Hello all. My l185's 3PT arms won't go low enough to work properly with the quick hitch. From what little information I can find, it looks like adjusting the feedback rod should allow it to go lower. Is that accurate? It does seem like the feedback rod is to high as it will continue to try to raise at the full height. Is there any other adjustments that control how low the arms go?

l185 3pt height adjustment

- Thread starter Mung

- Start date

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Thanks! Just wanted to make sure before I started messing with it. There is not a lot of information even in the manuals. They talk about the top height, not the bottom.Yes you need to adjust the feed back for max height limit to get the optimum lowering amount.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

On the left lift rod there should be two holes max lowering height is achieved with the bolt in the bottom hole.

Very good, I will check that too.On the left lift rod there should be two holes max lowering height is achieved with the bolt in the bottom hole.

Russell King

Well-known member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

And one other thing to check…since my L185 lift arms go very close to the ground at the lowest setting.

On the position control lever Kubota provides a stopper that can be set to limit the position of the lever in the dow direction so that you can always return to the same position. Generally there is a wing nut clamp that stopper in place.

is that stopper all the way down or is it limiting how far the lever can move? If it can be moved further down than presently set please move it to see if it resolves the problem

On the position control lever Kubota provides a stopper that can be set to limit the position of the lever in the dow direction so that you can always return to the same position. Generally there is a wing nut clamp that stopper in place.

is that stopper all the way down or is it limiting how far the lever can move? If it can be moved further down than presently set please move it to see if it resolves the problem

The lever is bottomed out in the notch, so it can't go any lower. Hopefully I can get over to my property this morning between meetings and mess with the feedback arm.And one other thing to check…since my L185 lift arms go very close to the ground at the lowest setting.

On the position control lever Kubota provides a stopper that can be set to limit the position of the lever in the dow direction so that you can always return to the same position. Generally there is a wing nut clamp that stopper in place.

is that stopper all the way down or is it limiting how far the lever can move? If it can be moved further down than presently set please move it to see if it resolves the problem

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

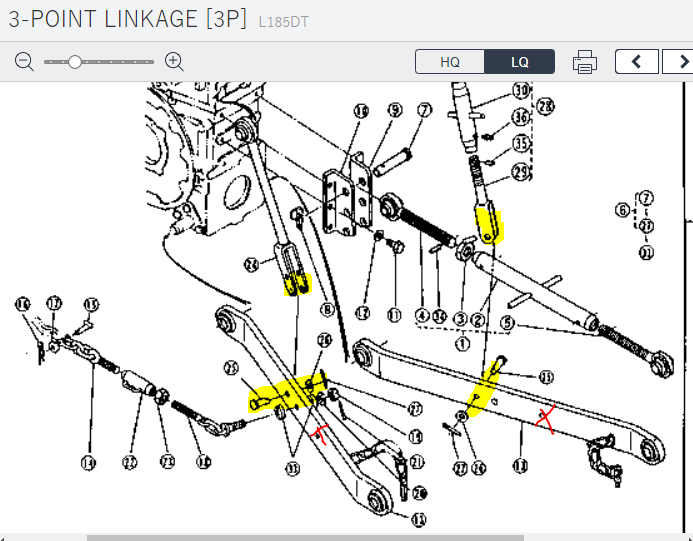

You ever hear the saying a picture is worth a thousand words...

You're lift links are in the wrong holes!

You're lift links are in the wrong holes!

Thanks! Looks like the person I bought the tractor from or one of the probably many before him messed with a few things.You ever hear the saying a picture is worth a thousand words...

You're lift links are in the wrong holes!

View attachment 95892

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

You should notice a huge difference!Thanks! Looks like the person I bought the tractor from or one of the probably many before him messed with a few things.

You could also get a set of these to take the sloop out of the connections.

or these:

TK95029 Fits CAT 1 Quick Hitch Adapter Bushing Kit Fits Category 1 3-Point Hitch | eBay

Find many great new & used options and get the best deals for TK95029 Fits CAT 1 Quick Hitch Adapter Bushing Kit Fits Category 1 3-Point Hitch at the best online prices at eBay! Free shipping for many products!

www.ebay.com

I have some of those, just haven't put them fully on yet. Any tips on how to get the roll pins in on those suckers? The vice grip trick doesn't seem to be working and the bushings want to roll when I am hammering in the pin.You should notice a huge difference!

You could also get a set of these to take the sloop out of the connections.

or these:

TK95029 Fits CAT 1 Quick Hitch Adapter Bushing Kit Fits Category 1 3-Point Hitch | eBay

Find many great new & used options and get the best deals for TK95029 Fits CAT 1 Quick Hitch Adapter Bushing Kit Fits Category 1 3-Point Hitch at the best online prices at eBay! Free shipping for many products!www.ebay.com

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Yea they can be a pain.

Rotate the original pins so the holes are horizontal.

Install the bushing on the pin, then put a punch or a spare bolt in the hole to keep them from spinning and moving.

Then drive the roll pin though the hole pushing the punch out.

Rotate the original pins so the holes are horizontal.

Install the bushing on the pin, then put a punch or a spare bolt in the hole to keep them from spinning and moving.

Then drive the roll pin though the hole pushing the punch out.

Thanks, I will try that.Yea they can be a pain.

Rotate the original pins so the holes are horizontal.

Install the bushing on the pin, then put a punch or a spare bolt in the hole to keep them from spinning and moving.

Then drive the roll pin though the hole pushing the punch out.

Russell King

Well-known member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

I noticed that you have a few “modifications” on the 3 point that work but you would probably be happier if they were more consistent with the original design. And most parts are still available at the dealership.

1) at the lower lift arm to tractor pin you have a bolt through the hole to retain the arm. I believe that should be a lynchpin just like at the top of your picture.

2) the top link is pretty long for the tractor and you could replace it with one that is closer to the correct length. The top link is 16.5 to 27 inches hole to hole on my tractor and seems like original equipment. I would recommend not getting this from the dealer.

3) At the check chain to tractor the pin looks like original and has a tab that puts the pin hole in a position to put the pin in easily. There are currently cotter pins retaining the pin but a hair pin clip can be removed easily to allow for installation of the arms to the implements without having to unscrew the turnbuckle. This may be of no value to you since you have the quick attach on.

4). On the same location but far side of the tractor the shackle has been replaced with something like a chain link. It would be nice to replace it with original parts like 15 to 17 in the parts diagram above.

1) at the lower lift arm to tractor pin you have a bolt through the hole to retain the arm. I believe that should be a lynchpin just like at the top of your picture.

2) the top link is pretty long for the tractor and you could replace it with one that is closer to the correct length. The top link is 16.5 to 27 inches hole to hole on my tractor and seems like original equipment. I would recommend not getting this from the dealer.

3) At the check chain to tractor the pin looks like original and has a tab that puts the pin hole in a position to put the pin in easily. There are currently cotter pins retaining the pin but a hair pin clip can be removed easily to allow for installation of the arms to the implements without having to unscrew the turnbuckle. This may be of no value to you since you have the quick attach on.

4). On the same location but far side of the tractor the shackle has been replaced with something like a chain link. It would be nice to replace it with original parts like 15 to 17 in the parts diagram above.

Thanks, I will try to tackle those things a bit at a time. When my house is finished and I have my workshop and tools over on the new property, I plan to start fixing things up on her. I won't do a full restoration, but something that looks good while not making me afraid to use her in the way intended.I noticed that you have a few “modifications” on the 3 point that work but you would probably be happier if they were more consistent with the original design. And most parts are still available at the dealership.

1) at the lower lift arm to tractor pin you have a bolt through the hole to retain the arm. I believe that should be a lynchpin just like at the top of your picture.

2) the top link is pretty long for the tractor and you could replace it with one that is closer to the correct length. The top link is 16.5 to 27 inches hole to hole on my tractor and seems like original equipment. I would recommend not getting this from the dealer.

3) At the check chain to tractor the pin looks like original and has a tab that puts the pin hole in a position to put the pin in easily. There are currently cotter pins retaining the pin but a hair pin clip can be removed easily to allow for installation of the arms to the implements without having to unscrew the turnbuckle. This may be of no value to you since you have the quick attach on.

4). On the same location but far side of the tractor the shackle has been replaced with something like a chain link. It would be nice to replace it with original parts like 15 to 17 in the parts diagram above.

Thanks everyone. Got the arms in the right place and things are much better. Got the roll pins in on the hog as well.