Was moving the trailer around with chain from the bucket and decided That there is just too much swing and it might be a little too hard on some of the light metal on the trailer and I need a trailer hit h for the front. I don't want to have to take off implements from the rear to put on a trailer hitch. I'm looking to have a trailer hitch that mounts to the front. I considered drilling a hole through the bucket so I can just bolt a 2 inch ball to it but I don't like the idea of drilling a hole in the bucket if I don't have to. I'm debating as to whether or not I would like to fabricate a bolt on or pin on hitch that can use the case weight holes that are on the front bumper/grill. My question is... Does anyone have any experience using that front bumper/grill as an attachment point for a hitch and what thickness of metal should I be using to bolt to it. Your opinions are appreciated.

Question about building a front hitch for the l3800

- Thread starter IDKUBOTA

- Start date

A clamp on receiver for the FEL would be my choice, and what I plan to make (when the temps drop a more into double digits). I've seen them permanently added, but it seems to me that would interfere with other common bucket operations, though probably not as much as I imagine. Using the FEL bucket also makes it easy to pick it up without having to necessarily screw with the jack, or to maybe dip it down to slip the trailer back edge over an slab edge or something.

Burt

New member

Equipment

L3700SU, box blade, 6 foot rhino blade, 1 bottom plow, 3 point receiver hitch.

Number9:

I purchased a hitch receiver from Harbor freight and a 2" ball for it. Drilled holes for the receiver hitch dead center. Now, I just slide in the ball into the receiver when I want to move our RV trailer. It's much easier than trying to back it into a building and very quick.

Lots of tractor owners weld these on but I like to be able to remove it if I needed to. To fill the hole if removing it, just plug it with fender washers, gum pucky it up and bolt it shut.

This idea came to me after seeing a neighbor's L275 done the same way. He moves a very large boat in and out of his shed using the same method. He also moves other large equipment around the same way.

Good luck on your choice.

Burt

I purchased a hitch receiver from Harbor freight and a 2" ball for it. Drilled holes for the receiver hitch dead center. Now, I just slide in the ball into the receiver when I want to move our RV trailer. It's much easier than trying to back it into a building and very quick.

Lots of tractor owners weld these on but I like to be able to remove it if I needed to. To fill the hole if removing it, just plug it with fender washers, gum pucky it up and bolt it shut.

This idea came to me after seeing a neighbor's L275 done the same way. He moves a very large boat in and out of his shed using the same method. He also moves other large equipment around the same way.

Good luck on your choice.

Burt

I have a 3200 with a quick bucket. I purchased a blank skid loader attachment plate and a 2" hitch receiver stock. I cut a hole in the center of the plate and welded the stock in place. This way its nice and tight to the tractor and won't allow much play. Hope this helps. EBay is a useful tool too.

thanks for the advice and ideas. We are going to build a bolt on hitch that bots on in two places and span at least 1/2 the length of the bucket to limit side to side movement. We will incorporate the underside lip of the bucket to fit firmly in the bolt on attachment. I'll have pictures when completed. I did see that ebay has a "titan" clamp on bucket hitch for about $90 delivered. I think that we can build ours for about $20 and all the other components are in the barn.

IDK

IDK

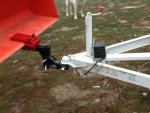

Well, the FEL trailer hitch is complete. My uncle put it together for me out of scrap (although at 1$/lb from the recycler it doesn't feel like scrap). The design changed a little from what was thought originally. 3 pieces of plate steel welded together(top and bottom with a spacer), a small welded rod to provide support at the bevel of the cutting edge of the bucket, plate attached to the lower plate which grabs the rear lower cutting edge to limit ANY side to side movement, and the hollow tube welded to the lower plate. The bolts do not touch the bucket and are in the front of the bucket so as not to gouge the bucket metal and serve to clamp the unit to the bucket super tight. Not the prettiest tool I have but at $41 for the steel, it was cheaper than what was available on eBay and a much stronger attachment, thanks to my Uncle G and his welder. Works like a charm. My uncle liked the outcome so much he is going to make one for himself.

For what it is worth, if anyone is interested, I will add a picture of my uncles power hack saw which his father G-Uncle Benny built 40+ years ago. It made cutting through 5 inch wide 3/4" thickness plate steel pretty easy. It took about 45 minutes but no shoulders were aching when the cutting was complete.

Thanks for your input. I appreciate it. Cheers,

IDK

For what it is worth, if anyone is interested, I will add a picture of my uncles power hack saw which his father G-Uncle Benny built 40+ years ago. It made cutting through 5 inch wide 3/4" thickness plate steel pretty easy. It took about 45 minutes but no shoulders were aching when the cutting was complete.

Thanks for your input. I appreciate it. Cheers,

IDK

Attachments

-

54.4 KB Views: 552

-

84.2 KB Views: 553

-

53.5 KB Views: 539

Last edited:

gpreuss

New member

Lifetime Member

Equipment

L3200DT w/FEL, K650 Backhoe, 5' Rotary, 40" Howard Rotavator, 6' Rhino blade

The only thing I don't like about having my hitch down low is you can't see it, does that deep drop ball mount allow you to see under the bucket when hitching up?

Sent from my DROID RAZR using Tapatalk 2

Sent from my DROID RAZR using Tapatalk 2

Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

Here's mine, just labor, everything else was lying around the shop:

Attachments

-

55.9 KB Views: 256

-

72.6 KB Views: 250

-

46.6 KB Views: 261

-

28.3 KB Views: 244