Hello All,

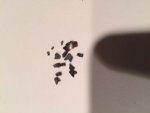

I've been trying to figure out what's wrong with the loader on my 1983 L235DT. It has been moving really slow and it cannot pick up any weight. The 3 PT hitch has no trouble picking up a 5" box blade but it doesn't seem to be as fast as it used to be. I took a look at the hydraulic relief valve and found two bits of metal inside the casing (photos are attached) . The larger piece is just under 1/4" long and the other piece is about half that size. The larger piece looks smooth on one side. What steps should I take next?

Thanks,

Fred

I've been trying to figure out what's wrong with the loader on my 1983 L235DT. It has been moving really slow and it cannot pick up any weight. The 3 PT hitch has no trouble picking up a 5" box blade but it doesn't seem to be as fast as it used to be. I took a look at the hydraulic relief valve and found two bits of metal inside the casing (photos are attached) . The larger piece is just under 1/4" long and the other piece is about half that size. The larger piece looks smooth on one side. What steps should I take next?

Thanks,

Fred

Attachments

-

38.4 KB Views: 243

-

47.2 KB Views: 216