Hi from Australia,

I have an issue with my old L245DT kubota.

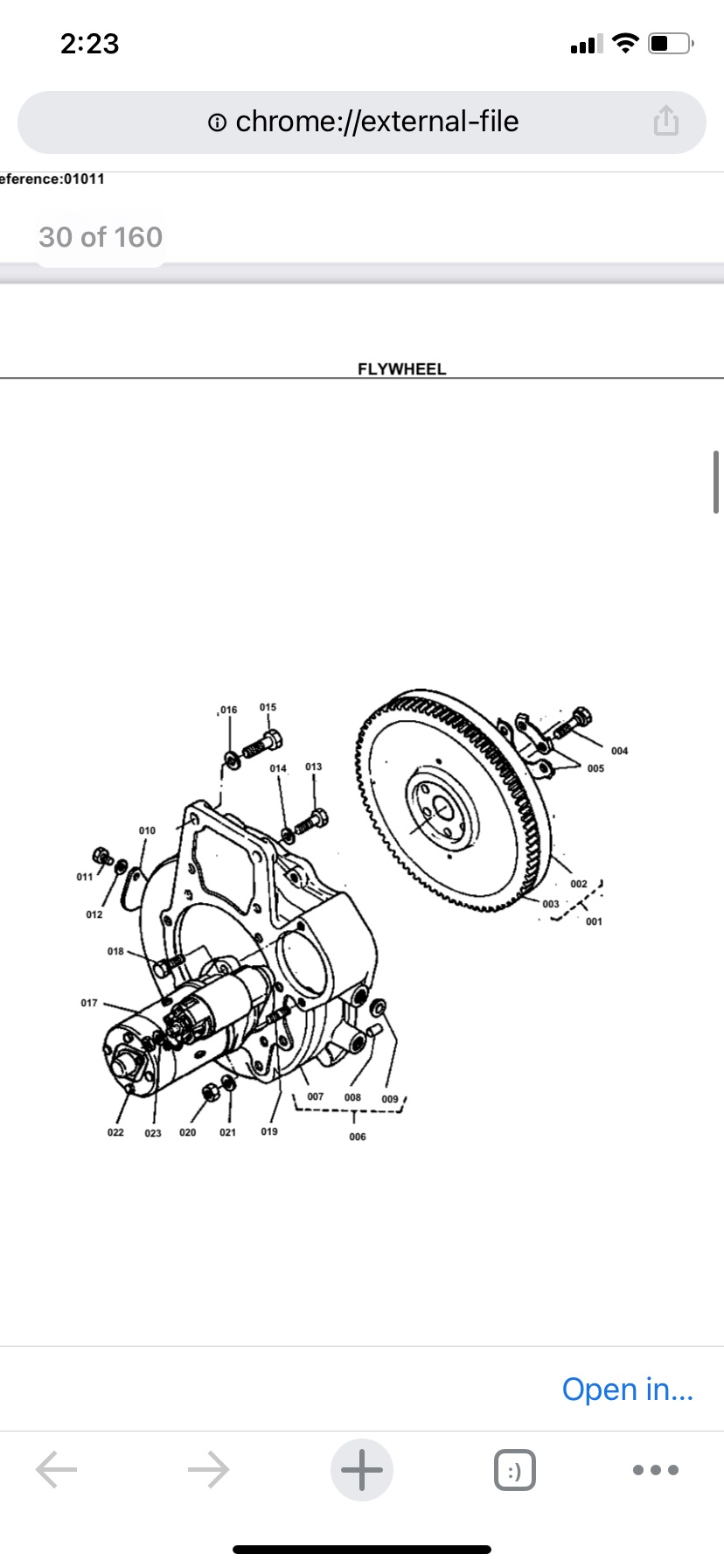

My issues began with very weak hydraulics and basically straight after this a plastic plug blew out of the bellhousing and sprayed a jet of gear oil all over my steep driveway. I lost 5-8 litres in a short period of time. When I shut the engine down the high pressure disappeared. The plug that came out is labeled number 8 on the diagram.

I thought it was unusual to have oil in the bellhousing and thought that maybe it was a wet clutch model. I plugged the hole and drained the transmission/cleaned the filter screen (it was filthy) and topped up the oil with UTTO. Which was quiet a lot thinner than the oil that came out. ( not sure if this caused further issues with clutch slipping)

I thought it was unusual to have oil in the bellhousing and thought that maybe it was a wet clutch model. I plugged the hole and drained the transmission/cleaned the filter screen (it was filthy) and topped up the oil with UTTO. Which was quiet a lot thinner than the oil that came out. ( not sure if this caused further issues with clutch slipping)

I decided to try and do some slashing and instantly noticed that the clutch was slipping in high range especially on hills. Low range was okay.

Hydraulics still werent the best either and my front end loader was hardly lifting.

I am confident that it’s not engine oil causing the slipping because the level is consistent and the oil was cold and cleaner than engine oil

Not sure if I have overfilled the transmission at some point which has traveled into the bellhousing on my steep property or if I have a serious leak in a transmission seal. I have searched the forums and can’t really find to much info.

I opened up the clutch inspection port which was filled with at least 5 litres of oil, up to the inspection port holes. I drained and degreased what I could.

I decided to change the transmission oil with a thicker oil. During 10minutes of running the tractor the filter screen was blocked up again pretty badly. This time it wasn’t metal and I was thinking it may have been clutch material or a seal. The oil was very dark and contaminated already as well. Not sure what is going on!

When refilling, by the time I hit the fill level I could see another 5 litres in the bellhousing and it was leaking out of the inspection point again.

I’m really hoping that I’m simply overfilling the gearbox and it’s somehow finding it’s way into the bellhousing. On the left hand side there are two bolts that I had loose during filling and stopped somewhere between the two. I found a bellhousing drain plug which I’m thinking I might leave out for a bit to see if it’s a continual leak or if it’s from overfilling.

I really haven’t got the time to split the tractor for a while as I am about to have another cub and won’t have the cash for a clutch replacement.

Has anyone got any ideas?

Could it be a blocked vent or hydraulic relief valve?

If it is a transmission seal has anyone done this job or are they instructions in the manual.

See pics of inspection port, dirty oil and a diagram of the plug that came out.

Thanks in advance for all your help. This is an awesome resource.

I have an issue with my old L245DT kubota.

My issues began with very weak hydraulics and basically straight after this a plastic plug blew out of the bellhousing and sprayed a jet of gear oil all over my steep driveway. I lost 5-8 litres in a short period of time. When I shut the engine down the high pressure disappeared. The plug that came out is labeled number 8 on the diagram.

I decided to try and do some slashing and instantly noticed that the clutch was slipping in high range especially on hills. Low range was okay.

Hydraulics still werent the best either and my front end loader was hardly lifting.

I am confident that it’s not engine oil causing the slipping because the level is consistent and the oil was cold and cleaner than engine oil

Not sure if I have overfilled the transmission at some point which has traveled into the bellhousing on my steep property or if I have a serious leak in a transmission seal. I have searched the forums and can’t really find to much info.

I opened up the clutch inspection port which was filled with at least 5 litres of oil, up to the inspection port holes. I drained and degreased what I could.

I decided to change the transmission oil with a thicker oil. During 10minutes of running the tractor the filter screen was blocked up again pretty badly. This time it wasn’t metal and I was thinking it may have been clutch material or a seal. The oil was very dark and contaminated already as well. Not sure what is going on!

When refilling, by the time I hit the fill level I could see another 5 litres in the bellhousing and it was leaking out of the inspection point again.

I’m really hoping that I’m simply overfilling the gearbox and it’s somehow finding it’s way into the bellhousing. On the left hand side there are two bolts that I had loose during filling and stopped somewhere between the two. I found a bellhousing drain plug which I’m thinking I might leave out for a bit to see if it’s a continual leak or if it’s from overfilling.

I really haven’t got the time to split the tractor for a while as I am about to have another cub and won’t have the cash for a clutch replacement.

Has anyone got any ideas?

Could it be a blocked vent or hydraulic relief valve?

If it is a transmission seal has anyone done this job or are they instructions in the manual.

See pics of inspection port, dirty oil and a diagram of the plug that came out.

Thanks in advance for all your help. This is an awesome resource.