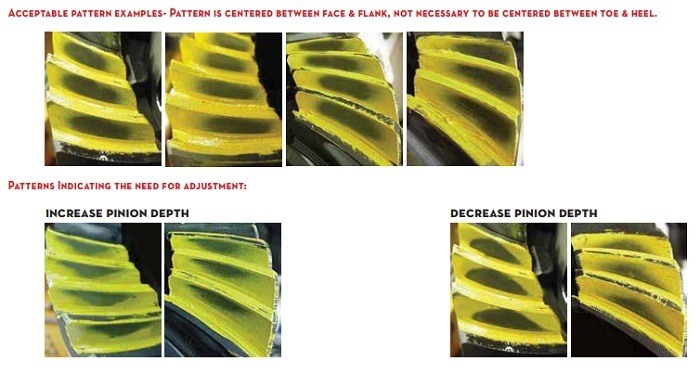

Hi: I have the front axle of my L3010D HST apart except for the diff. The bottom bevel gears both had damaged teeth with a lot of metal filings in the bottom of the housings. I have the two bevel gears, bearings, and axle seals ordered. The 42 tooth gears are in good shape. The service manual states to place "fuse" (I am assuming this means plastigage) in three places on the gear teeth and then to carefully rotate the gear to determine back lash/clearance and insert different thicknesses of shims behind the bearing to arrive at the proper clearance.

Here's my question: Is the plastigage placed on a gear tooth face, or in the valley between the teeth?

Thanks.

Here's my question: Is the plastigage placed on a gear tooth face, or in the valley between the teeth?

Thanks.