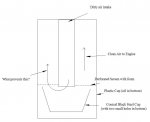

I disassembled my air breather tonight to change the oil in it. While assembling it, I realized that the air breather does not make sense to me. In my opinion, it does not force the dirty air to go through the oil. The dirty air is free to go into the engine. I've attached a schematic of what I think can happen.

Several questions:

1) Is the black, conical, steel cup supposed to touch the dirty air intake tube?

2) Is the black conical, steel cup supposed to touch the perforated screen with foam?

In my case, the answer to question 1 is definitely not. The answer to question 2 is that it is close. Perhaps an 1/8" to 1/4" away.

More questions:

3) The manual mentions to fill with oil up to the indicated level. I can find no mark to indicate how high to fill with oil. There was about 1" in the bottom of the plastic cup when I took possession of it.

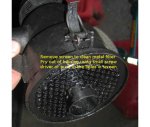

4) Does the perforated metal screen with foam come out? If so, how do you remove? Fortunately, this foam appears to be saturated with oil, and I suspect this has been preventing most of the dirt from entering the engine. If it can't be removed, I imagine I will soak the whole assembly in gasoline.

5) In the parts manual, it mentions Item 20, Part No 10283-11210. I'm not certain I have that piece. It may be wedged up there with the metal screen I can't remove. I've also noted the plastic bowl doesn't seem to quite "mate up" with the metal parts as well as I would expect. It's close - but I'm wonder if perhaps this part got exchanged with the wrong part.

I have attached a couple pictures of my assembly in hopes that you will spot something I don't.

Thank you,

Chris

Several questions:

1) Is the black, conical, steel cup supposed to touch the dirty air intake tube?

2) Is the black conical, steel cup supposed to touch the perforated screen with foam?

In my case, the answer to question 1 is definitely not. The answer to question 2 is that it is close. Perhaps an 1/8" to 1/4" away.

More questions:

3) The manual mentions to fill with oil up to the indicated level. I can find no mark to indicate how high to fill with oil. There was about 1" in the bottom of the plastic cup when I took possession of it.

4) Does the perforated metal screen with foam come out? If so, how do you remove? Fortunately, this foam appears to be saturated with oil, and I suspect this has been preventing most of the dirt from entering the engine. If it can't be removed, I imagine I will soak the whole assembly in gasoline.

5) In the parts manual, it mentions Item 20, Part No 10283-11210. I'm not certain I have that piece. It may be wedged up there with the metal screen I can't remove. I've also noted the plastic bowl doesn't seem to quite "mate up" with the metal parts as well as I would expect. It's close - but I'm wonder if perhaps this part got exchanged with the wrong part.

I have attached a couple pictures of my assembly in hopes that you will spot something I don't.

Thank you,

Chris

Attachments

-

27.2 KB Views: 1,373

-

85.9 KB Views: 4,063

-

87 KB Views: 3,817