I am sorry to have to ask this question but last summer I purchased a Kubota B2782B snowblower to go on my B3200 tractor. The snowblower itself doesn’t seem to be in bad shape but I could tell by looking around the garage where it was at the previous owner wasn’t a fan of scheduled maintenance. I bought the proper subframe new from a dealer so I know that component is complete. Before hooking it up and engaging the PTO driveline I pulled off the inspection plate to look at the chain and sprockets. There I found about an inch of slack in the chain and a tooth missing on the reduction sprocket  . I have purchased a new chain, sprocket and bearings to go on the reduction shaft. Maybe I didn't need to replace the chain and bearings but I am already all the way in here and bearings were not that much. But on further examination I see on the manuals exploded diagram a pair of adjustment plates which I didn’t see when I removed the reduction box. I am going to purchase these adjustments plates but can someone tell me exactly where they go as it doesn’t really show where they are placed in the exploded diagram? The gearbox seems to be fine with no play, auger bearings seem fine, augers move freely with shear pins removed, no play in fan bearings and it moves freely. So I think I dodged a bullet by replacing the sprocket and chain before everything blew up. If someone can tell the placement of the adjustment plates I would be very grateful. Also if I am missing something feel free to comment I would appreciate it.

. I have purchased a new chain, sprocket and bearings to go on the reduction shaft. Maybe I didn't need to replace the chain and bearings but I am already all the way in here and bearings were not that much. But on further examination I see on the manuals exploded diagram a pair of adjustment plates which I didn’t see when I removed the reduction box. I am going to purchase these adjustments plates but can someone tell me exactly where they go as it doesn’t really show where they are placed in the exploded diagram? The gearbox seems to be fine with no play, auger bearings seem fine, augers move freely with shear pins removed, no play in fan bearings and it moves freely. So I think I dodged a bullet by replacing the sprocket and chain before everything blew up. If someone can tell the placement of the adjustment plates I would be very grateful. Also if I am missing something feel free to comment I would appreciate it.

B2782B Snowblower Purchased - Adjustment Plates?

- Thread starter JIMMI

- Start date

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

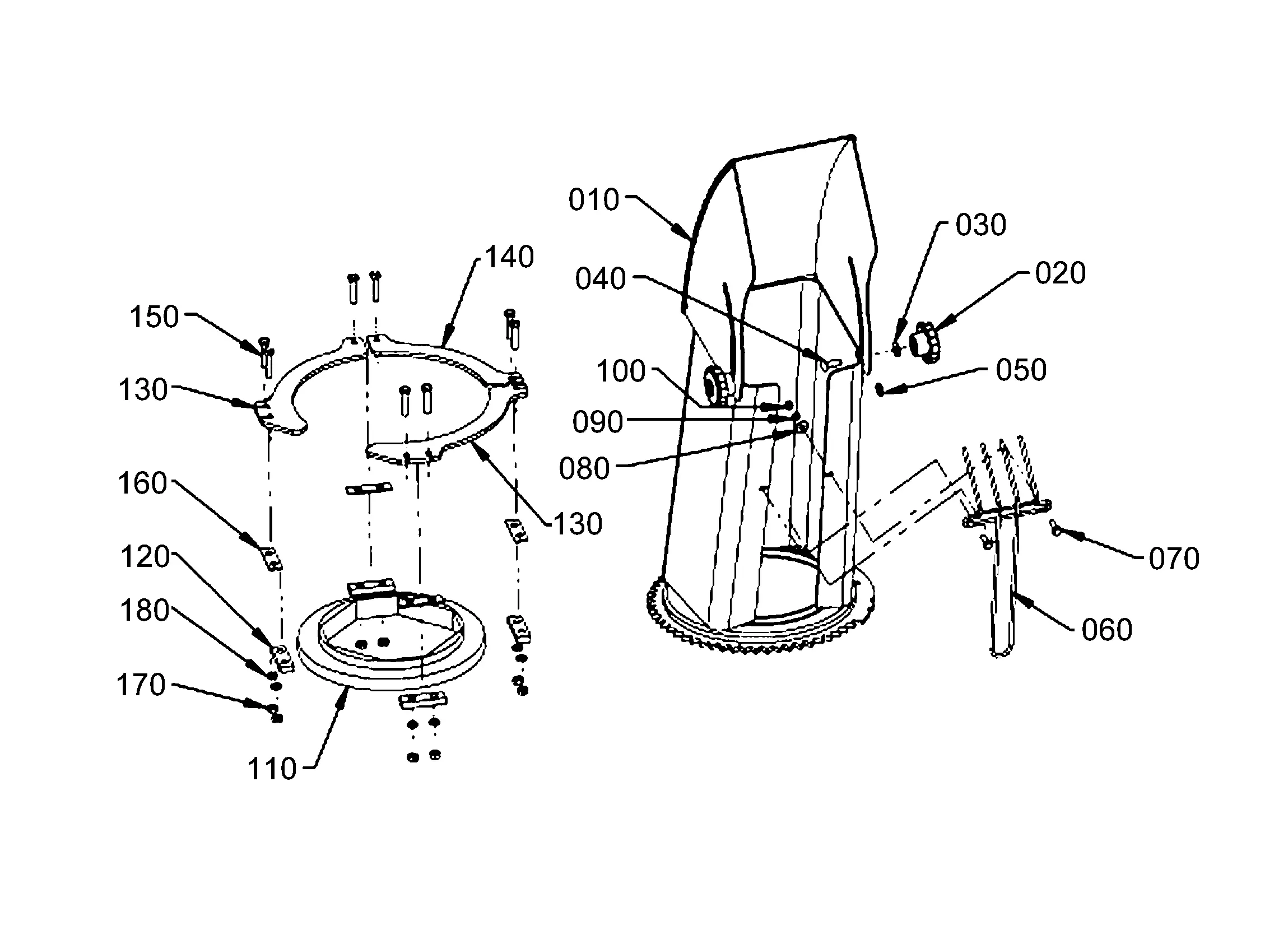

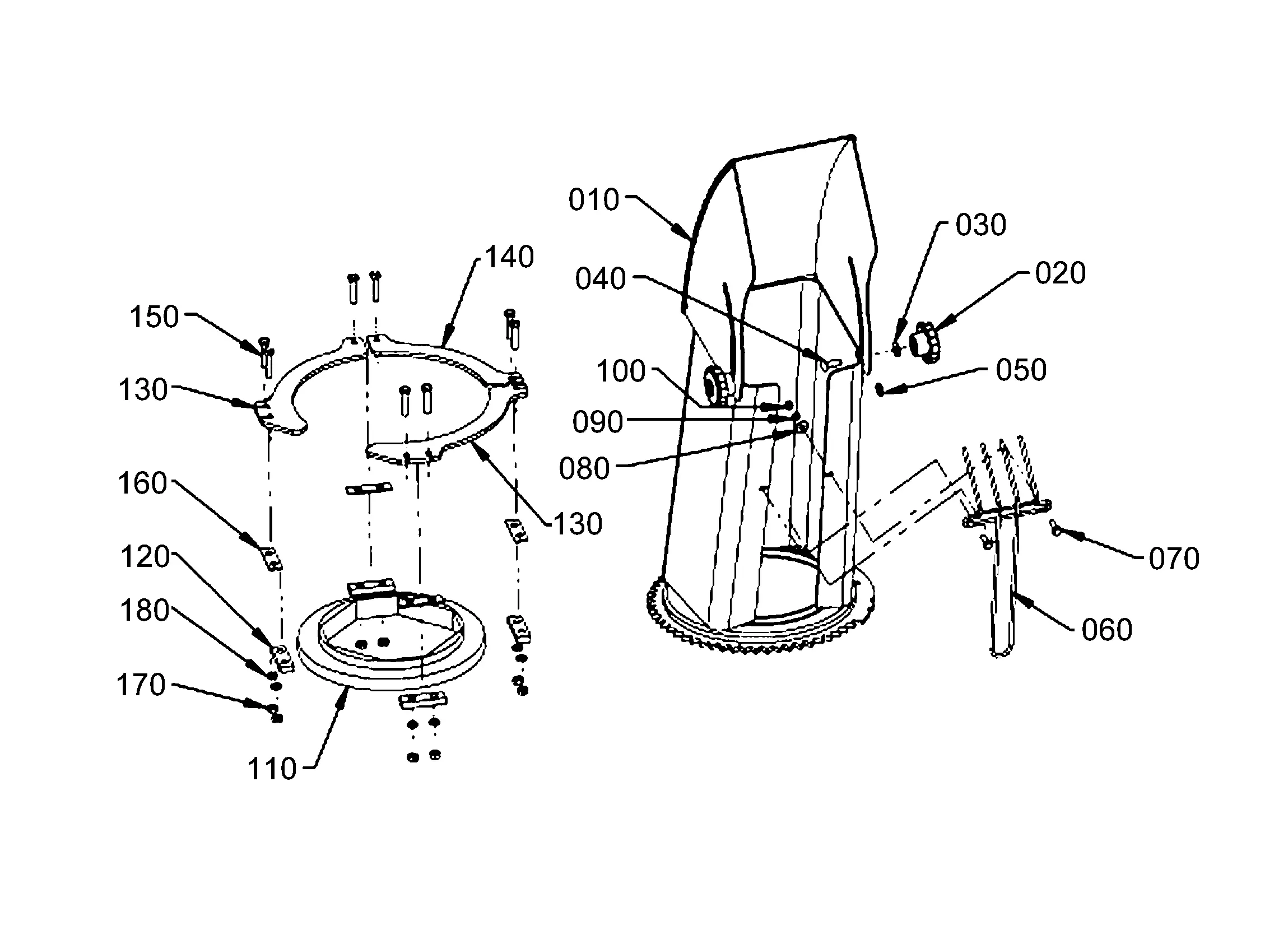

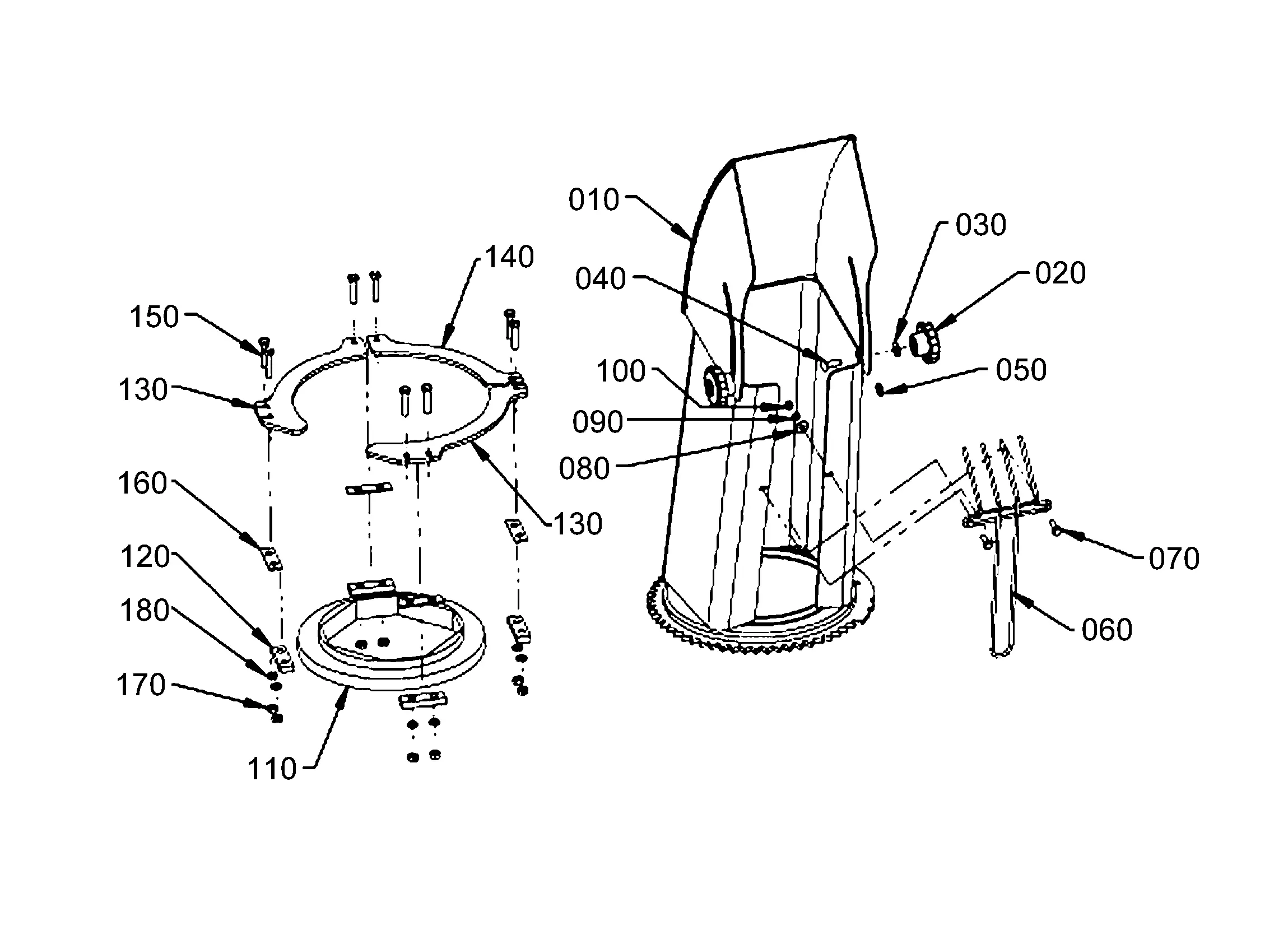

From the illustrated parts list shown below, the adjustment plates are shown in yellow. I assume that they would be installed between the green and blue surfaces (highlighted below) to remove slack in the chain.

Rcflyer330

Active member

Equipment

Kubota B2650 Cab, B2779 Broom, B2782B Snowblower, RB1672 rear blade

Something is not right. You have a B2782B blower correct? Because the kubota part diagram the B2782A snowblower has thoes plates the B2782B does not. Also thoes adjustment plates look to be holding the nut from turning on the b2782a blower.

I have a b2782b snowblower that I had to rebuild the reduction gearbox on earlier this year. Had it completly apart and there was no plate like that on my blower. Here is a tip maybe you know already maybe not. The bearings on the reduction shaft may be a cam lock style with no set screw. Thease bearings lock in the same direction that the shaft spins. I didn't know this when I was tearing it down. Also a pin hook spanner wrench really helps with the cam style locks.

I have a b2782b snowblower that I had to rebuild the reduction gearbox on earlier this year. Had it completly apart and there was no plate like that on my blower. Here is a tip maybe you know already maybe not. The bearings on the reduction shaft may be a cam lock style with no set screw. Thease bearings lock in the same direction that the shaft spins. I didn't know this when I was tearing it down. Also a pin hook spanner wrench really helps with the cam style locks.

Last edited:

BAP

Well-known member

Lifetime Member

Equipment

2012 Kubota 2920, 60MMM, FEL, BH65 48" Bush Hog, 60"Backblade, B2782B Snowblower

This is the correct parts page for the B2782B snowblower.

Kubota B2781B B2782B SN 21503940 AND UP Parts Diagrams

Kubota Parts Catalog Lookup. Buy Kubota Parts Online & Save!

www.messicks.com

Something is not right. You have a B2782B blower correct? Because the kubota part diagram the B2782A snowblower has thoes plates the B2782B does not. Also thoes adjustment plates look to be holding the nut from turning on the b2782a blower.

I have a b2782b snowblower that I had to rebuild the reduction gearbox on earlier this year. Had it completly apart and there was no plate like that on my blower. Here is a tip maybe you know already maybe not. The bearings on the reduction shaft may be a cam lock style with no set screw. Thease bearings lock in the same direction that the shaft spins. I didn't know this when I was tearing it down. Also a pin hook spanner wrench really helps with the cam style locks.

Thank You Very Much - No I didn’t know the

Thanks to all of you for your help. You have cleared everything up for me. I just wanted to make sure that when I put this all back together I was putting it back together as it came originally. I didn’t see any plates when I dissembled the reduction box And I thought maybe someone had taken it apart before and didn’t feel the need reinstall them. I also appreciate the reference to the correct schematic for the B2782B blower. Also I didn’t know about the bearings being a cam lock style lock. Thanks again for that update. I will post again after I get this all back together.This is the correct parts page for the B2782B snowblower.

Kubota B2781B B2782B SN 21503940 AND UP Parts Diagrams

Kubota Parts Catalog Lookup. Buy Kubota Parts Online & Save!www.messicks.com

View attachment 166941

nbryan

Well-known member

Equipment

B2650 BH77 LA534 54" ssqa Forks B2782B BB1560 Woods M5-4 MaxxHaul 50039

I have the same blower that's run 8 winters now, and a couple of things to watch for:

- the PTO input shaft #040 in BAP's diagram supports a series of mechanical connections that get hammered running at 2500rpm driving the reduction chain. ALL the setscrews on mine needed tightening, and the input pto shaft #070 key even fell out while in use. Use threadlock and tighten to max safe torque all the setscrews for locking the keys, sprocket, and bearings to that shaft. Then check for any play regularly and re-torque setscrews every service.

- My reduction chain tension proved tricky to adjust, and set it too tight at first, proving quite noisy. Turns out a slight off-centeredness of the large gear allows the play to vary as it rotates. Rotate it completely several times to find the tightest point in the chain play, and adjust it there.

- the PTO input shaft #040 in BAP's diagram supports a series of mechanical connections that get hammered running at 2500rpm driving the reduction chain. ALL the setscrews on mine needed tightening, and the input pto shaft #070 key even fell out while in use. Use threadlock and tighten to max safe torque all the setscrews for locking the keys, sprocket, and bearings to that shaft. Then check for any play regularly and re-torque setscrews every service.

- My reduction chain tension proved tricky to adjust, and set it too tight at first, proving quite noisy. Turns out a slight off-centeredness of the large gear allows the play to vary as it rotates. Rotate it completely several times to find the tightest point in the chain play, and adjust it there.

So how frequently do you actually recheck set screws on the bearings and sprockets ? It looks like I can check the chain tension easily but it would take a lot more time and effort to check the set screws on the bearings and sprocket.I have the same blower that's run 8 winters now, and a couple of things to watch for:

- the PTO input shaft #040 in BAP's diagram supports a series of mechanical connections that get hammered running at 2500rpm driving the reduction chain. ALL the setscrews on mine needed tightening, and the input pto shaft #070 key even fell out while in use. Use threadlock and tighten to max safe torque all the setscrews for locking the keys, sprocket, and bearings to that shaft. Then check for any play regularly and re-torque setscrews every service.

- My reduction chain tension proved tricky to adjust, and set it too tight at first, proving quite noisy. Turns out a slight off-centeredness of the large gear allows the play to vary as it rotates. Rotate it completely several times to find the tightest point in the chain play, and adjust it there.

nbryan

Well-known member

Equipment

B2650 BH77 LA534 54" ssqa Forks B2782B BB1560 Woods M5-4 MaxxHaul 50039

What I do is look for any play between the shaft and the pto input and the small reduction gear.

I push a small screwdriver through a small opening that the small gear and chain can be seen through, and hold the sprocket/chain still while twisting back and forth the intput PTO u-joint and feeling for, or seeing, looseness between that pto input and the chain drive sprocket itself. Click - click, or wobble - wobble, and the chain access cover comes off for further investigation.

If no play can be felt or seen, it should be good to go.

I use socket set extensions to reach inside the case to tighten down any loose setscrews. Using a 1/2" socket drive with hex drive tip also allows for upping the tightening torque some, and it seems the screws can take quite a bit of tightening torque. All efforts tightening with regular hex (allen key) drivers didn't hold.

They've finally stopped loosening for a few seasons now. Super-tightening the screws is a butt-clencher, as the last thing needed is stripping them, but they're pretty tough.

I push a small screwdriver through a small opening that the small gear and chain can be seen through, and hold the sprocket/chain still while twisting back and forth the intput PTO u-joint and feeling for, or seeing, looseness between that pto input and the chain drive sprocket itself. Click - click, or wobble - wobble, and the chain access cover comes off for further investigation.

If no play can be felt or seen, it should be good to go.

I use socket set extensions to reach inside the case to tighten down any loose setscrews. Using a 1/2" socket drive with hex drive tip also allows for upping the tightening torque some, and it seems the screws can take quite a bit of tightening torque. All efforts tightening with regular hex (allen key) drivers didn't hold.

They've finally stopped loosening for a few seasons now. Super-tightening the screws is a butt-clencher, as the last thing needed is stripping them, but they're pretty tough.