I just finished what I believe and hope is the last upgraded alternator on my B3200. I believe this mod will work on other b series units as well but I'm not 100% sure.

This all started last year when I decided to add a cab for winter work. The cab came with a FREE 300W heater. Hot idea (pun intended). The problem is the little dynamo only puts out ~ 14 amps. Hmm 300W at 14V = 21A. We have a problem Houston

So, I researched here and elsewhere for solutions. I did find that Kubota had offered a 40A? alternator upgrade that was used on their cabbed models but they were no longer available. And being a tight a-- , I kept looking. I did find a thread on here that someone had done a 60A upgrade but could not locate a source for the suggested alternator.

OK, so I bought a couple of different units off amazon but could not get them to function properly using the charge lamp.

So, I resorted to my hot-rodding roots and found a 90A mini alternator that was a single wire hook up and added a small digital meter to monitor the V. A small amount of fabrication was required and we were jamming. I also upgraded the charging system wiring as needed.

I also upgraded the charging system wiring as needed.

So, then I get to thinking if I have all this power available why not add another heater?

I found an airplane cabin heater that puts out~ 650W. That should do it and the total draw is well under the 90A the alternator is rated at. So, I proceed to install the added heater, wiring, fuses etc. and all is well for about 3-4 hours. In the middle of summer with no real load on it the alternator dies. OK replace it under warranty. Second one same thing. A bit of googling shows the alternator was originally a 55A denso unit that is being copied by you know where and sold as a 90A.

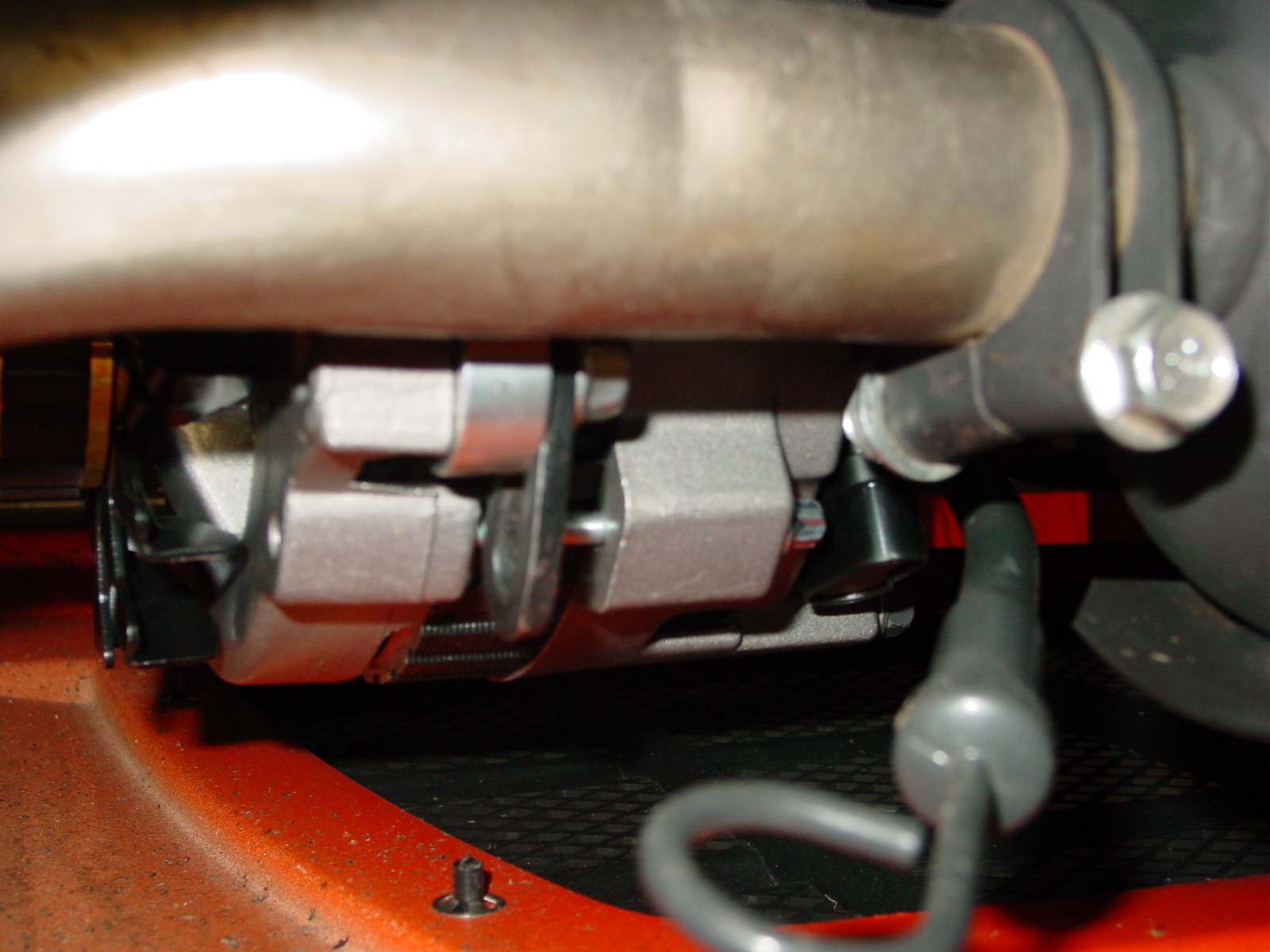

More research results in a GM CS121 alternator rated at 120A being sold by reputable sources. It appears bigger but actually fits better. Minor mod's again are required.

I am more confident than I was before as the unit is actually made here in the US and is a well-established company.

Sorry for the pic's as they were an afterthought. If anyone is interested, I can provide better pic's and more detail

Respond or send me a PM

This all started last year when I decided to add a cab for winter work. The cab came with a FREE 300W heater. Hot idea (pun intended). The problem is the little dynamo only puts out ~ 14 amps. Hmm 300W at 14V = 21A. We have a problem Houston

So, I researched here and elsewhere for solutions. I did find that Kubota had offered a 40A? alternator upgrade that was used on their cabbed models but they were no longer available. And being a tight a-- , I kept looking. I did find a thread on here that someone had done a 60A upgrade but could not locate a source for the suggested alternator.

OK, so I bought a couple of different units off amazon but could not get them to function properly using the charge lamp.

So, I resorted to my hot-rodding roots and found a 90A mini alternator that was a single wire hook up and added a small digital meter to monitor the V. A small amount of fabrication was required and we were jamming.

So, then I get to thinking if I have all this power available why not add another heater?

I found an airplane cabin heater that puts out~ 650W. That should do it and the total draw is well under the 90A the alternator is rated at. So, I proceed to install the added heater, wiring, fuses etc. and all is well for about 3-4 hours. In the middle of summer with no real load on it the alternator dies. OK replace it under warranty. Second one same thing. A bit of googling shows the alternator was originally a 55A denso unit that is being copied by you know where and sold as a 90A.

More research results in a GM CS121 alternator rated at 120A being sold by reputable sources. It appears bigger but actually fits better. Minor mod's again are required.

I am more confident than I was before as the unit is actually made here in the US and is a well-established company.

Sorry for the pic's as they were an afterthought. If anyone is interested, I can provide better pic's and more detail

Respond or send me a PM

Attachments

-

489.1 KB Views: 424

-

461.2 KB Views: 467