Hi! A short introduction: I've lived my whole life on a farm in Auckland, New Zealand surrounded with tractors. Mostly old David Browns at this point but also a couple of Kubota's. I'm not really experienced with fixing tractors but I've done some basic work on them before including repairing electrical stuff. I've also rebuilt a mower engine before.

On the farm there is an old Kubota B6000. It's one of the first tractors I ever drove. It's also the first tractor I ever worked on, repairing the fuel line and later the electrics. I often used it for towing trailers or moving heavy items. I love how small but capable it is and it's my favourite tractor. It worked pretty well but had a few issues like a hard to move throttle. Several years ago the steering completely stopped working. It's been left out and has unfortunately deteriorated a lot recently.

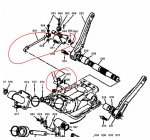

About a year ago I had another look at the steering and tried welding new teeth onto the sector gear as they were worn in the shape of the worm gear. It worked for just a short while but then stopped again. The teeth weren't even engaging with the worm gear.

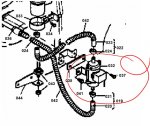

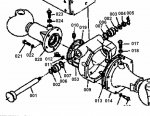

Just recently I've been looking at the tractor again and this time I've found the parts, service and operating manuals as well as this forum and some youtube videos. The steering assembly is the "old style". I can see now that the problem with the steering was that there were no bearings (actually I found about 2 balls from the lower bearing when cleaning it). I had assumed the worm gear was held in the correct place with bearings in the outer shaft cover but actually the shaft had been rubbing against the edge of the upper bearing race and oil seal, grinding a lot of it away.

Getting the bottom race out of the steering box was difficult. I first used penetrant and tried to lever it out or bang a screwdriver around the edges. I then heated the case up with my hot air gun - I'm not sure that made a difference. - then I managed to get the race out by knocking on the base of the case with a hammer.

I removed the two oils seals by banging a screwdriver in around the edge then using it to bend the metals outer ring of the seals in and lever them out. Below is the original sector gear shaft oil seal. It reads AE1245E 24 - 35 8.

The tractor is technically not mine and I'm not sure it will stay around for me to use so I'm not wanting to put too much money into fixing it.

Today I went to Bearing Supplies and bought a new upper and lower bearing, oil seals, loose balls, and RTV silicone gasket maker and then I went to Waitemata Hydraulics and Mitre 10 for some washers, a rubber plug, some bolts and circlips.

The upper bearing (66591-41140) is 40mm x ~17mm x 11mm. The following seem to be equivalent:

ACS0304

VBT17Z-3

The lower bearing (66591-41130) is 35mm x 15mm x 11mm with the following equivalent items:

ACS0304-2

VBT15Z-2

15BSW02

The two bearings I bought are ACS0304 and 15BSW02. About $20 NZD each. They don't feel very smooth against the races on the steering shaft but the shaft is rusted and pitted. I think it will be OK.

The oil seals are 32mm x ~17mm x 8mm for the steering shaft seal above the top bearing and 35mm x 24mm x 8mm for the sector gear shaft seal. The model numbers of the parts I got were TC12419 (17-32-7), TC12413 (16-32-7, in case it fits better for the rusted steering shaft) and TC12455 (24-35-7). All about $3.50 each. Note they are only 7mm thick instead of 8mm but I don't think it matters much.

The bolts I got were flange head Grade 8.8 M8 yellow zinc coated at lengths of 16 and 20mm. I think they are standard(course)/JIS thread pitch at 1.25mm but I'll have to check. Mitre 10 SKUs 225886/7.

I lost the original circlip (04611-00190) that holds the adjusting screw in the sector gear shaft. I bought 18 and 20mm internal circlips, I think 20mm should be correct. The single large ball bearing (07715-01605) appears to be 5/16 and the 20 smaller balls (07715-03203) appear to be 3/32. Do you think that sounds correct as opposed to being metric sizes like 8mm and 2.3mm? They didn't have the smaller size in stock at Bearing Supplies so I got some 2.5mm bearings to try, otherwise I can use the original ones.

I bought a rubber plug to replace part 61011-18142 that fits into the end of the adjusting screw nut. The part is Stopper Rubber Small #00 (SKU 337552) for $2 at Mitre 10.

I installed the lower bearing race and made a quick assembly tonight but it seems the sector gear I built up with welding is now a bit too big and I'll need to grind the teeth down.

The tractor has a whole lot of other issues and I'll update this thread as I continue fixing the steering and other issues. I'll also post some more photos soon.

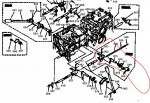

B6000 Parts book

B6000 Operators manual

B6000 Service manual

The parts book is also available online here: https://kubota.co.nz/part/parts-catalogue/

On the farm there is an old Kubota B6000. It's one of the first tractors I ever drove. It's also the first tractor I ever worked on, repairing the fuel line and later the electrics. I often used it for towing trailers or moving heavy items. I love how small but capable it is and it's my favourite tractor. It worked pretty well but had a few issues like a hard to move throttle. Several years ago the steering completely stopped working. It's been left out and has unfortunately deteriorated a lot recently.

About a year ago I had another look at the steering and tried welding new teeth onto the sector gear as they were worn in the shape of the worm gear. It worked for just a short while but then stopped again. The teeth weren't even engaging with the worm gear.

Just recently I've been looking at the tractor again and this time I've found the parts, service and operating manuals as well as this forum and some youtube videos. The steering assembly is the "old style". I can see now that the problem with the steering was that there were no bearings (actually I found about 2 balls from the lower bearing when cleaning it). I had assumed the worm gear was held in the correct place with bearings in the outer shaft cover but actually the shaft had been rubbing against the edge of the upper bearing race and oil seal, grinding a lot of it away.

Getting the bottom race out of the steering box was difficult. I first used penetrant and tried to lever it out or bang a screwdriver around the edges. I then heated the case up with my hot air gun - I'm not sure that made a difference. - then I managed to get the race out by knocking on the base of the case with a hammer.

I removed the two oils seals by banging a screwdriver in around the edge then using it to bend the metals outer ring of the seals in and lever them out. Below is the original sector gear shaft oil seal. It reads AE1245E 24 - 35 8.

The tractor is technically not mine and I'm not sure it will stay around for me to use so I'm not wanting to put too much money into fixing it.

Today I went to Bearing Supplies and bought a new upper and lower bearing, oil seals, loose balls, and RTV silicone gasket maker and then I went to Waitemata Hydraulics and Mitre 10 for some washers, a rubber plug, some bolts and circlips.

The upper bearing (66591-41140) is 40mm x ~17mm x 11mm. The following seem to be equivalent:

ACS0304

VBT17Z-3

The lower bearing (66591-41130) is 35mm x 15mm x 11mm with the following equivalent items:

ACS0304-2

VBT15Z-2

15BSW02

The two bearings I bought are ACS0304 and 15BSW02. About $20 NZD each. They don't feel very smooth against the races on the steering shaft but the shaft is rusted and pitted. I think it will be OK.

The oil seals are 32mm x ~17mm x 8mm for the steering shaft seal above the top bearing and 35mm x 24mm x 8mm for the sector gear shaft seal. The model numbers of the parts I got were TC12419 (17-32-7), TC12413 (16-32-7, in case it fits better for the rusted steering shaft) and TC12455 (24-35-7). All about $3.50 each. Note they are only 7mm thick instead of 8mm but I don't think it matters much.

The bolts I got were flange head Grade 8.8 M8 yellow zinc coated at lengths of 16 and 20mm. I think they are standard(course)/JIS thread pitch at 1.25mm but I'll have to check. Mitre 10 SKUs 225886/7.

I lost the original circlip (04611-00190) that holds the adjusting screw in the sector gear shaft. I bought 18 and 20mm internal circlips, I think 20mm should be correct. The single large ball bearing (07715-01605) appears to be 5/16 and the 20 smaller balls (07715-03203) appear to be 3/32. Do you think that sounds correct as opposed to being metric sizes like 8mm and 2.3mm? They didn't have the smaller size in stock at Bearing Supplies so I got some 2.5mm bearings to try, otherwise I can use the original ones.

I bought a rubber plug to replace part 61011-18142 that fits into the end of the adjusting screw nut. The part is Stopper Rubber Small #00 (SKU 337552) for $2 at Mitre 10.

I installed the lower bearing race and made a quick assembly tonight but it seems the sector gear I built up with welding is now a bit too big and I'll need to grind the teeth down.

The tractor has a whole lot of other issues and I'll update this thread as I continue fixing the steering and other issues. I'll also post some more photos soon.

B6000 Parts book

B6000 Operators manual

B6000 Service manual

The parts book is also available online here: https://kubota.co.nz/part/parts-catalogue/

Last edited: