Hi all new member here New Zealand based.

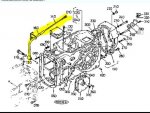

My M4950(year unknown) decided to shear the driving shaft of the hydraulic pump.

Been trying to find what caused it and so far cavitation seems plausible.

Had fel on it but I took it off while working on

How do I check the hydraulic oil level?

What if the entire dipstick arrangement is not there?(140,150,160,170,180) Couldn't tell year of old rusty I'm sorry,you'll understand when you see her.

Any help is appreciated. Cheerzzz...

My M4950(year unknown) decided to shear the driving shaft of the hydraulic pump.

Been trying to find what caused it and so far cavitation seems plausible.

Had fel on it but I took it off while working on

How do I check the hydraulic oil level?

What if the entire dipstick arrangement is not there?(140,150,160,170,180) Couldn't tell year of old rusty I'm sorry,you'll understand when you see her.

Any help is appreciated. Cheerzzz...

Attachments

-

141.4 KB Views: 111

-

240.7 KB Views: 90