hello all, i have an l3600dt-gst that has suddenly started leaking hydraulic fluid profusely but i am having a hard time finding where it is actually coming from.

i was running the loader and as i was going back and forth i noticed dribble lines on the ground and i got off and looked under the tractor and there was fluid dripping is several spots. where the front drive shaft enters the front axle, all along the front drive shaft outer tubes and the oil pans and the case just behind the block along with what looked like a drain plug with a little nub in the center.

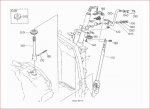

after parking and letting the drips stop i checked the hydraulic oil sight glass at the back and there was none visible. looking underneath it was still hard to see where the oil was coming out. it did seam that everything oil was dripping from was related to the 4x4 so i took it out of 4x4 and started it up. it ran fine loader worked and 3 point cycled up and down. it did not start leaking a bunch right away but did start to dip a bit and it seamed to be coming from that plug with the nub in the center. you can see it in the pic just behind the orange cross member. the little nub almost seams like a plunger and is free to wobble and can be pushed up with no resistance. i had seen this thing before and other than the oil it is no different.

any ideas on what this is and what might be the fluid leak problem. this was definately sudden on set. i changed engine oil last week and everything down there was bone dry no oil leaks and then just today it started puking. i am considering topping off the hydraulics and running it to see if it starts leaking again with more fluid available but it seams like if the loader and 3 point are working there should be enough to leak?

can you recomend any online source where i can buy a service manual and get it as an instant download?

dont know if it is related but earlier this season the PTO "broke" as in it will not disengage, i checked the adjustment but it seams to be an internal problem

also hydraulics to the loader seamed to be less than par towards the end of the season, it all worked but did not seam as strong. often had to bring the rpms up higher than expected to get the job done.

hope i can get this figured out asap as we have crops that need to come in and doing it by hand is not a happy thought.

thanks

kenny

i was running the loader and as i was going back and forth i noticed dribble lines on the ground and i got off and looked under the tractor and there was fluid dripping is several spots. where the front drive shaft enters the front axle, all along the front drive shaft outer tubes and the oil pans and the case just behind the block along with what looked like a drain plug with a little nub in the center.

after parking and letting the drips stop i checked the hydraulic oil sight glass at the back and there was none visible. looking underneath it was still hard to see where the oil was coming out. it did seam that everything oil was dripping from was related to the 4x4 so i took it out of 4x4 and started it up. it ran fine loader worked and 3 point cycled up and down. it did not start leaking a bunch right away but did start to dip a bit and it seamed to be coming from that plug with the nub in the center. you can see it in the pic just behind the orange cross member. the little nub almost seams like a plunger and is free to wobble and can be pushed up with no resistance. i had seen this thing before and other than the oil it is no different.

any ideas on what this is and what might be the fluid leak problem. this was definately sudden on set. i changed engine oil last week and everything down there was bone dry no oil leaks and then just today it started puking. i am considering topping off the hydraulics and running it to see if it starts leaking again with more fluid available but it seams like if the loader and 3 point are working there should be enough to leak?

can you recomend any online source where i can buy a service manual and get it as an instant download?

dont know if it is related but earlier this season the PTO "broke" as in it will not disengage, i checked the adjustment but it seams to be an internal problem

also hydraulics to the loader seamed to be less than par towards the end of the season, it all worked but did not seam as strong. often had to bring the rpms up higher than expected to get the job done.

hope i can get this figured out asap as we have crops that need to come in and doing it by hand is not a happy thought.

thanks

kenny