Okay I am having issues and the dealership has not been able to figure this out either.

I have a kubota B2650 and Snow Blower B2781B. There is a bolt in the side of my PTO gear box that is used to provide tension on the sprocket to keep the chain tight. And it keeps breaking. I had this happen last season (its 3 seasons old bought brand new). SO i talked to dealership got a new bolt, had to tear this thing apart to get it back together. Made sure everything was aligned and running. Mid season everything came lose again. I tore it all down and re tightened everything down and it was fine.

Jump to this season - first time out tensioner broke again and i had to rebuild it all again, and everything seemed fine. 2nd time out and the dam thing literally exploded with parts all over the driveway. Plastic casing on drive shaft shredded, broke the protective guards, broke chain and I assume its because tensioner bolt broke again under use!

So I filed a claim with Kubota Insurance and dropped it off for repair. Now almost 2000.00 in repairs and the second time I take it out to remove 3-4 inches of soft snow on my 1/4 mile driveway I senses a vibration, shut it all down and the darn tensioner bolt is broken AGAIN!

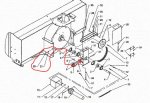

There has to be something I and the dealership is missing! What would cause that to break again? I am assuming some ungodly torque or force is breaking it. See pictures attached.

Does anyone have ANY ideas? I am desperate. In the middle of snow season and we have gotten over 40 inches of snow in December.

FYI - Now dealership wants me to get machine and snowblower into the dealership. At My cost! I do not have a trailer big enough and would cost over $200.00 each way!

I am so freaking irritated. Been out of work since June. I purchased a grading pusher blade a week ago to get by (1800.00) but now they want the whole kit and kaboodle! I'm screwed!!

I have a kubota B2650 and Snow Blower B2781B. There is a bolt in the side of my PTO gear box that is used to provide tension on the sprocket to keep the chain tight. And it keeps breaking. I had this happen last season (its 3 seasons old bought brand new). SO i talked to dealership got a new bolt, had to tear this thing apart to get it back together. Made sure everything was aligned and running. Mid season everything came lose again. I tore it all down and re tightened everything down and it was fine.

Jump to this season - first time out tensioner broke again and i had to rebuild it all again, and everything seemed fine. 2nd time out and the dam thing literally exploded with parts all over the driveway. Plastic casing on drive shaft shredded, broke the protective guards, broke chain and I assume its because tensioner bolt broke again under use!

So I filed a claim with Kubota Insurance and dropped it off for repair. Now almost 2000.00 in repairs and the second time I take it out to remove 3-4 inches of soft snow on my 1/4 mile driveway I senses a vibration, shut it all down and the darn tensioner bolt is broken AGAIN!

There has to be something I and the dealership is missing! What would cause that to break again? I am assuming some ungodly torque or force is breaking it. See pictures attached.

Does anyone have ANY ideas? I am desperate. In the middle of snow season and we have gotten over 40 inches of snow in December.

FYI - Now dealership wants me to get machine and snowblower into the dealership. At My cost! I do not have a trailer big enough and would cost over $200.00 each way!

I am so freaking irritated. Been out of work since June. I purchased a grading pusher blade a week ago to get by (1800.00) but now they want the whole kit and kaboodle! I'm screwed!!

Attachments

-

54.8 KB Views: 599