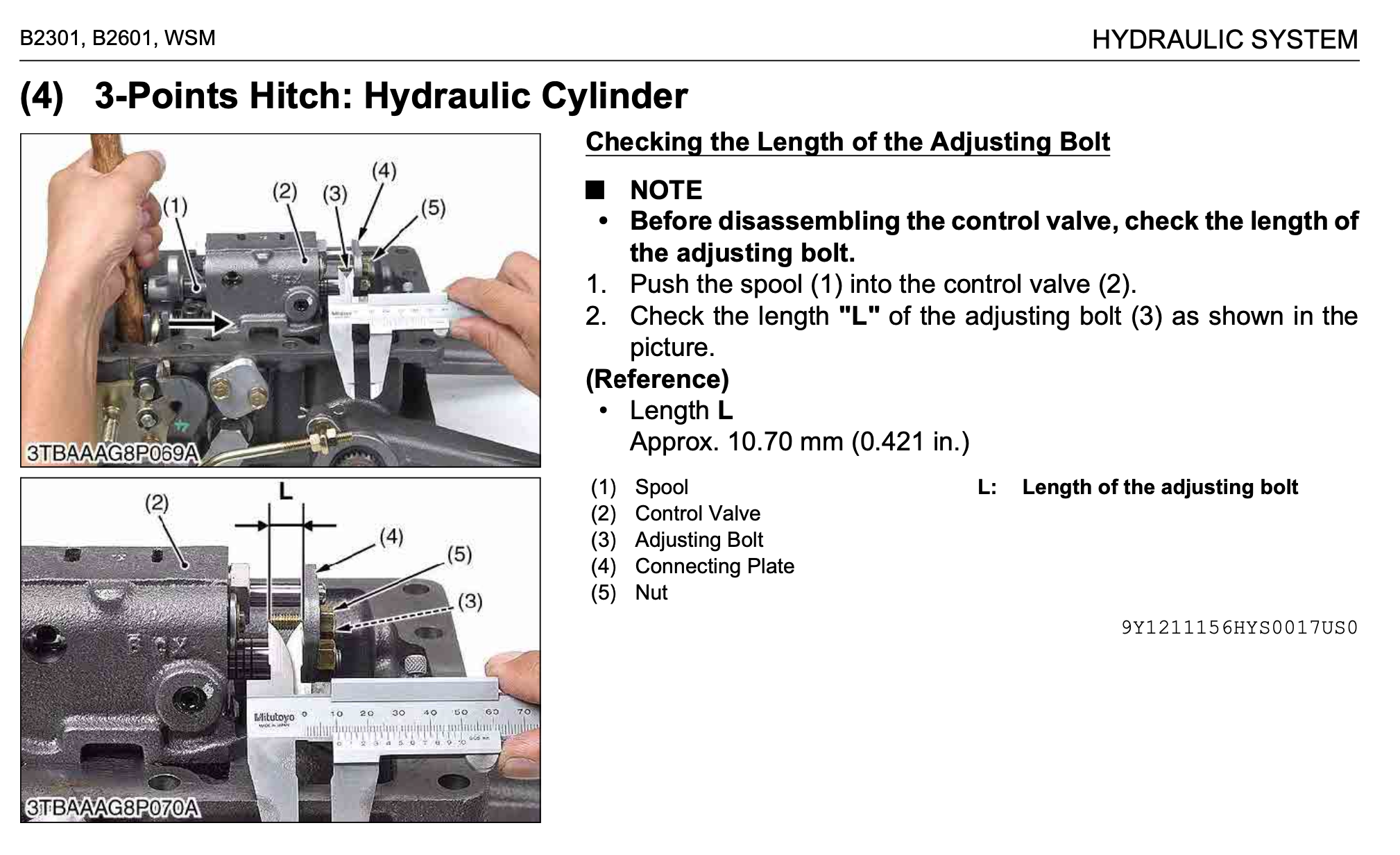

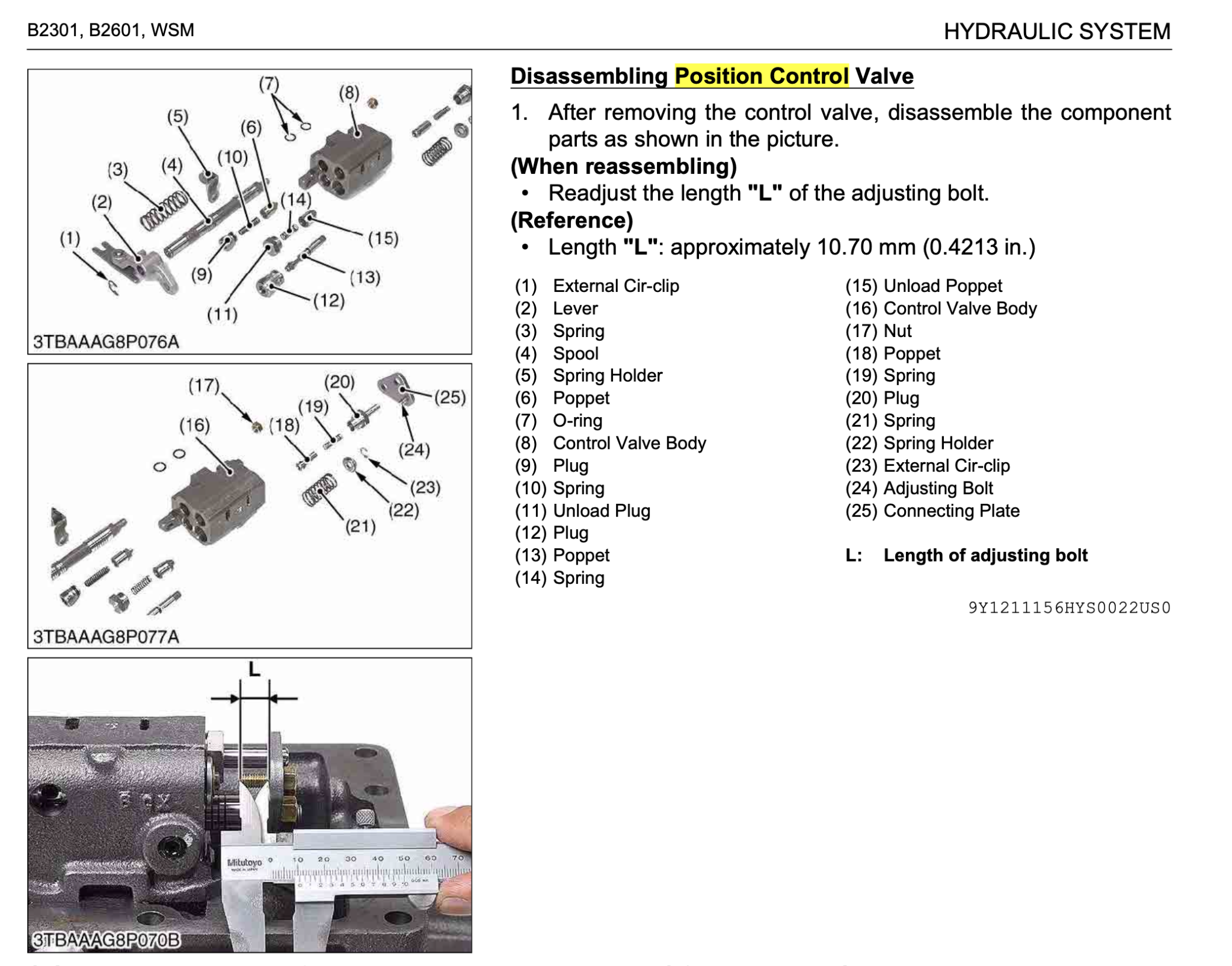

My WSM has this information, suggesting that I can adjust something by changing the length L of adjusting bolt 3:

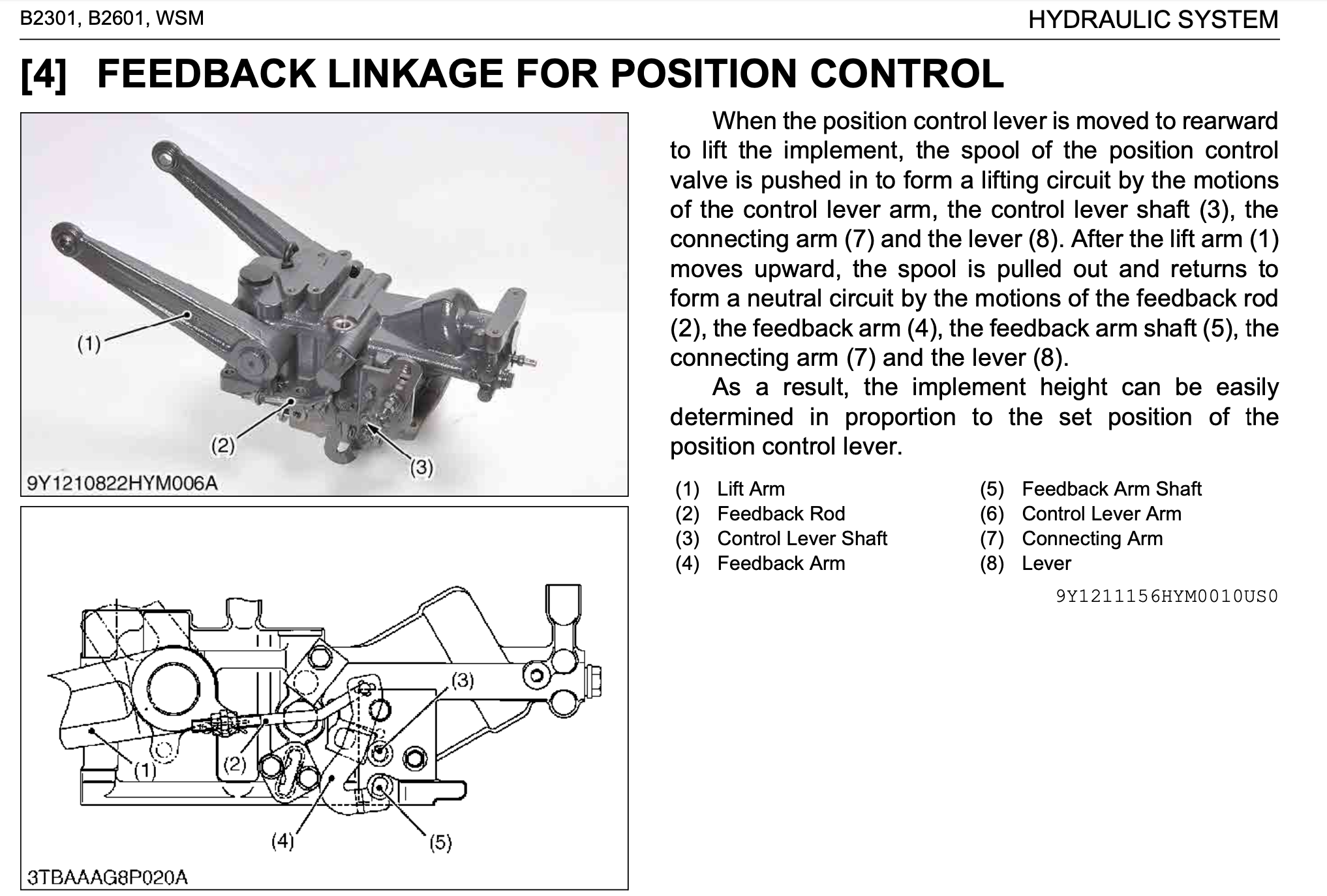

Has anyone tried this adjustment, or have any detail to add on how this works? It's night time at the moment, so I may have a play with it tomorrow. It isn't clear what exactly the adjusting bolt adjusts......but seems logical it would be the correlation between the feedback rod and the position control valve.

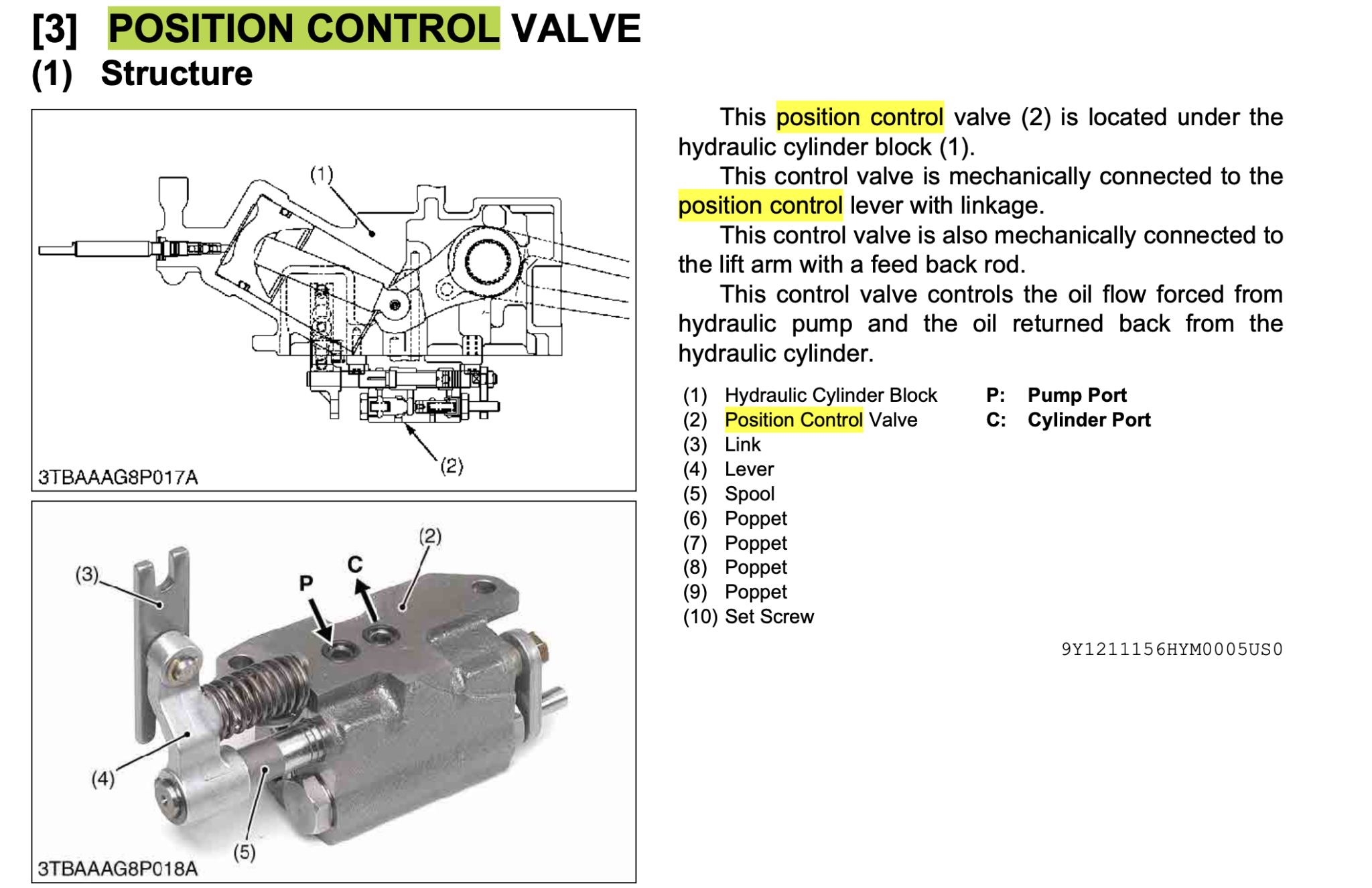

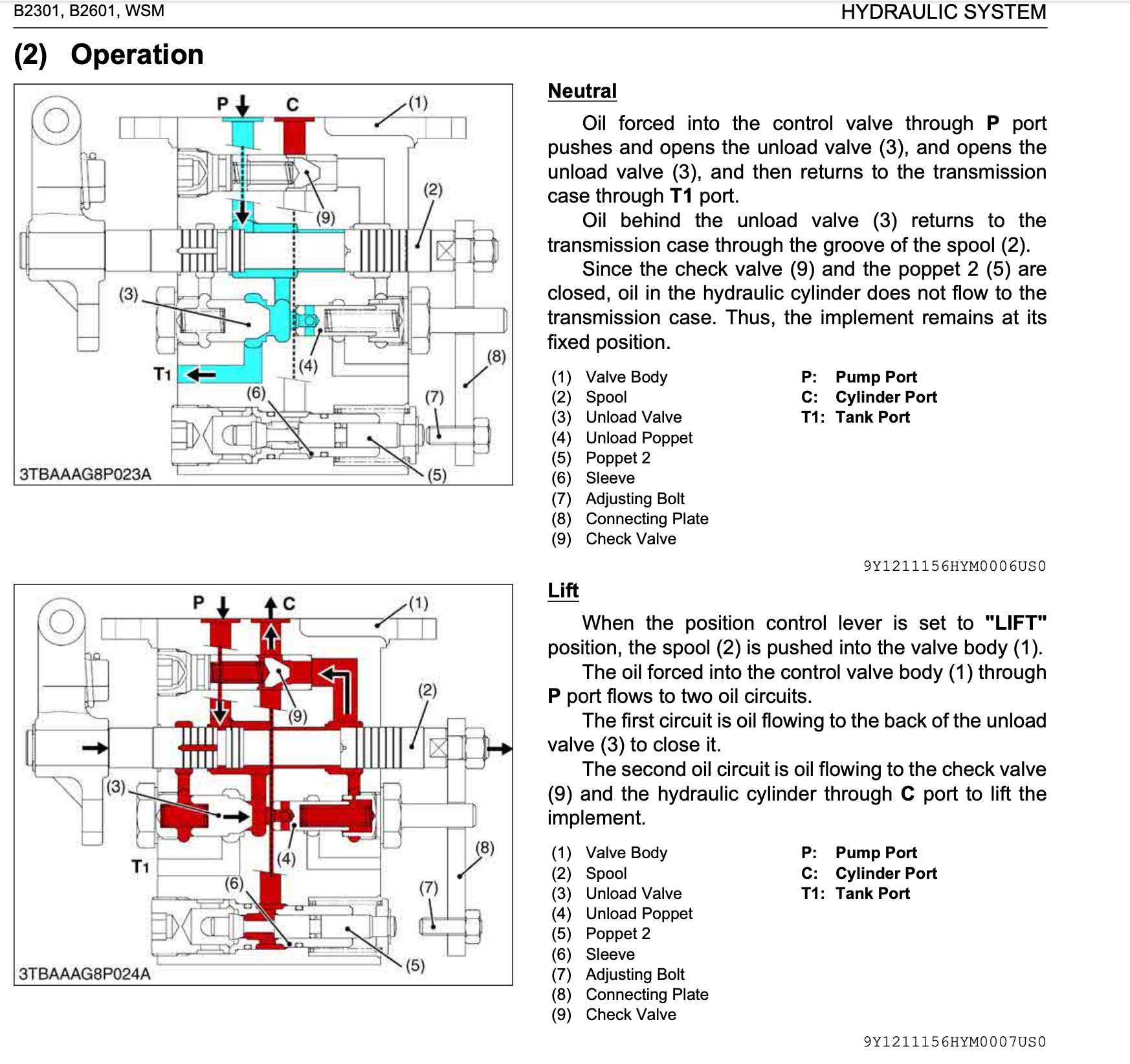

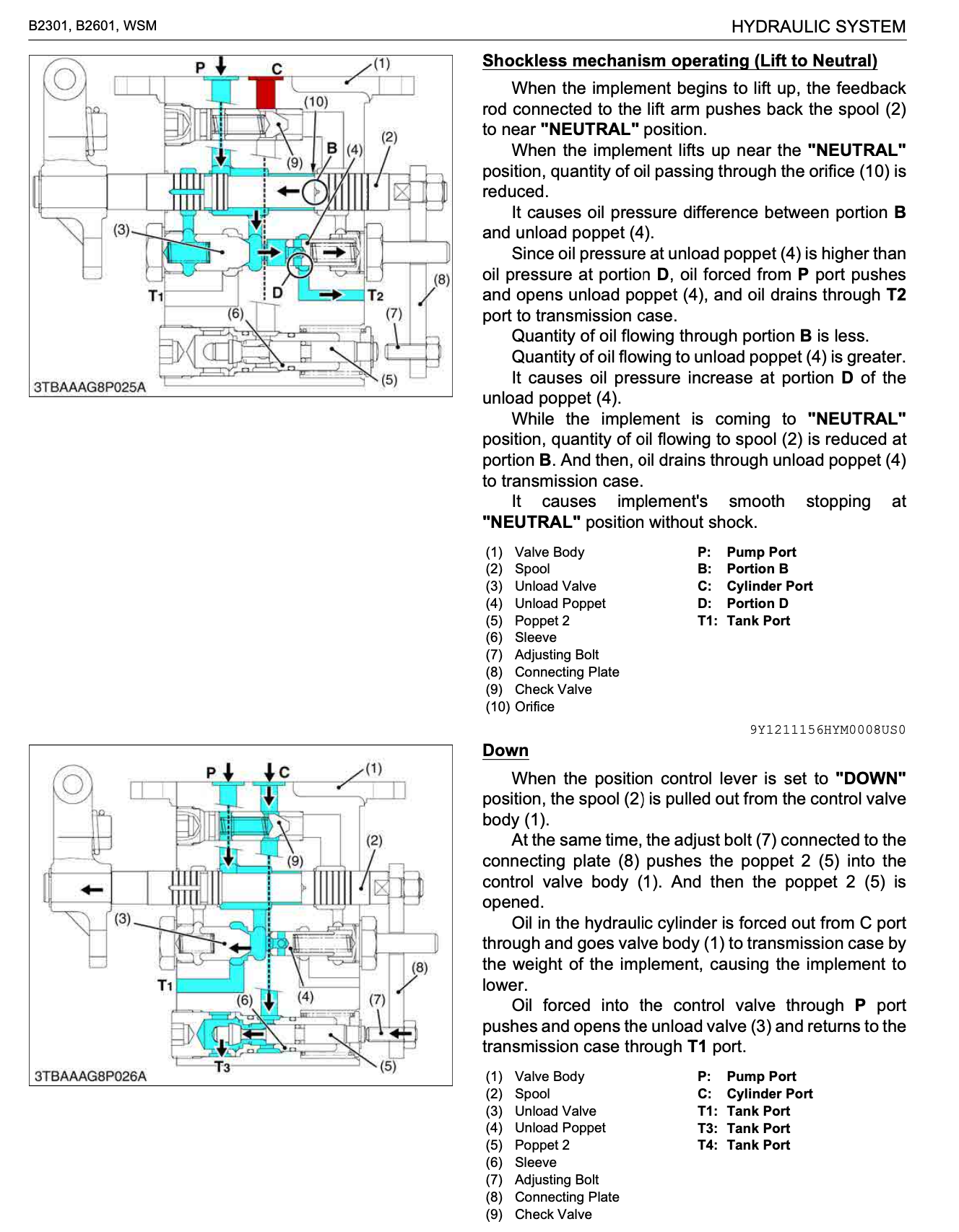

There's also a complex discussion of how exactly the position control works, and how it has a soft release as it reaches the neutral position. Copied here for entertainment purposes only, I don't understand other than vaguely, and I don't think it's relevant to the adjustment.

There's also a complex discussion of how exactly the position control works, and how it has a soft release as it reaches the neutral position. Copied here for entertainment purposes only, I don't understand other than vaguely, and I don't think it's relevant to the adjustment.

It is reaching the bottom of the 3ph range at position 4. The mower doesn't really start to lift till about 7. It only goes to 8. It doesn't seem to stop it working - I get full range of motion on the 3ph and on the mower. It just means I guess I get less fine control (and I don't really need fine control).

All of which is a way of saying this doesn't need fixing. But it annoys me.

My WSM has this information, suggesting that I can adjust something by changing the length L of adjusting bolt 3:

Has anyone tried this adjustment, or have any detail to add on how this works? It's night time at the moment, so I may have a play with it tomorrow. It isn't clear what exactly the adjusting bolt adjusts......but seems logical it would be the correlation between the feedback rod and the position control valve.