Good afternoon,

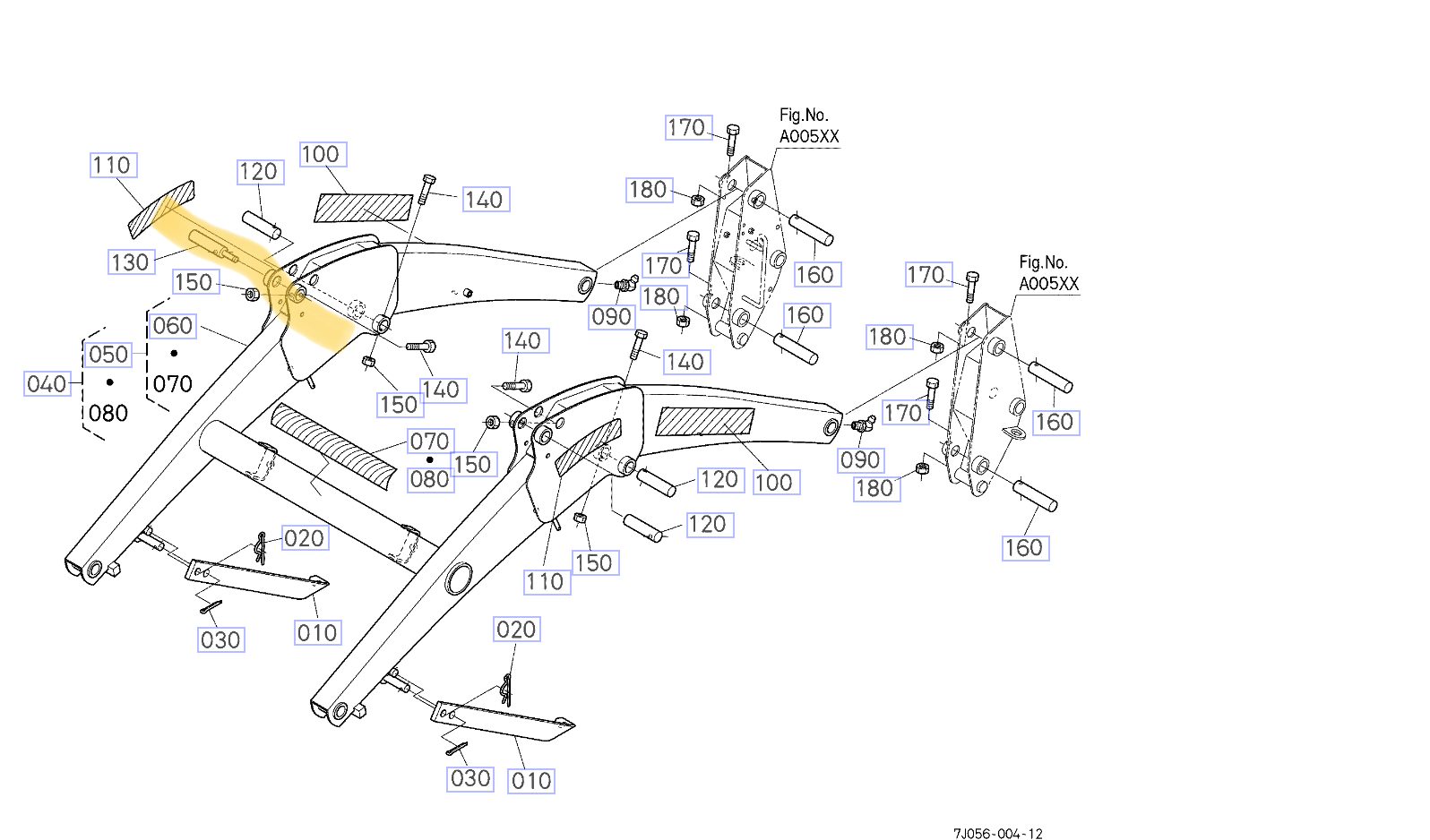

I have a fair bit of slop one of the pins in the loader (LA534) on my tractor (B2650).

The is the upper cylinder pin in the below screenshot. I have what seems to me an unusual amount of slop in the joint (tractor has 250 hrs, was not well taken care of before I got it recently).

Any idea what an acceptable amount of play is between the pin and the bushings?

I measure the following:

Pin: 24.81mm

Outboard bushing on loader: 25.63mm

Cylinder bushing: 25.37mm

Inboard bushing on loader: 25.58mm.

I have a video but I need to be verified by you tube before I can submit the link.

I have a fair bit of slop one of the pins in the loader (LA534) on my tractor (B2650).

The is the upper cylinder pin in the below screenshot. I have what seems to me an unusual amount of slop in the joint (tractor has 250 hrs, was not well taken care of before I got it recently).

Any idea what an acceptable amount of play is between the pin and the bushings?

I measure the following:

Pin: 24.81mm

Outboard bushing on loader: 25.63mm

Cylinder bushing: 25.37mm

Inboard bushing on loader: 25.58mm.

I have a video but I need to be verified by you tube before I can submit the link.