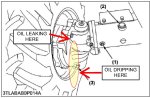

Hi all. I have an L4060 with a slowly leaking front axle seal. I do not use my tractor much.....only about 20 hours per year. It has 190 hours on it. I use it mainly for maintaining my driveway and carrying cut-up deadfall out of the woods. It is garage-kept. Anyway, I have a slow axle seal leak at the driver-side wheel. 2 years ago, I was moving some stacks of lumber around and I was maxing out the FEL, and that's when the leak started. It's not getting worse and I check the fluid level each time I use it.

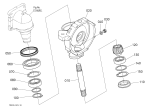

I'm a pretty lousy mechanic. I have a tendency to screw problems up worse than they were before my attempts to fix them if they are anything beyond basic maintenance. I don't have a trailer to haul my tractor and when it goes to the dealer, it's a $400 round-trip roll-back charge plus the dealer's repair bill. I've read quite a few comments that the front axle seals are not difficult to replace, but I haven't seen any YouTube videos of an L4060 front axle seal replacement. I have a WSM and it does not specifically address replacing the front axle seal. It deals with more substantial front axle repairs, but there is a photo in the WSM showing the removal of the bevel gear case and front gear case as a unit that looks easy enough for me to handle. Is that what needs to be done to replace the leaking seal or are there other seals in that assembly that could be causing the leak? (please see attached photos with notes and questions). Any guidance would be greatly appreciated.

I'm a pretty lousy mechanic. I have a tendency to screw problems up worse than they were before my attempts to fix them if they are anything beyond basic maintenance. I don't have a trailer to haul my tractor and when it goes to the dealer, it's a $400 round-trip roll-back charge plus the dealer's repair bill. I've read quite a few comments that the front axle seals are not difficult to replace, but I haven't seen any YouTube videos of an L4060 front axle seal replacement. I have a WSM and it does not specifically address replacing the front axle seal. It deals with more substantial front axle repairs, but there is a photo in the WSM showing the removal of the bevel gear case and front gear case as a unit that looks easy enough for me to handle. Is that what needs to be done to replace the leaking seal or are there other seals in that assembly that could be causing the leak? (please see attached photos with notes and questions). Any guidance would be greatly appreciated.

Attachments

-

302.3 KB Views: 232

-

145.6 KB Views: 235