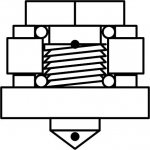

I had to install a heli-coil after stripping threads on the HST case at a banjo pipe joint (see photo). Now I am having problems getting the copper washer between the pipe and the HST to seal. I used new copper washers on the joint. I cannot find a torque spec for the connection and maybe that is why the joint is leaking. I do not want to strip the HST case threads again so I'm wondering if there is a better washer available that can be used to seal this joint? Suggestions or comments would be most appreciated to help me out of this mess.

Attachments

-

84.1 KB Views: 396