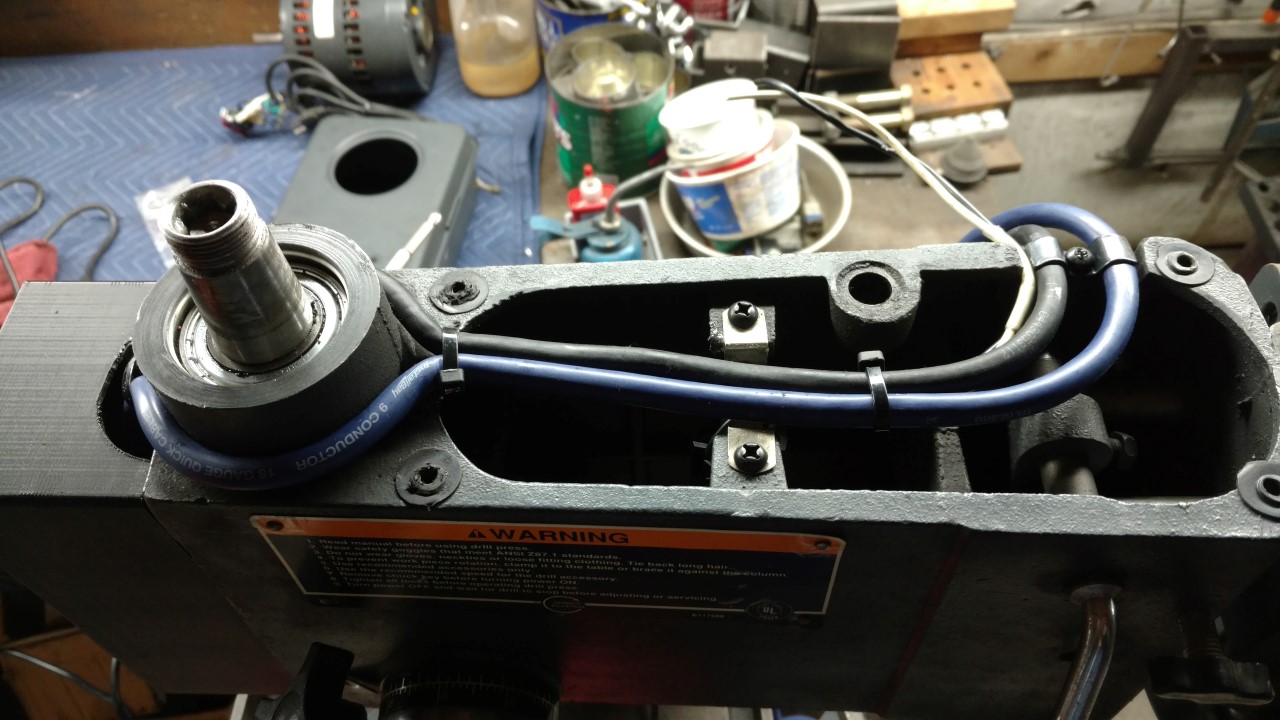

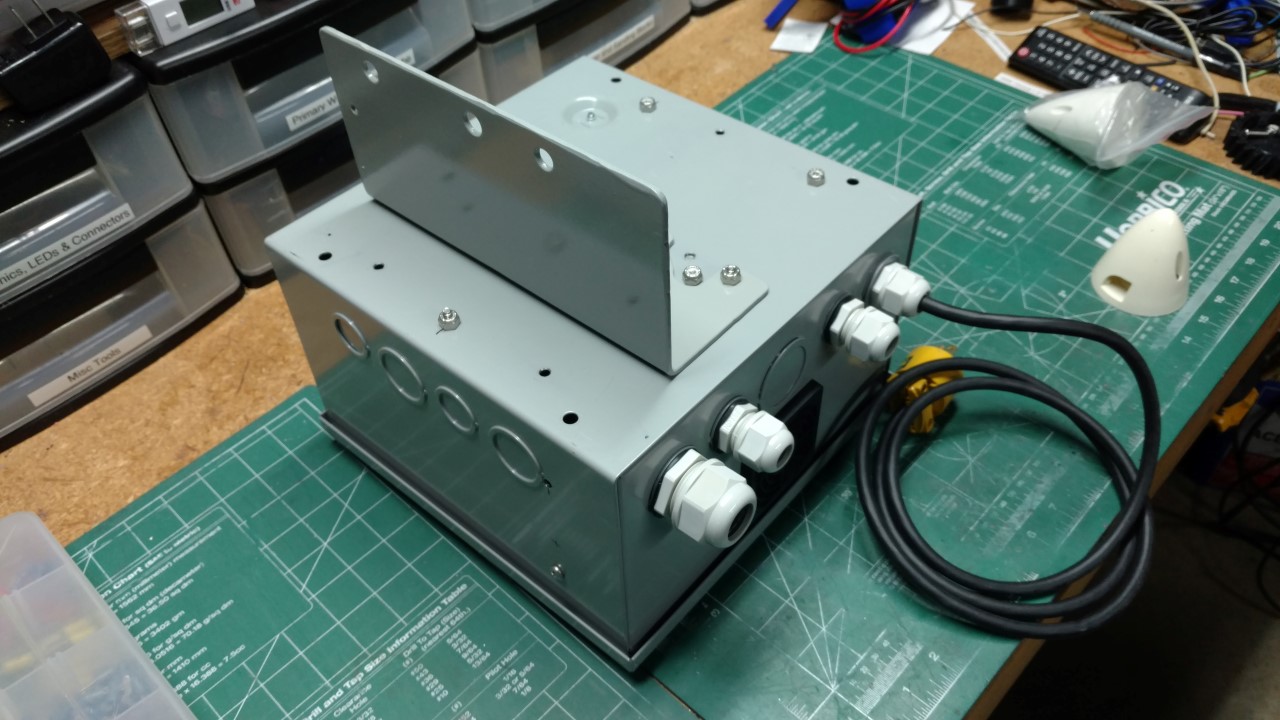

I have a Craftsman 17" 1.5 hp floor standing drill press I bought probably 15-20 years ago. It's been trouble free, but as I do a lot of different projects requiring drilling steel, aluminum, plastic and wood, changing the speeds by moving the belts around gets to be a pain in the derriere. So a while back I watched a YouTube video by Clough42 where he installed a new 3 phase motor and VFD on his Grizzly lathe, and it go me thinking. So I bought a TECO L510 single phase 115 VAC input VFD and a 1.0 hp 56 frame 3 phase motor to make the conversion. I made a new control panel and mounting box for the FWD/REV switch, ON/OFF switches, speed control potentiometer and a digital tach display. I bought a 10" X 10" X 6" case with a hinged cover to mount everything in. It's a tight fit and there's no room to really route the wires as neatly as I would like, but it works. I installed the tach pickup in the lower belt housing and glued the magnet to the spindle pulley. I had to make a mounting bracket for the box, so I used a piece if 1/8" plate out of my scrap bin and bent it 90° so I could bolt it to the motor mount and the back of the box. I got everything mounted in the case, twice. I had to switch the VFD to the opposite side as the door latch hit it and the cover wouldn't close. So after drilling more holes, I got everything mounted and wired up everything I could until I mounted it on the drill press.

I took it down that afternoon and got the case mounted, ran the four cables into the box, stripped outer insulation off all them and cut the individual wiresl to the correct length and connected them to the proper terminals. I double checked all the connections and everything was connected correctly, so I plugged the power cord in, tripped on the circuit breaker. No sparks, fire or bangs, so I checked for voltage st the contactor and it was good. Pushed the on button and the VFD powered up, the ON/OFF buttons lit up and the tach digital display came on and read zero. I turned the switch to forward and the drill started rotating a about 140 rpm and sped up when the knob was turned clockwise. Switching from forward to reverse, the spindle slowed down, stopped and then reversed as per the parameters I set up in the VFD.

A safety setting I also enabled was to disable the drive if turned on with the speed control is not at minimum. You must set the control to minimum speed and power cycle the drive before it will power up the motor.

The only problem I had was that the tach wouldn't work. Wasn't sure why. I mounted the pickup the specified distance from the magnet on the pulley, but I can see the cable end of the pickup and the LED is lit.

I isolated the tach problem to the sensor. Sooooo, I installed a connector on a new sensor, connected it, stuck a magnet on the drill chuck, turned it on and brought the spindle speed up while holding the sensor next to it, and the display read out the proper RPMs.

It seems that the magnet that comes with the tach kit has to have a certain side facing the sensor. When I held the new sensor next to the magnet on the pulley, it wouldn't work either. Hmmmm. So I tried the new magnet by sticking it on the chuck and running it and with one side facing the sensor it worked, and when flipped over it wouldn't. That is very strange. I pulled the pulley off, popped the magnet off and hot glued it on with the other side facing the sensor. Put it all back together and it works like it should.

The instructions with the kit don't mention that a certain side, or pole must be facing the sensor.

Drilled a couple of test holes with 3/8" and 1/2" bits in 1/4" material, and it works great. When running at about 300 rpm, it only drops 10-20 rpm when drilling with normal pressure.

I think it will be a great upgrade, as the drill press is one of my most used tools in the shop.

I took it down that afternoon and got the case mounted, ran the four cables into the box, stripped outer insulation off all them and cut the individual wiresl to the correct length and connected them to the proper terminals. I double checked all the connections and everything was connected correctly, so I plugged the power cord in, tripped on the circuit breaker. No sparks, fire or bangs, so I checked for voltage st the contactor and it was good. Pushed the on button and the VFD powered up, the ON/OFF buttons lit up and the tach digital display came on and read zero. I turned the switch to forward and the drill started rotating a about 140 rpm and sped up when the knob was turned clockwise. Switching from forward to reverse, the spindle slowed down, stopped and then reversed as per the parameters I set up in the VFD.

A safety setting I also enabled was to disable the drive if turned on with the speed control is not at minimum. You must set the control to minimum speed and power cycle the drive before it will power up the motor.

The only problem I had was that the tach wouldn't work. Wasn't sure why. I mounted the pickup the specified distance from the magnet on the pulley, but I can see the cable end of the pickup and the LED is lit.

I isolated the tach problem to the sensor. Sooooo, I installed a connector on a new sensor, connected it, stuck a magnet on the drill chuck, turned it on and brought the spindle speed up while holding the sensor next to it, and the display read out the proper RPMs.

It seems that the magnet that comes with the tach kit has to have a certain side facing the sensor. When I held the new sensor next to the magnet on the pulley, it wouldn't work either. Hmmmm. So I tried the new magnet by sticking it on the chuck and running it and with one side facing the sensor it worked, and when flipped over it wouldn't. That is very strange. I pulled the pulley off, popped the magnet off and hot glued it on with the other side facing the sensor. Put it all back together and it works like it should.

The instructions with the kit don't mention that a certain side, or pole must be facing the sensor.

Drilled a couple of test holes with 3/8" and 1/2" bits in 1/4" material, and it works great. When running at about 300 rpm, it only drops 10-20 rpm when drilling with normal pressure.

I think it will be a great upgrade, as the drill press is one of my most used tools in the shop.

Last edited: