I have only owned this tractor for about a month so still figuring it out.

After using the tractor for about 1 hour today, I noticed there was a slow oil leak dripping on the ground under the hydrostatic transmission. I can't exactly tell where it is coming from though. It seems to be where the hydraulic transmission is joined to the rear diff?

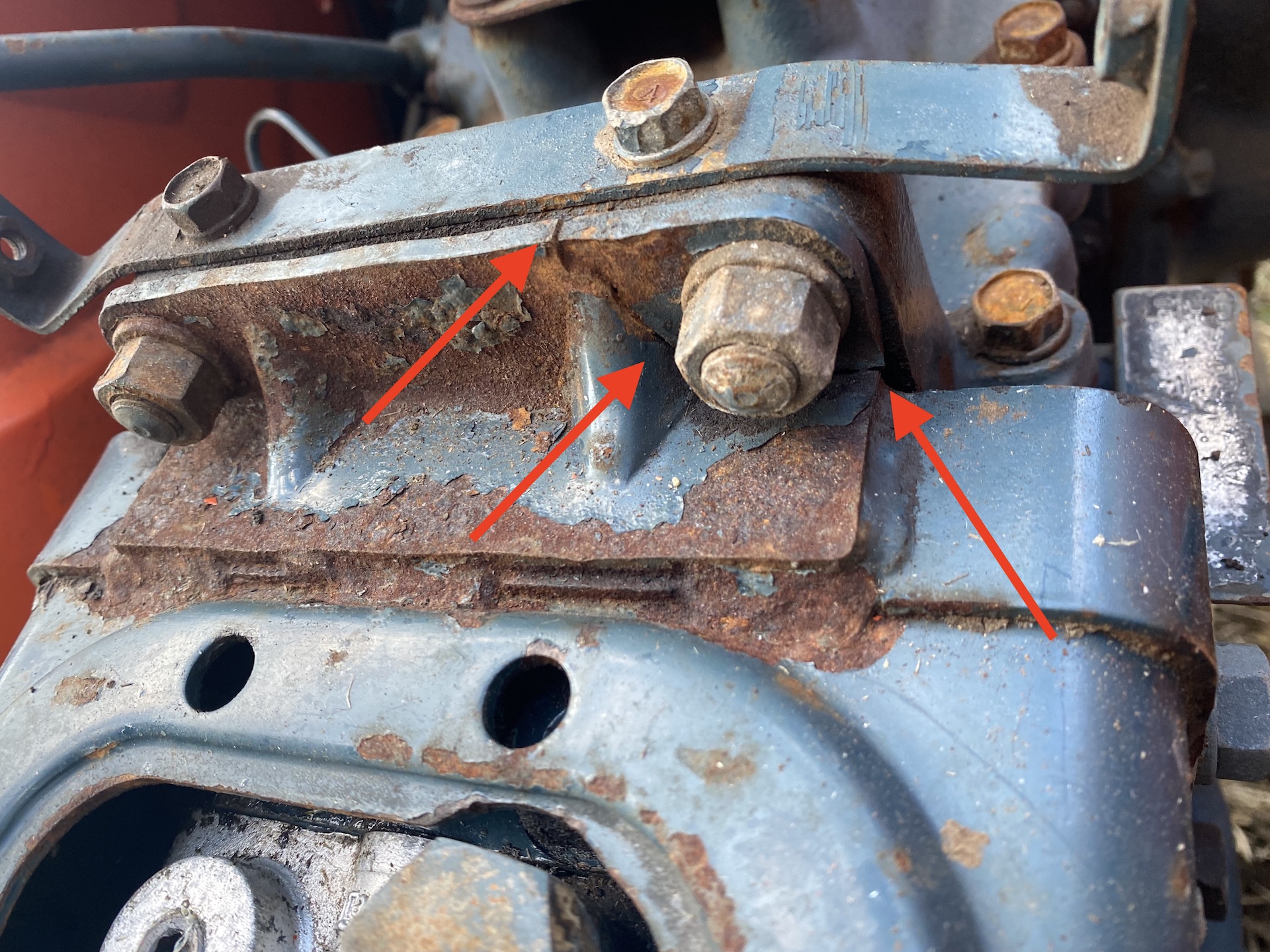

It is on both the left and right side of the clutch housing which encases the HST by the looks of things? It is hard to actually see the HST inside the clutch housing.

Oil leak right side

Oil Leak left side

The only thing I could find was a crack around this bolt at the top. Not sure if that is causing the leak though.

The HST and clutch hosing was a bit warm, I am not sure if that is normal?

The only other thing I can think of is the front drive shaft wobbling is somehow causing the HST to leak. I posted about the front drive shaft here.

Does anyone know where the leak would be coming from or how I can investigate further?

After using the tractor for about 1 hour today, I noticed there was a slow oil leak dripping on the ground under the hydrostatic transmission. I can't exactly tell where it is coming from though. It seems to be where the hydraulic transmission is joined to the rear diff?

It is on both the left and right side of the clutch housing which encases the HST by the looks of things? It is hard to actually see the HST inside the clutch housing.

Oil leak right side

Oil Leak left side

The only thing I could find was a crack around this bolt at the top. Not sure if that is causing the leak though.

The HST and clutch hosing was a bit warm, I am not sure if that is normal?

The only other thing I can think of is the front drive shaft wobbling is somehow causing the HST to leak. I posted about the front drive shaft here.

Does anyone know where the leak would be coming from or how I can investigate further?