Show us your Shop and Equipment

- Thread starter Lil Foot

- Start date

Are some of the 427 hammers metric?

Not that I am aware of…Are some of the 427 hammers metric?

Besides…when I am reaching for a hammer, usually the bigger the better and something has likely gone wrong already…so I don’t care what persuasion it is.

The cordless drill mag base works great. I used it to drill and tap around 40 3/8”-16 holes through 3/4” steel.

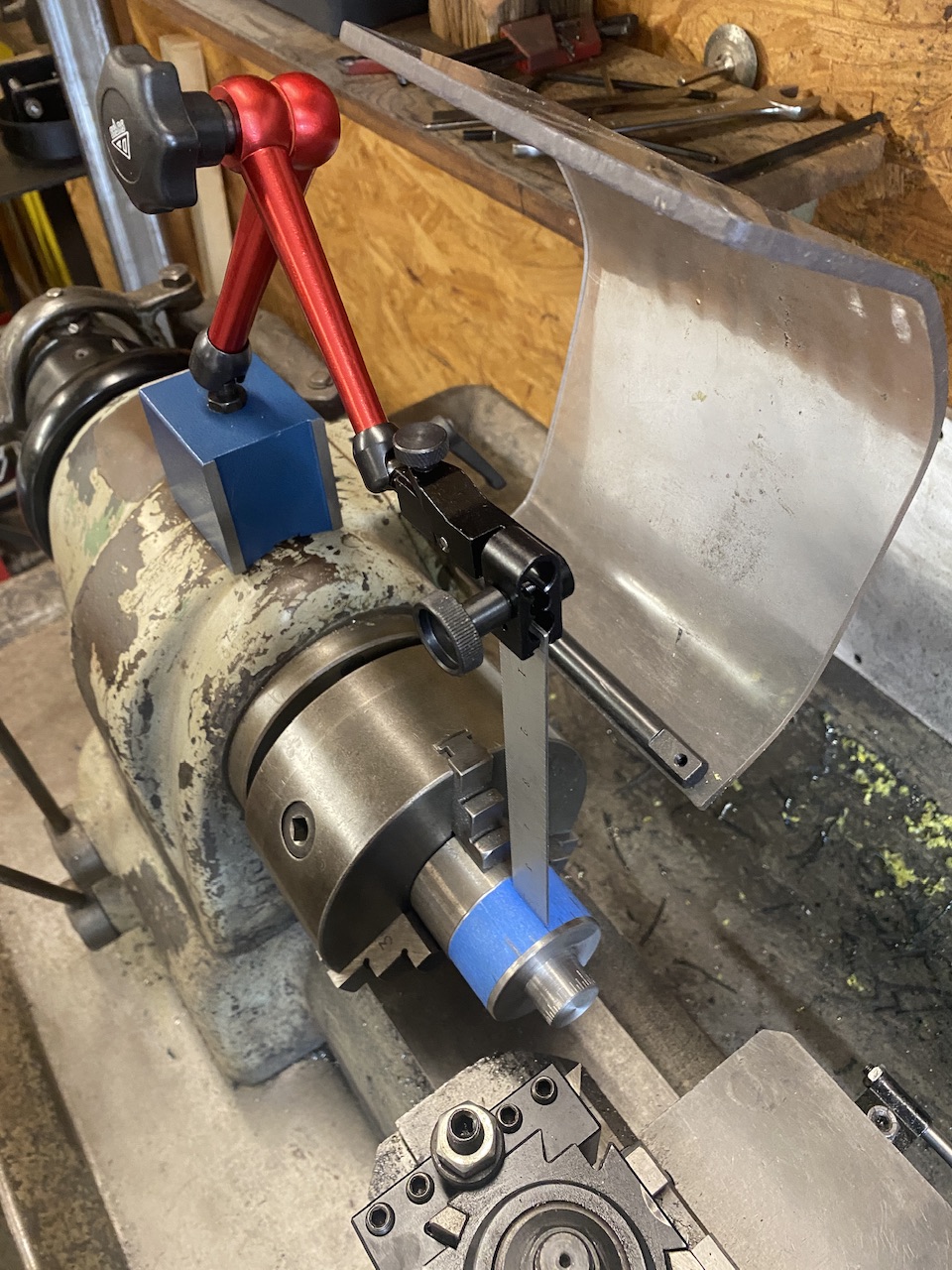

Today, I made a mag base tapping guide. It uses a 3/8” ratchet, a 6” extension and tap sockets. I have a Gearwrench ratcheting T handle tap wrench and a 3/8” square adapter that I can use in place of a 3/8” ratchet. Again, I had to get creative with setups on my lathe to machine it.

Today, I made a mag base tapping guide. It uses a 3/8” ratchet, a 6” extension and tap sockets. I have a Gearwrench ratcheting T handle tap wrench and a 3/8” square adapter that I can use in place of a 3/8” ratchet. Again, I had to get creative with setups on my lathe to machine it.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Might have to steal that design, looks pretty handy!The cordless drill mag base works great. I used it to drill and tap around 40 3/8”-16 holes through 3/4” steel.

Today, I made a mag base tapping guide. It uses a 3/8” ratchet, a 6” extension and tap sockets. I have a Gearwrench ratcheting T handle tap wrench and a 3/8” square adapter that I can use in place of a 3/8” ratchet. Again, I had to get creative with setups on my lathe to machine it.

View attachment 97335 View attachment 97336

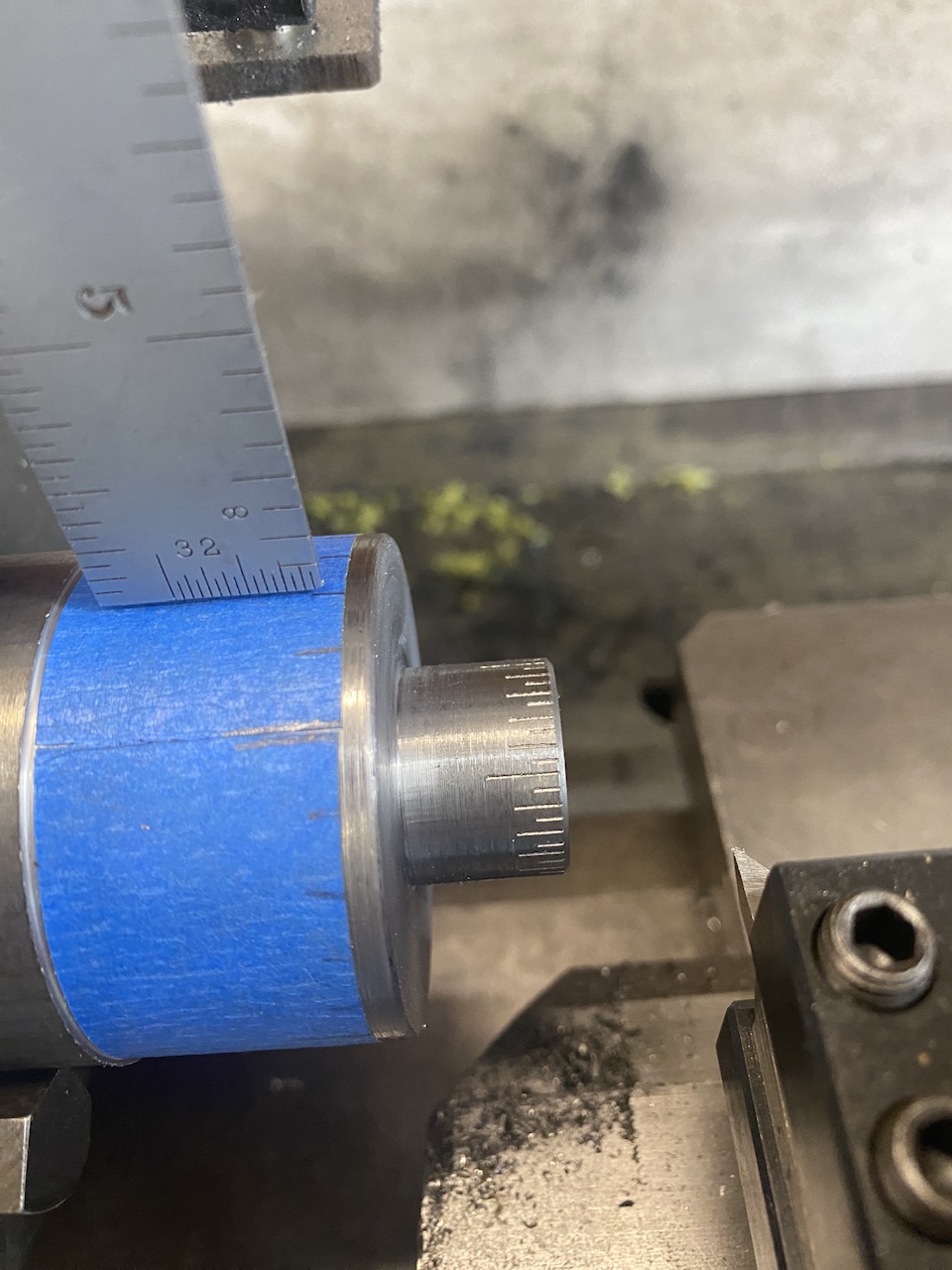

I’ve been thinking about buying or making a milling attachment for my lathe just to have. I picked up a nice 2-1/2” vise and yesterday I sketched the pieces I need to make. Today, I made the adjustment knob and cut 0.001” graduations on it using a lathe bit, magnetic indicator base, 6” scale, and masking tape with graduations on it.

RCW

Well-known member

Lifetime Member

Equipment

BX2360, FEL, MMM, BX2750D snowblower. 1953 Minneapolis Moline ZAU

My son, our youngest, works for a manufacturer of electrical connectors for aerospace, military and other applications.

Had plant tours for employees' families and retirees. My son is an EH&S guy, so he is all around the HUGE place, and is familiar with what a lot of the departments do.

Nothing was running, but the CNC, extrusion and injection molding equipment was really impressive and modern.

One small area had machines that looked 50-75 years old. He said they would work on prototype and small order stuff.

The connectors they make are so intricate and use a variety of metals and composites. They also do a bunch of different plating options. I'm sure everything must meet tight tolerances.

As evidenced by this thread, a lot of you guys are very skilled with this type of equipment.

You all probably would have understood more of it than I did.

Given a lot of issues you guys can relate to, there's no pictures to document the adventure......

It was really impressive. Glad I went and think sonny boy liked taking the "Ol' Man" on a tour.

Dad liked it too...

Had plant tours for employees' families and retirees. My son is an EH&S guy, so he is all around the HUGE place, and is familiar with what a lot of the departments do.

Nothing was running, but the CNC, extrusion and injection molding equipment was really impressive and modern.

One small area had machines that looked 50-75 years old. He said they would work on prototype and small order stuff.

The connectors they make are so intricate and use a variety of metals and composites. They also do a bunch of different plating options. I'm sure everything must meet tight tolerances.

As evidenced by this thread, a lot of you guys are very skilled with this type of equipment.

You all probably would have understood more of it than I did.

Given a lot of issues you guys can relate to, there's no pictures to document the adventure......

It was really impressive. Glad I went and think sonny boy liked taking the "Ol' Man" on a tour.

Dad liked it too...

Last edited:

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

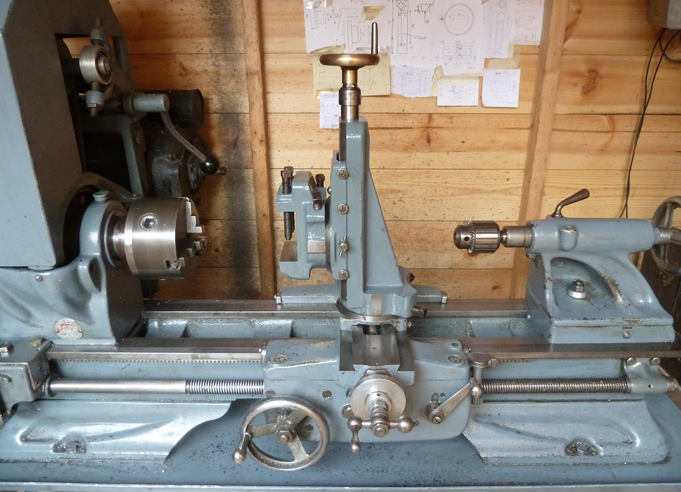

While it is not a full size vertical mill by any stretch of the imagination,

My Dad & I made a lot of cool stuff with a 10x24 Atlas with a milling attachment in the old days.

(like this)

My Dad & I made a lot of cool stuff with a 10x24 Atlas with a milling attachment in the old days.

(like this)

Betting its the same place my wife just retired from in Sidney. It is an impressive building smaller then the one they moved from.My son, our youngest, works for a manufacturer of electrical connectors for aerospace, military and other applications.

Had plant tours for employees' families and retirees. My son is an EH&S guy, so he is all around the HUGE place, and is familiar with what a lot of the departments do.

Nothing was running, but the CNC, extrusion and injection molding equipment was really impressive and modern.

One small area had machines that looked 50-75 years old. He said they would work on prototype and small order stuff.

The connectors they make are so intricate and use a variety of metals and composites. They also do a bunch of different plating options. I'm sure everything must meet tight tolerances.

As evidenced by this thread, a lot of you guys are very skilled with this type of equipment.

You all probably would have understood more of it than I did.

Given a lot of issues you guys can relate to, there's no pictures to document the adventure......

It was really impressive. Glad I went and think sonny boy liked taking the "Ol' Man" on a tour.

Dad liked it too...

Made an indicator holder for my lathe. It locks onto the spindle taper the same way as the chucks. I used the milling attachment to cut a keyway into a shaft and to mill a spacer to raise the top plate on the milling attachment.

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Got tired of chasing my jewelers screwdrivers around in the bottom of the screwdriver drawer:

Made some improvements to my Hardinge lathe. It’s what’s referred to as a second op lathe. The carriage doesn’t feed left and right like a traditional lathe. It slides on the ways and is locked in place with a handle at the back. I made new dovetail pieces and a gib to replace the lock and added a lead screw and handwheel.