Background

I have and old Ransomes 213d highway mower that I use as a backup from time to time. It's powered by a Kubota d950 3 cylinder. I inherited the machine about 10 years ago and it's been fairly reliable albeit very hard to start and smoked like hell for the first 5 minutes of use.

This year it started smoking quite bad all the time (white smoke) and the engine sounded rough so we stopped using it.

I did a compression test on each cylinder and they all read approximately 150 psi. This doubled when I dropped a spoonful of oil on the cylinders so my assumption after much research (I'm a novice btw) that it was probably the rings.

So I pulled the head and that looked fine with no signs of obvious damage. The piston heads also looked in good shape although I did notice that piston 2 did not quite travel to TDC like 1 & 3.

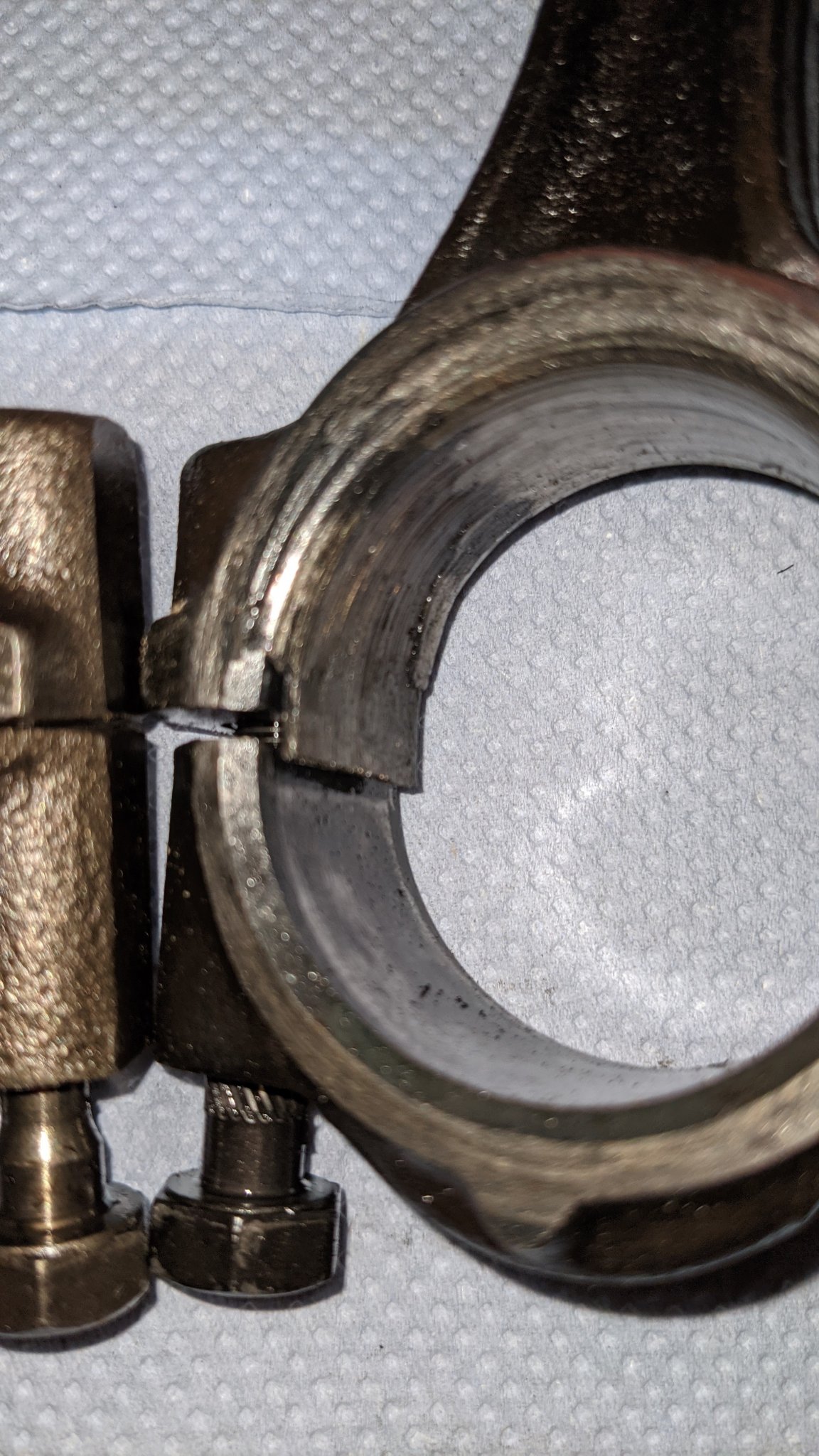

I then proceeded to extract the pistons and immediately saw that piston 2 top ring was broken and the connecting rod bearing was also damaged (see second image)

What puzzled me was that the rod on piston 2 looked bent (see red arrow below) and i'm not sure if this is a fault or buy design? It certainly would explain why it didn't travel to TDC.

Piston's 1 & 3 are stamped with the letter ("I") and piston 2 is stamped with the letter ("M"). The bolts are also of a different specification which you can just about make out in the second image that shows the damaged bearing.

So is piston 2 shot or is this how it should be ? I can't see anything obvious in the WSM or parts manuals.

Pistons (3,2,1). Note The rods on 3 & 1 are straight - although the picture angle makes 1 look out.

Bearing damage to piston 2. Note the bolts are a different specification.

I have and old Ransomes 213d highway mower that I use as a backup from time to time. It's powered by a Kubota d950 3 cylinder. I inherited the machine about 10 years ago and it's been fairly reliable albeit very hard to start and smoked like hell for the first 5 minutes of use.

This year it started smoking quite bad all the time (white smoke) and the engine sounded rough so we stopped using it.

I did a compression test on each cylinder and they all read approximately 150 psi. This doubled when I dropped a spoonful of oil on the cylinders so my assumption after much research (I'm a novice btw) that it was probably the rings.

So I pulled the head and that looked fine with no signs of obvious damage. The piston heads also looked in good shape although I did notice that piston 2 did not quite travel to TDC like 1 & 3.

I then proceeded to extract the pistons and immediately saw that piston 2 top ring was broken and the connecting rod bearing was also damaged (see second image)

What puzzled me was that the rod on piston 2 looked bent (see red arrow below) and i'm not sure if this is a fault or buy design? It certainly would explain why it didn't travel to TDC.

Piston's 1 & 3 are stamped with the letter ("I") and piston 2 is stamped with the letter ("M"). The bolts are also of a different specification which you can just about make out in the second image that shows the damaged bearing.

So is piston 2 shot or is this how it should be ? I can't see anything obvious in the WSM or parts manuals.

Pistons (3,2,1). Note The rods on 3 & 1 are straight - although the picture angle makes 1 look out.

Bearing damage to piston 2. Note the bolts are a different specification.