hi all,

i have some loader design questions for my b7000. you guys already provided me some good info on the subframe so i i picked up a rough condition unknown brand loader locally that surprisingly seems to fit pretty closely. however, it comes with no pump and a remote reservoir tank that is way too big to hang off the loader tower (which also does not have room inside it for a tank).

i would prefer a front pump factory style but it looks like after reading threads here that a rear pto may be the more realistic option.

my questions

1. front pump option: just to confirm is it still impossible to source a female 25mm x 18t sleeve to hookup a coupler to the front driveshaft spline for a factory style front mounted pump? i have found some older threads here suggesting there was no source at that time for these and that i will need to have a flange fabricated to bolt to the fanbelt pulley if i go this route.

2. front pump option: is there a source for a reasonable cost shaft mount electro-mechanical coupler at the pump if i front mount a pump? no way do i want the pump always on.

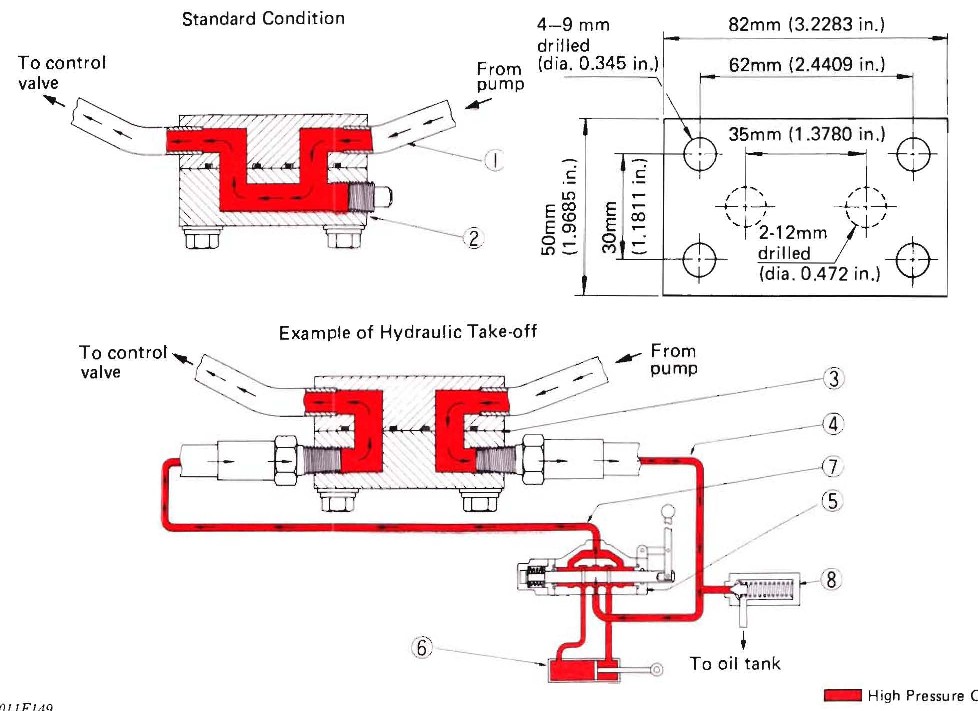

3. factory hydraulic option: does anyone know the flow gpm of the factory hydraulics if i went that route? i am thinking pretty minimal. also, am i correct that the factory diverter block to do this is not available now and i would need to machine the existing block?

4. front or rear pump option: has anyone come up with a clever location for a remote reservoir tank on a b6000/7000/7100? there is no room for a tower tank in this loader and the tank it came with is too large.

i am currently leaning towards a rear pto pump set up and some kind of tray mounted to the three point for the reservoir tank that could rest on top of another implement. i have an old 50 gallon square spray tank i will use as a ballast tank but i also want to be able to use the loader with my box blade on the back.

i have some loader design questions for my b7000. you guys already provided me some good info on the subframe so i i picked up a rough condition unknown brand loader locally that surprisingly seems to fit pretty closely. however, it comes with no pump and a remote reservoir tank that is way too big to hang off the loader tower (which also does not have room inside it for a tank).

i would prefer a front pump factory style but it looks like after reading threads here that a rear pto may be the more realistic option.

my questions

1. front pump option: just to confirm is it still impossible to source a female 25mm x 18t sleeve to hookup a coupler to the front driveshaft spline for a factory style front mounted pump? i have found some older threads here suggesting there was no source at that time for these and that i will need to have a flange fabricated to bolt to the fanbelt pulley if i go this route.

2. front pump option: is there a source for a reasonable cost shaft mount electro-mechanical coupler at the pump if i front mount a pump? no way do i want the pump always on.

3. factory hydraulic option: does anyone know the flow gpm of the factory hydraulics if i went that route? i am thinking pretty minimal. also, am i correct that the factory diverter block to do this is not available now and i would need to machine the existing block?

4. front or rear pump option: has anyone come up with a clever location for a remote reservoir tank on a b6000/7000/7100? there is no room for a tower tank in this loader and the tank it came with is too large.

i am currently leaning towards a rear pto pump set up and some kind of tray mounted to the three point for the reservoir tank that could rest on top of another implement. i have an old 50 gallon square spray tank i will use as a ballast tank but i also want to be able to use the loader with my box blade on the back.

Attachments

-

660.1 KB Views: 132