L295DT

youtube.com

youtube.com

This is a video of hole in the block

Ok here's a picture of the hole in the block

I was running L295DT leveling land, when engine exploded, spilled oil all over the ground etc.

Ok here's a parts tractor that has a good block/other parts that are needed for the fix

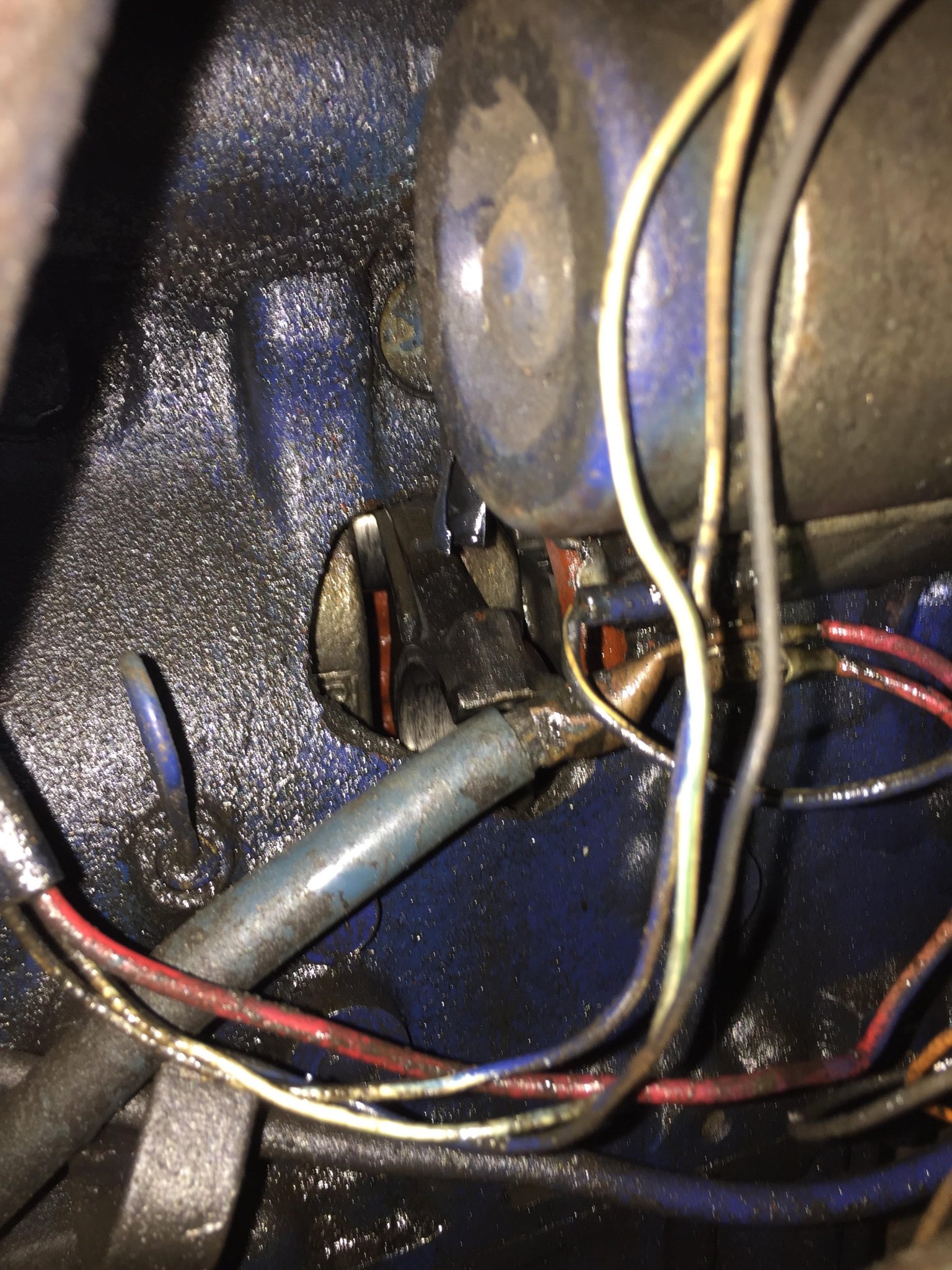

ok here's up close of the spare block...

Rip to the machine, it was my fault.

I know it will take me months to fix this but generally speaking -

What are the steps I will be taking to resolve this issue? I know its major surgery...

The goal is to take both engines out, and make one good solid engine. Go through it completely and fix that vital parts.

How hard is it lift the engines out, make one good one, and put back in the good one?

hole in the side of the block

This is a video of hole in the block

Ok here's a picture of the hole in the block

I was running L295DT leveling land, when engine exploded, spilled oil all over the ground etc.

Ok here's a parts tractor that has a good block/other parts that are needed for the fix

ok here's up close of the spare block...

Rip to the machine, it was my fault.

I know it will take me months to fix this but generally speaking -

What are the steps I will be taking to resolve this issue? I know its major surgery...

The goal is to take both engines out, and make one good solid engine. Go through it completely and fix that vital parts.

How hard is it lift the engines out, make one good one, and put back in the good one?