I have been lurking here for a few months and figured it was time to contribute. Its been years since i have been on a forum, almost feels like using a chatroom again.

I picked up my B6100D in December and what started out as some fixing up has turned into a rebuild. My garage isn't really equipped but I've been itching for a project for years. I was a C-130 aircraft mechanic for 13 years and used to love doing the heavy maintenance on it. 5 years, 4 kids, a bad back and a career change to the IT world and i'm ready to get my hands dirty.

I picked up my B6100D in December and what started out as some fixing up has turned into a rebuild. My garage isn't really equipped but I've been itching for a project for years. I was a C-130 aircraft mechanic for 13 years and used to love doing the heavy maintenance on it. 5 years, 4 kids, a bad back and a career change to the IT world and i'm ready to get my hands dirty.

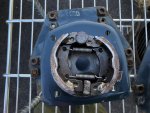

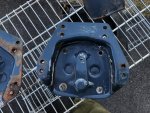

Attachments

-

95.2 KB Views: 325

-

106.2 KB Views: 322

-

104.4 KB Views: 322

-

90.2 KB Views: 326

-

95.7 KB Views: 330