Hi all, I'm rebuilding my deck after the gearbox failed. It's taken me a while to get back to it, and while I'm pretty sure my old parts are well organised, I'm already stumbling.

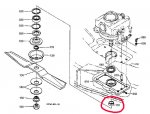

First problem is with the gearbox / centre spindle. I'm reusing a spacing collar (#170), that slips over the shaft between the upper oil seal and the bearing. In reassembling, I find that the bore of this collar is a couple of mm larger than the shaft (much more than just wear) - so it is apparently free to wobble around a couple of mm off centre if it so chooses. Does that seem right?! The new and old shafts match.

It isn't even apparent (to me) what purpose it serves. If anything it would seem to transfer any vertical forces from the gearbox to the inner race of the bearing. I'm not doubting Kubota's engineering but I would have thought this would be less desirable than allowing the shaft to slip within the inner race if such forces were occurring?

And what about the off-centred-ness? It's probably true that thick grease and centrifugal force would combine to keep it fairly well centred, but does this sound like Kubota design to you?!

First problem is with the gearbox / centre spindle. I'm reusing a spacing collar (#170), that slips over the shaft between the upper oil seal and the bearing. In reassembling, I find that the bore of this collar is a couple of mm larger than the shaft (much more than just wear) - so it is apparently free to wobble around a couple of mm off centre if it so chooses. Does that seem right?! The new and old shafts match.

It isn't even apparent (to me) what purpose it serves. If anything it would seem to transfer any vertical forces from the gearbox to the inner race of the bearing. I'm not doubting Kubota's engineering but I would have thought this would be less desirable than allowing the shaft to slip within the inner race if such forces were occurring?

And what about the off-centred-ness? It's probably true that thick grease and centrifugal force would combine to keep it fairly well centred, but does this sound like Kubota design to you?!

Attachments

-

56.8 KB Views: 958

Last edited: