Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

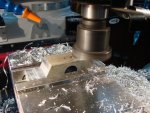

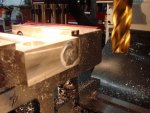

Today I had the day off so I decided to make a support for my hand when I'm using the welding positioner. When using these things the more steady your hand is the better the welding job is so this outfit that I got made will make life a little easier. It's not ground breaking but I made it our of left over aluminum I had around the shop and It gave me a chance to use the milling machine and the tig welder. Hard to believe it took all day to build it though

Attachments

-

83.6 KB Views: 456

-

89.5 KB Views: 467

-

90.5 KB Views: 457

-

69.5 KB Views: 431

-

90.8 KB Views: 447