I hope this is going in the correct forum. If not I'm sorry Mr.K

When I purchased my tractor (B7610) five years ago I wanted to add extra lights. So I did, on the ROPS like most everybody else.

I drew up a wire diagram and tapped power off of the stock work light fuse. It's located under the left removable engine cover towards the back and is stock OEM at 20 amps.

I decided to place all of the main circuitry in the useless tool box that is located under the drivers seat.

The lights are attached to metal bars that are fastened to the ROPS with squared U-bolts. The U-bolts are covered in heat shrink to keep from causing metal to metal problems.

I drew the diagram for my tractor but obviously it will work for just about anything that generates power. Just tweek the amperage as needed, up or down.

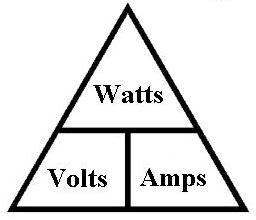

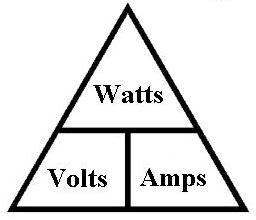

Just rember Ohm's Law:

If you know any of the two you can calculate the third.

For instance: 1 Lamp is 55 watts and 12V DC. 55 devided by 12 = 4.58. Round up to 4.6 amps. Easy!

I hope this information will be of use for people looking for lighting options and posabilities.

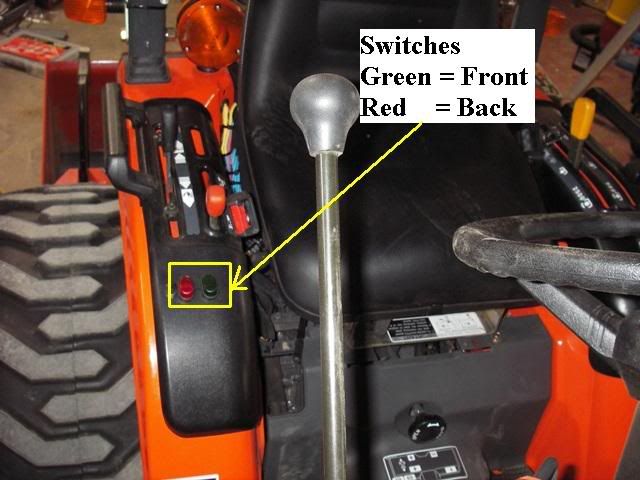

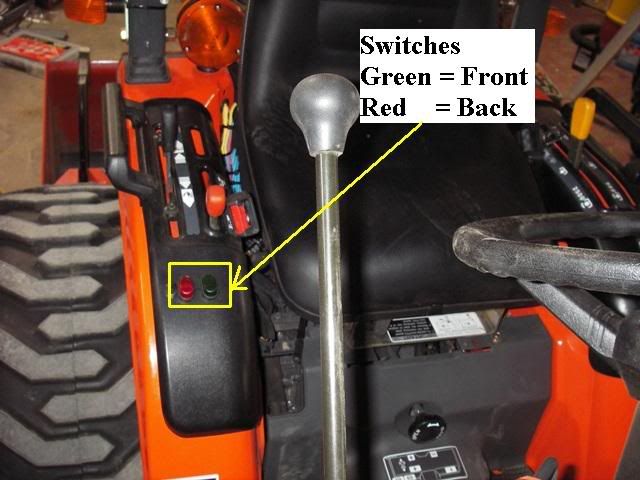

The pictures are self explanatory but if there are any questions please ask.

Any criticism is also welcome

Scott

When I purchased my tractor (B7610) five years ago I wanted to add extra lights. So I did, on the ROPS like most everybody else.

I drew up a wire diagram and tapped power off of the stock work light fuse. It's located under the left removable engine cover towards the back and is stock OEM at 20 amps.

I decided to place all of the main circuitry in the useless tool box that is located under the drivers seat.

The lights are attached to metal bars that are fastened to the ROPS with squared U-bolts. The U-bolts are covered in heat shrink to keep from causing metal to metal problems.

I drew the diagram for my tractor but obviously it will work for just about anything that generates power. Just tweek the amperage as needed, up or down.

Just rember Ohm's Law:

If you know any of the two you can calculate the third.

For instance: 1 Lamp is 55 watts and 12V DC. 55 devided by 12 = 4.58. Round up to 4.6 amps. Easy!

I hope this information will be of use for people looking for lighting options and posabilities.

The pictures are self explanatory but if there are any questions please ask.

Any criticism is also welcome

Scott

Last edited: