Hey guys what’s up? I haven’t been on here for a while as my kubota has been dominating all this snow we have in Minnesota.

Anyways I ran my b8200 for about 2 to 2.5 hours last Sunday and after I parked it I noticed a puddle on the floor about the size of my fist.

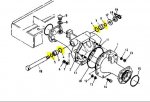

A couple months ago i had a bunch of drama with this tractor but i got everything figured out and in the process the tractor got all new fluids front to back. The front axle was filled with 80-90w gear oil. When I say filled I mean it was filled to the brim. Now this leak appears to be at the seal of the front output driveshaft where it meets the outer sheeth or tube. I also noticed some seepage up around the axle pivot pin where it mounts to the frame. I saw a similar post with the same possible issue.

Now did I simply overfill the axle from the first place and the pressure build up is causing leakage?

Or should I look into replacing the seal as it has lost some of its spring and seems to be a bit sloppy.

Lastly I checked my fluid level in the axle and it is lower due to the leakage, I can see about half the axle shaft and the top layer of fluid was a bit foamy. Should I leave it be or top it off again? I have read that some axles are vented with a breather, I can not seem to locate any type of vent.

Thanks!

Anyways I ran my b8200 for about 2 to 2.5 hours last Sunday and after I parked it I noticed a puddle on the floor about the size of my fist.

A couple months ago i had a bunch of drama with this tractor but i got everything figured out and in the process the tractor got all new fluids front to back. The front axle was filled with 80-90w gear oil. When I say filled I mean it was filled to the brim. Now this leak appears to be at the seal of the front output driveshaft where it meets the outer sheeth or tube. I also noticed some seepage up around the axle pivot pin where it mounts to the frame. I saw a similar post with the same possible issue.

Now did I simply overfill the axle from the first place and the pressure build up is causing leakage?

Or should I look into replacing the seal as it has lost some of its spring and seems to be a bit sloppy.

Lastly I checked my fluid level in the axle and it is lower due to the leakage, I can see about half the axle shaft and the top layer of fluid was a bit foamy. Should I leave it be or top it off again? I have read that some axles are vented with a breather, I can not seem to locate any type of vent.

Thanks!