Tomorrow I have been asked by a friend for help with his TG1860 diesel.

He has been experiencing a strong vibration with only the motor running and has concluded something is amiss in the driveshaft from the engine to the bevel gear box at the rear of the tractor.

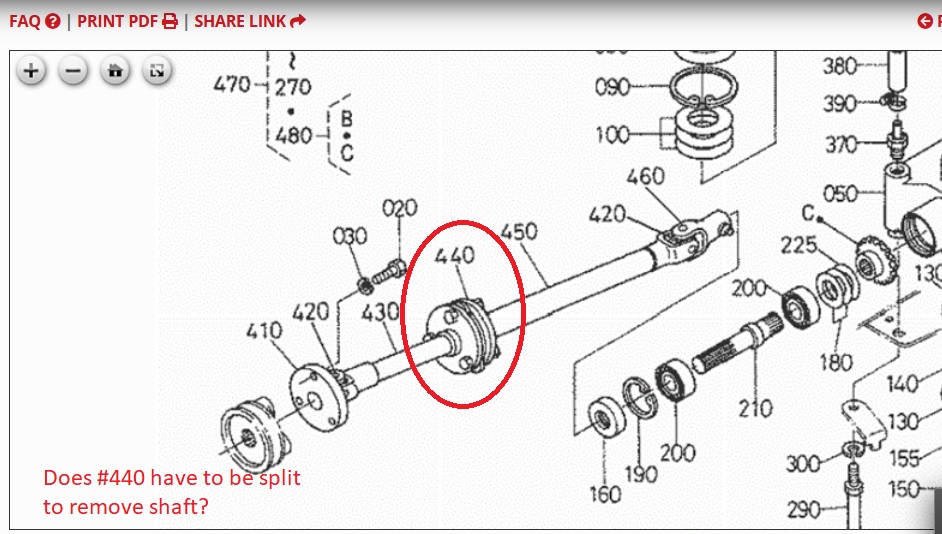

He says he has the driveshaft loose at the motor end but cannot figure out how to pull the shaft from under the machine. The mower deck is still in place. The engine end of the shaft is a circular piece (#410) and seems to big to slide out.

Any advice on driveshaft removal on this model would be appreciated.

Dave

He has been experiencing a strong vibration with only the motor running and has concluded something is amiss in the driveshaft from the engine to the bevel gear box at the rear of the tractor.

He says he has the driveshaft loose at the motor end but cannot figure out how to pull the shaft from under the machine. The mower deck is still in place. The engine end of the shaft is a circular piece (#410) and seems to big to slide out.

Any advice on driveshaft removal on this model would be appreciated.

Dave