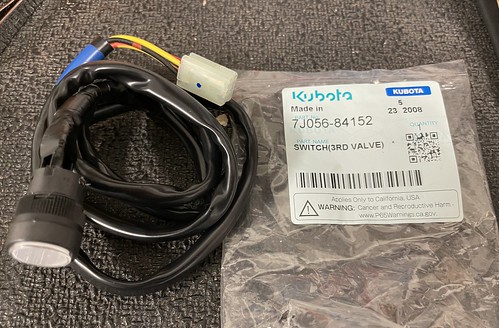

I've been reading this thread with interest as I've also got a problem that involves that same switch. And I would love to replace it with something better. It is used on the Kubota M59 TLB where it does the same thing: controls the relay that activates the 3rd Function valve. But mine is brokenI agree when this switch fails just moving to marine toggle

It is mounted next to the FEL control, which in turn is mounted on the plastic lever control assembly cover just to the right of the operator's seat. All of the PTO, 3pt, and HST controls stick up through slots in this plastic assembly cover. (photo attached).

The cover itself is part 040 in the diagram, and the shaded areas indicate slots where levers poke through. Only one lever #010 is shown, with its knob #030. However There are at least half a dozen levers and knobs.

The problem I have is I need to lift that plastic assembly cover to mount the switch we are talking about... and also need to lube the FEL wobble plate & control cables. But I cannot figure out how to lift that plastic assembly cover off of the various control levers. The knobs on top of the levers don't come off and are too big to fit through the slots. I'm perplexed.... just cannot figure how to get those knobs off so that the cover can be lifted.

I don't want to saw the assembly cover into pieces, it makes more sense to grind the knobs off of all the levers and then make new knobs, but there are a bunch: PTO, Range Shift, Throttle, HST controls...and so on. That's a lot of knobs to replace.

I'm missing something here. Any ideas?

rScotty