Hi, I'm finding the clutch on my B4200 to be so sharp, it's almost like a switch, either in or out. It makes pulling away in the high range pretty tricky. My thoughts are that the cushion springs in the centre plate are shot??

Clutch operation

- Thread starter Citro-nut

- Start date

The springs in the clutch disk are installed to deal with other issues as you will read below.Hi, I'm finding the clutch on my B4200 to be so sharp, it's almost like a switch, either in or out. It makes pulling away in the high range pretty tricky. My thoughts are that the cushion springs in the centre plate are shot??

What is the history of your tractor and its clutch?

Causes of harsh clutch action:

Worn out pilot bearing or bushing.

Oil or grease contamination on the disk or flywheel from a leaking seal or over greasing when a new clutch disk was installed resulting in grease thrown unto the clutch surfaces.

Dave.

Hi Dave, thanks for your reply. I have no history of the tractor, however it is exceptionally clean and freshly painted ( brushed, I'll be redoing that properly at some point!! ) so I don't know if there are any oil leaks as yet. I was drawing on my 40+ years as a motor mechanic when considering the issues including the causes you mentioned, certainly directly related to the clutch assy. However, I've no knowledge of tractors as yet so I was wondering ( hoping ) if there was anything specific to tractors which could result in these symptoms.

If not then I suppose I'll have to bite the bullet and strip it down in the autumn. That's a job which looks worse that it is I hope??!!

Regards Trevor

If not then I suppose I'll have to bite the bullet and strip it down in the autumn. That's a job which looks worse that it is I hope??!!

Regards Trevor

Trevor

The big difference between tractors like yours and big trucks is that these tractors have no synchro's and double clutching is generally not possible because the momentum is low and speed drop between gear changes is too great. You pick your gear and start in that gear.

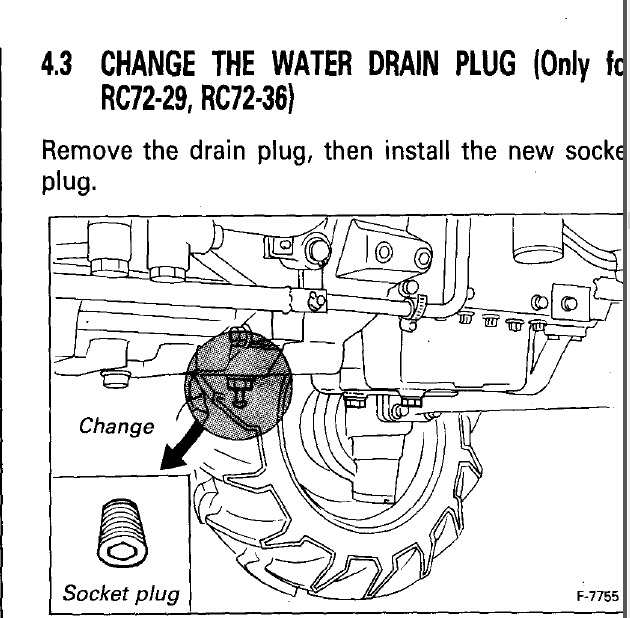

Look for any inspection port on the bell housing. If there is one you might get a glimpse of the internals and see if excess oil/greasae has been flung around,.

Some tractors have a drain under the clutch. A small button you depress to let any fluid accumulation out. Water usually indicates a torn shifter boot. Oil a leaking crank or transmission seal.

If you are going to split the tractor then as a last step before, try burnishing the clutch. A fancy term usually applied to brakes

Get the tractor where it cannot move... a large tree etc and drag the clutch as it tries to move the tractor. It will get hot and smell. Do not over do it but this may burn off contaminants causing the harsh action.

A prior owner cleaning the machine with a pressure washer prior to a brush paint job can hide many problems from a purchaser.

Dave

The big difference between tractors like yours and big trucks is that these tractors have no synchro's and double clutching is generally not possible because the momentum is low and speed drop between gear changes is too great. You pick your gear and start in that gear.

Look for any inspection port on the bell housing. If there is one you might get a glimpse of the internals and see if excess oil/greasae has been flung around,.

Some tractors have a drain under the clutch. A small button you depress to let any fluid accumulation out. Water usually indicates a torn shifter boot. Oil a leaking crank or transmission seal.

If you are going to split the tractor then as a last step before, try burnishing the clutch. A fancy term usually applied to brakes

Get the tractor where it cannot move... a large tree etc and drag the clutch as it tries to move the tractor. It will get hot and smell. Do not over do it but this may burn off contaminants causing the harsh action.

A prior owner cleaning the machine with a pressure washer prior to a brush paint job can hide many problems from a purchaser.

Dave

Last edited:

Trevor

Sometimes when I give owners the EATON documents on clutch disks not everyone is convinced that the springs are for torsional vibration.

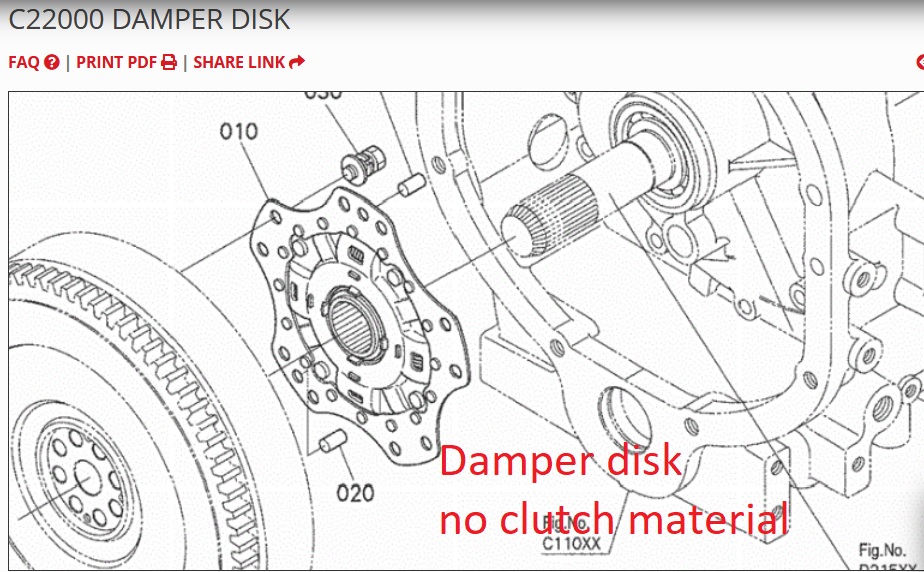

I came across this parts illustration for a M7040 with hydraulic shuttle. This tractor does not have a clutch disk in the traditional sense and uses the shuttle clutch packs like in an automatic transmission as the "clutch".

What is maintained in a DAMPER DISK. You will note it has the same design as a dry clutch disk with the springs but no friction material.

Dave

Sometimes when I give owners the EATON documents on clutch disks not everyone is convinced that the springs are for torsional vibration.

I came across this parts illustration for a M7040 with hydraulic shuttle. This tractor does not have a clutch disk in the traditional sense and uses the shuttle clutch packs like in an automatic transmission as the "clutch".

What is maintained in a DAMPER DISK. You will note it has the same design as a dry clutch disk with the springs but no friction material.

Dave

Hi Dave. Yes I agree that the springs are there primarily for the purpose of vibration damping, they do also cushion the take up to a degree.

The dampening effect is similar in a way to the modern car with a 'Dual mass flywheel'. In principle it gives a smoother low load effect on the engine/ transmission operation. In practice after a while it throws up so many other running issues that I know of taxi companies having replaced them with solid flywheels and clutches, then they knock out gearboxes on a regular basis!!

The illustration above is interesting, not something I've seen before.

Regards, Trevor.

The dampening effect is similar in a way to the modern car with a 'Dual mass flywheel'. In principle it gives a smoother low load effect on the engine/ transmission operation. In practice after a while it throws up so many other running issues that I know of taxi companies having replaced them with solid flywheels and clutches, then they knock out gearboxes on a regular basis!!

The illustration above is interesting, not something I've seen before.

Regards, Trevor.