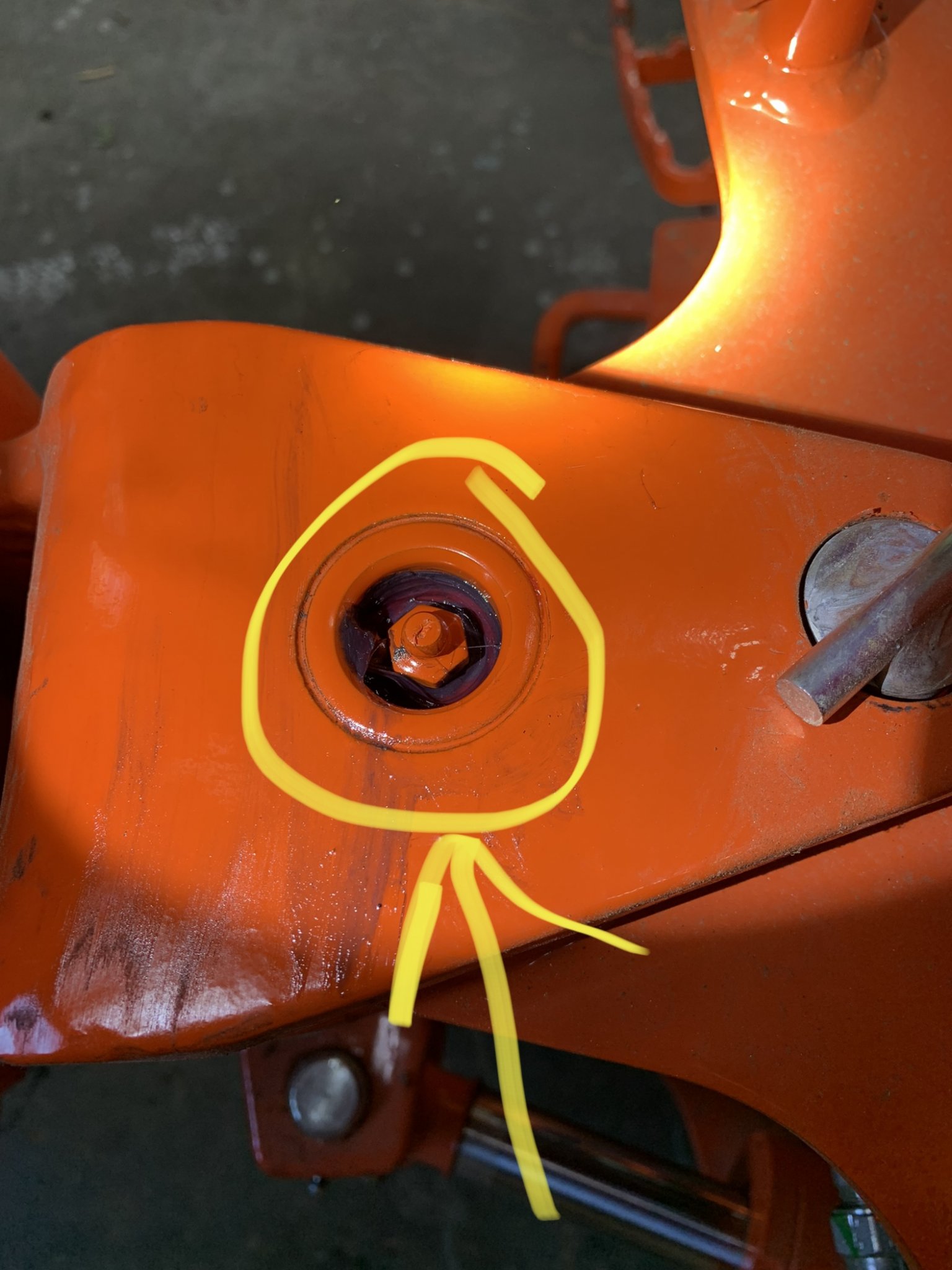

I have a 2021 bx23s, I was doing the 10hr greasing and when I got to where the backhoe pivots, the zerk looks like it’s painted over. But there’s grease all around it like the guy from the dealership greased it before it was delivered. I don’t know if I should worry about this or not?

I tried scoring it with a pocket knife but it seems like it’s a fake zerk fitting?

I tried scoring it with a pocket knife but it seems like it’s a fake zerk fitting?