Hello everyone. I have a Jacobsen HR5111 comercial mower with the V2203-DI B engine. it's a 92 or 93 year. The injector pump is leaking at the top where the lines go in. I imagine it's just an o ring or something bu before I tear into this I'd like to have a manual or something. Does anyone have a PDF file on the fuel system or injector pump they could sent me, or any real good technical advice before I tear this apart ? I want to get the mower fixed before mowing season. This is for my personal yard but still want to have it repaired. Some will say leave this to the professionals but I assure you it will be no problem, rebuilding engines or components is no issue for me, just like to have the manual for doing a proper job. Hope someone can help. thanks.

Kubota V2203 injector pump problem

- Thread starter tak82

- Start date

Welcome to the forum.

A suggestion-- when you have questions is to go to the top of the page where it says "SEARCH", enter your basic question, and perhaps it has already be addressed.

I don't know much of anything about your specific engine, but I did a search and found this. Maybe it will help.

http://www.scribd.com/doc/43717372/Kubota-V2203-Workshop-Manual

A suggestion-- when you have questions is to go to the top of the page where it says "SEARCH", enter your basic question, and perhaps it has already be addressed.

I don't know much of anything about your specific engine, but I did a search and found this. Maybe it will help.

http://www.scribd.com/doc/43717372/Kubota-V2203-Workshop-Manual

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Yes it has an O-ring in it.

P/N 14611-51200

http://www.colemanequip.com/Parts_Detail.asp?partID=544222

P/N 14611-51200

http://www.colemanequip.com/Parts_Detail.asp?partID=544222

Attachments

-

66.3 KB Views: 47,683

I know this is an older post, but it is very relevant to a problem I'm having.

I just replaced the V2203 in my 753 Bobcat. I heard the motor run before I installed and the injector pump didn't leak. I'm guessing I jiggled things around when I removed and re-applied the injector lines.

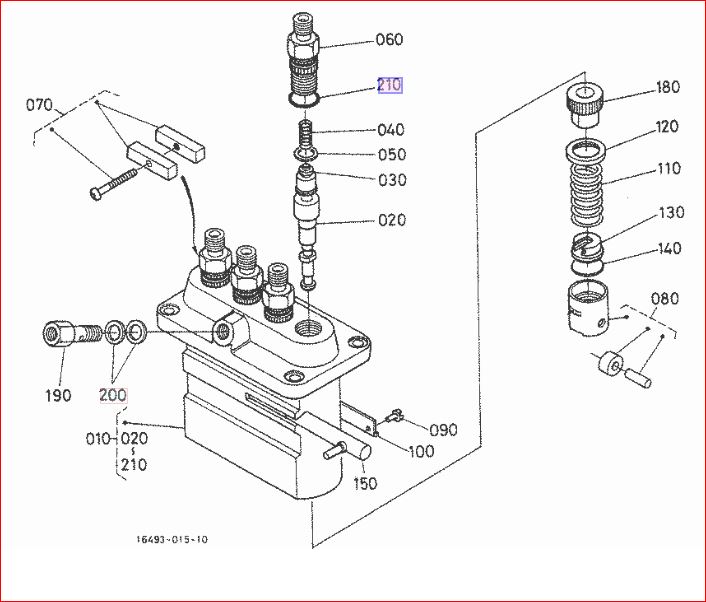

I'm planning on replacing the o-rings on the injector pistons(?). My question is this: I had read that the piston needed to be replaced in the "exact" position it was taken out of. Is that so the roller (080) will position on the cam correctly?

I haven't disassembled yet. Probably going to wait until I can get new o-rings.

I just replaced the V2203 in my 753 Bobcat. I heard the motor run before I installed and the injector pump didn't leak. I'm guessing I jiggled things around when I removed and re-applied the injector lines.

I'm planning on replacing the o-rings on the injector pistons(?). My question is this: I had read that the piston needed to be replaced in the "exact" position it was taken out of. Is that so the roller (080) will position on the cam correctly?

I haven't disassembled yet. Probably going to wait until I can get new o-rings.

You need to get part #60 out to replace the O-ring. #40 is a spring, #30 is a check valve.

If you are real careful you can remove #60 and it will come up off the spring and not disrupt anything else. Install the new O-ring and put it right back on. I think #50 is a copper seal. Probably ought to replace that seal also.

If you are real careful you can remove #60 and it will come up off the spring and not disrupt anything else. Install the new O-ring and put it right back on. I think #50 is a copper seal. Probably ought to replace that seal also.

Spot on D2Cat

I remembered I has some o-rings left over from the gasket kit I bought.

Good thing I didn't throw them out when I was "done".

I just replaced the o-rings got it fired up and no leaks.

Thanks

I remembered I has some o-rings left over from the gasket kit I bought.

Good thing I didn't throw them out when I was "done".

I just replaced the o-rings got it fired up and no leaks.

Thanks

I have exactly same problem as Stumblinalong. So:

1) Did you replace 050 copper washer or can I lwavit alone?

2) Would you see the O ring is standard that I can find in O ring kit or is it special in any way.

3) Did you mark rotational position of each outlet?

4) Any tricky bit to watch out for?

1) Did you replace 050 copper washer or can I lwavit alone?

2) Would you see the O ring is standard that I can find in O ring kit or is it special in any way.

3) Did you mark rotational position of each outlet?

4) Any tricky bit to watch out for?

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

If the pump is working fine, and the only problem is an external leak, then all you need to remove is #60 and #210, if the spring washer or check valve comes out make sure they go back in the same hole and the right direction.I have exactly same problem as Stumblinalong. So:

1) Did you replace 050 copper washer or can I lwavit alone?

2) Would you see the O ring is standard that I can find in O ring kit or is it special in any way.

3) Did you mark rotational position of each outlet?

4) Any tricky bit to watch out for?

You need to torque the valve holder down to proper specs, then reinstall the retainers.

You can mic the o-rings and get ones that match to replace them.

Thank you for the reply. I thought #060 rotation determined timing (something to do with amount of fuel), and #070 locked rotational position of #060. If this is incorrect, then what is function of #070?

06 is called "the delivery valve HOLDER" it does what's implied.. has nothing to do w timing & has nothing to do w/ where it WAS.. U simply tighten them to the proper torque & 07 keeps them from turning when u tighten the injector lines..

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

YEP...What he said!06 is called "the delivery valve HOLDER" it does what's implied.. has nothing to do w timing & has nothing to do w/ where it WAS.. U simply tighten them to the proper torque & 07 keeps them from turning when u tighten the injector lines..

Thank you both, job done. Two were leaking, I marked their rotational position anyway, matched o ring from a kit (old ones were compressed, hardened, and brittle). I didn't have new small copper washers so left the old ones in. I was surprised I was able to tighten the delivery valve holders by an extra 1/4 turn. All works and no leaks now. Thanks again.

While we are on this subject... a couple of observations/questions.

1. If an O-ring (#210 in wolfman's post) is leaking, then the copper seal (= copper washer, #50) must have been leaking as well (or was before reinstalling the delivery valve holder).

2. My experience with an older 6 cyl (S2600) Kubota engine confirmed what Wolfman and others on the forum said: re-torquing a DVH won't necessarily fix a leaking copper seal. (In my case the copper seals were eroded with tiny radial valleys hardly visible without magnification, but maybe un-eroded ones can be torqued successfully.)

3. The S2600 parts list doesn't show an O-ring, only the copper seal.

Can anyone shed some light on what to me seems a bit of a mystery:

Q1. is the function of the O ring really to stop fuel leaking out, or is it to keep rubbish/corrosion from building up in the gap between the DVH and the pump body, which would then fall into the pump when unscrewing the DVH?

Q2. if the O-ring is the fuel seal, why have a copper seal?

Q3. is the O-ring a later improvement on the pump design, or was it always there, just not shown in the S2600 or other parts diagrams?

Does fixing a leaking DVH deserves it's own sticky? The advice from D2Cat, Wolfman, and thepumpguysc (http://www.orangetractortalks.com/forums/showthread.php?t=38811&highlight=holder) helped me. And according to Messicks this particular DVH is used on 40-50 different tractor models (would be great to be able to translate that to specific engine models, but I haven't figured that out).

1. If an O-ring (#210 in wolfman's post) is leaking, then the copper seal (= copper washer, #50) must have been leaking as well (or was before reinstalling the delivery valve holder).

2. My experience with an older 6 cyl (S2600) Kubota engine confirmed what Wolfman and others on the forum said: re-torquing a DVH won't necessarily fix a leaking copper seal. (In my case the copper seals were eroded with tiny radial valleys hardly visible without magnification, but maybe un-eroded ones can be torqued successfully.)

3. The S2600 parts list doesn't show an O-ring, only the copper seal.

Can anyone shed some light on what to me seems a bit of a mystery:

Q1. is the function of the O ring really to stop fuel leaking out, or is it to keep rubbish/corrosion from building up in the gap between the DVH and the pump body, which would then fall into the pump when unscrewing the DVH?

Q2. if the O-ring is the fuel seal, why have a copper seal?

Q3. is the O-ring a later improvement on the pump design, or was it always there, just not shown in the S2600 or other parts diagrams?

Does fixing a leaking DVH deserves it's own sticky? The advice from D2Cat, Wolfman, and thepumpguysc (http://www.orangetractortalks.com/forums/showthread.php?t=38811&highlight=holder) helped me. And according to Messicks this particular DVH is used on 40-50 different tractor models (would be great to be able to translate that to specific engine models, but I haven't figured that out).

As with any forum, theres bad info being given.. & just because it worked "for you" doesn't mean THATS the proper way..

The oring has always been there.. & maybe the reason its not shown is because they don't want u going into the pump.?? THATS WHY there are tamper proof screws on it & the correct tool costs over 300.00..{5 sided bolt/chevron}

The copper gasket is to seal the HOLDER to the DV.. the inside of the holder is not a machined lapped surface & to take out any deformities, they used a copper crush washer.. Its a 1 time use gasket or atleast its supposed to be..& should be replaced at the time of removing the holder.

The del. valve is a lapped surface & its a metal to metal seal against the bottom.{barrel}

I hope this clears up any confusion.. Brought to you from your friendly neighborhood pump guy..

The oring has always been there.. & maybe the reason its not shown is because they don't want u going into the pump.?? THATS WHY there are tamper proof screws on it & the correct tool costs over 300.00..{5 sided bolt/chevron}

The copper gasket is to seal the HOLDER to the DV.. the inside of the holder is not a machined lapped surface & to take out any deformities, they used a copper crush washer.. Its a 1 time use gasket or atleast its supposed to be..& should be replaced at the time of removing the holder.

The del. valve is a lapped surface & its a metal to metal seal against the bottom.{barrel}

I hope this clears up any confusion.. Brought to you from your friendly neighborhood pump guy..

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Not to pick on you, but some Kubota pumps have O-rings, some do not, Some kubota pumps have tamper proof retainers some do not.As with any forum, theres bad info being given.. & just because it worked "for you" doesn't mean THATS the proper way..

The oring has always been there.. & maybe the reason its not shown is because they don't want u going into the pump.?? THATS WHY there are tamper proof screws on it & the correct tool costs over 300.00..{5 sided bolt/chevron}

In closing every pump situation on a kubota can be completely different!

Thanks for the clarification NIW. There seems to be a reasonable call for info on fixing the leaks from the delivery valve holders on these (Bosch K type?) pumps (this forum and quite a few others), do you think a sticky or article would be useful? Or are there too many differences within that particular fix (the differences in pumps you refer to) to make it worthwhile?

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

I've seen and worked on quite a few different pumps and they are all different in one aspect or another, it's hard to nail down a limited parameters of "do this do that" information.Thanks for the clarification NIW. There seems to be a reasonable call for info on fixing the leaks from the delivery valve holders on these (Bosch K type?) pumps (this forum and quite a few others), do you think a sticky or article would be useful? Or are there too many differences within that particular fix (the differences in pumps you refer to) to make it worthwhile?

Thanks, given your experience it sounds like I should shelve that idea.I've seen and worked on quite a few different pumps and they are all different in one aspect or another, it's hard to nail down a limited parameters of "do this do that" information.