Rob

Member

Lifetime Member

Equipment

B6000DT / B7100DP /B8200DT/L225/Globe PTO Chipper/Lewis Backhoe/huxley TR66

Hi everyone and good evening to you all, I am looking for more help I’m afraid so here goes.

I am adding extra hydraulic capacity to my B7100 , I already have the factory fitted hydraulic out from the rear 3pt spool for a single acting item , but, I want to keep it for my soon to be constructed tipping trailer so extra capacity is needed for my other items.

My question is this.

I have recently aquired a double acting single way spool valve made by”dukes fluid power” it’s a 1618AL.

It has the following ports , two ports marked “IN” & “OUT” on the front lower edge of the spool body, Two ports Marked “A” & “B” on the top of the spool body and a single port Marked “PB” on the side of the spool body.

Spec of valve:

DANFOSS FLUID POWER

ENGINEERING TEST ORDER

ETO# 156B2214

(was 1618-AL)

EASLEY OPERATION DATE: 01.06.88 REV CHANGE BY CHKD DATE

BY: AEK A ECO-3631 DJ CT 02.02.90

CHKD: JDK B CF0171 PH 04.06.99

1. TEST CONDITIONS:

1.1. MAXIMUM PRESSURE REQUIRED: 2000 PSI

1.2. MAXIMUM FLOW REQUIRED: 8.5 GPM

6. CHECK SPOOL ACTION:

6.1. SPOOL MUST RETURN TO “NEUTRAL” FROM .19 “OUT” AND .19 “IN” UNDER ALL TEST CONDITIONS.

6.2. WITH SPOOL IN NEUTRAL, OIL MUST FLOW FREELY FROM INLET TO POWER BEYOND.

6.3. WITH BOOM CONNECTED TO PORT “B” AND SPOOL PULLED "OUT", BOOM MUST RAISE. RETURN SPOOL TO “NEUTRAL”, BOOM MUST

HOLD. PUSH SPOOL “IN”, BOOM MUST DROP.

6.4. WITH BOOM CONNECTED TO PORT “A” AND SPOOL PUSHED “IN”, BOOM MUST RAISE. RETURN SPOOL TO NEUTRAL, BOOM MUST HOLD.

PULL SPOOL “OUT”, BOOM MUST DROP.

Now I wanted to use this for the purpose of controlling a dual acting ram for my 3 point hitch top link, and then supplying pressure onto a logsplitter which uses a double acting ram and spool valve.

Nows here is my problem, I assumed that my spool the 1618-AL spool was neutral centre with the flow going straight through and connected it up as follows.

I used the method used by many on older B series tractor , I connected into the pressure line from the pump, took the pressure into the port marked “IN” then took the supply back to the rear 3pt hitch connection from the port marked “out”.

(same method I used on my b6000 with great success to power FEL etc)

I then fitted Q/R fittings to ports “A” & “B” ready for the ram.

Anyway, when I got the spool all the ports were open with 3/8 connectors fitted to the “in” & “OUT” and “PB” , the ports marked “A” &”B” just had plastic covers pushed in.

When I powered the system up there was a lot of squeeking coming from the spool , and appeared to be a lot of backpressure in the pressure line from the pump.

I tried the 3pt hitch which did work, but something doesn’t seem right and the noise is a bit concerning.

I bypassed the spool and removed it for further investigation, all is normal on the tractor now but I need to sort it out for the above useage.

I am no expert on this subject so any input would be really good to help me get it right.

Afterwards I was sent the specs from above which may be of help to assertain how I proceed.

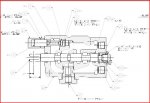

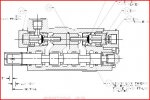

Also I have a diagram which I have attached a pic.

I think that maybe the config is different between the 1618 and the 1618AL , any help guys would be massive.

thanks

rob

I am adding extra hydraulic capacity to my B7100 , I already have the factory fitted hydraulic out from the rear 3pt spool for a single acting item , but, I want to keep it for my soon to be constructed tipping trailer so extra capacity is needed for my other items.

My question is this.

I have recently aquired a double acting single way spool valve made by”dukes fluid power” it’s a 1618AL.

It has the following ports , two ports marked “IN” & “OUT” on the front lower edge of the spool body, Two ports Marked “A” & “B” on the top of the spool body and a single port Marked “PB” on the side of the spool body.

Spec of valve:

DANFOSS FLUID POWER

ENGINEERING TEST ORDER

ETO# 156B2214

(was 1618-AL)

EASLEY OPERATION DATE: 01.06.88 REV CHANGE BY CHKD DATE

BY: AEK A ECO-3631 DJ CT 02.02.90

CHKD: JDK B CF0171 PH 04.06.99

1. TEST CONDITIONS:

1.1. MAXIMUM PRESSURE REQUIRED: 2000 PSI

1.2. MAXIMUM FLOW REQUIRED: 8.5 GPM

6. CHECK SPOOL ACTION:

6.1. SPOOL MUST RETURN TO “NEUTRAL” FROM .19 “OUT” AND .19 “IN” UNDER ALL TEST CONDITIONS.

6.2. WITH SPOOL IN NEUTRAL, OIL MUST FLOW FREELY FROM INLET TO POWER BEYOND.

6.3. WITH BOOM CONNECTED TO PORT “B” AND SPOOL PULLED "OUT", BOOM MUST RAISE. RETURN SPOOL TO “NEUTRAL”, BOOM MUST

HOLD. PUSH SPOOL “IN”, BOOM MUST DROP.

6.4. WITH BOOM CONNECTED TO PORT “A” AND SPOOL PUSHED “IN”, BOOM MUST RAISE. RETURN SPOOL TO NEUTRAL, BOOM MUST HOLD.

PULL SPOOL “OUT”, BOOM MUST DROP.

Now I wanted to use this for the purpose of controlling a dual acting ram for my 3 point hitch top link, and then supplying pressure onto a logsplitter which uses a double acting ram and spool valve.

Nows here is my problem, I assumed that my spool the 1618-AL spool was neutral centre with the flow going straight through and connected it up as follows.

I used the method used by many on older B series tractor , I connected into the pressure line from the pump, took the pressure into the port marked “IN” then took the supply back to the rear 3pt hitch connection from the port marked “out”.

(same method I used on my b6000 with great success to power FEL etc)

I then fitted Q/R fittings to ports “A” & “B” ready for the ram.

Anyway, when I got the spool all the ports were open with 3/8 connectors fitted to the “in” & “OUT” and “PB” , the ports marked “A” &”B” just had plastic covers pushed in.

When I powered the system up there was a lot of squeeking coming from the spool , and appeared to be a lot of backpressure in the pressure line from the pump.

I tried the 3pt hitch which did work, but something doesn’t seem right and the noise is a bit concerning.

I bypassed the spool and removed it for further investigation, all is normal on the tractor now but I need to sort it out for the above useage.

I am no expert on this subject so any input would be really good to help me get it right.

Afterwards I was sent the specs from above which may be of help to assertain how I proceed.

Also I have a diagram which I have attached a pic.

I think that maybe the config is different between the 1618 and the 1618AL , any help guys would be massive.

thanks

rob

Attachments

-

54.7 KB Views: 418

-

40.8 KB Views: 365

-

65.2 KB Views: 396

-

17.9 KB Views: 346

Last edited: