JosephGozo

Member

Equipment

Kubota B7001 + an ever growing list of attachments (restored / homemade) :(

Hi, It is a boring Sunday Evening for me so I thought I'd post a little bit about my coolant pump in the b7001.

Ever since I got the Kubota a decade ago I wished to find a way to cool it. Working the CAEB in hot Maltese summers (35'C) is no joke and even working a 4 foot tiller caused the engine to run hot and stall at times. The whistle was removed and it did have a snapped cylinder head bolt which suggested an overheating issue in the past.

Initially I installed a small brass pump (catering liquid transfer - Rover Pump) which was not designed to run hot liquids. it only had a regular oil seal that ran on a stainless shaft. It did well and lasted a couple of years until it ate the shaft.

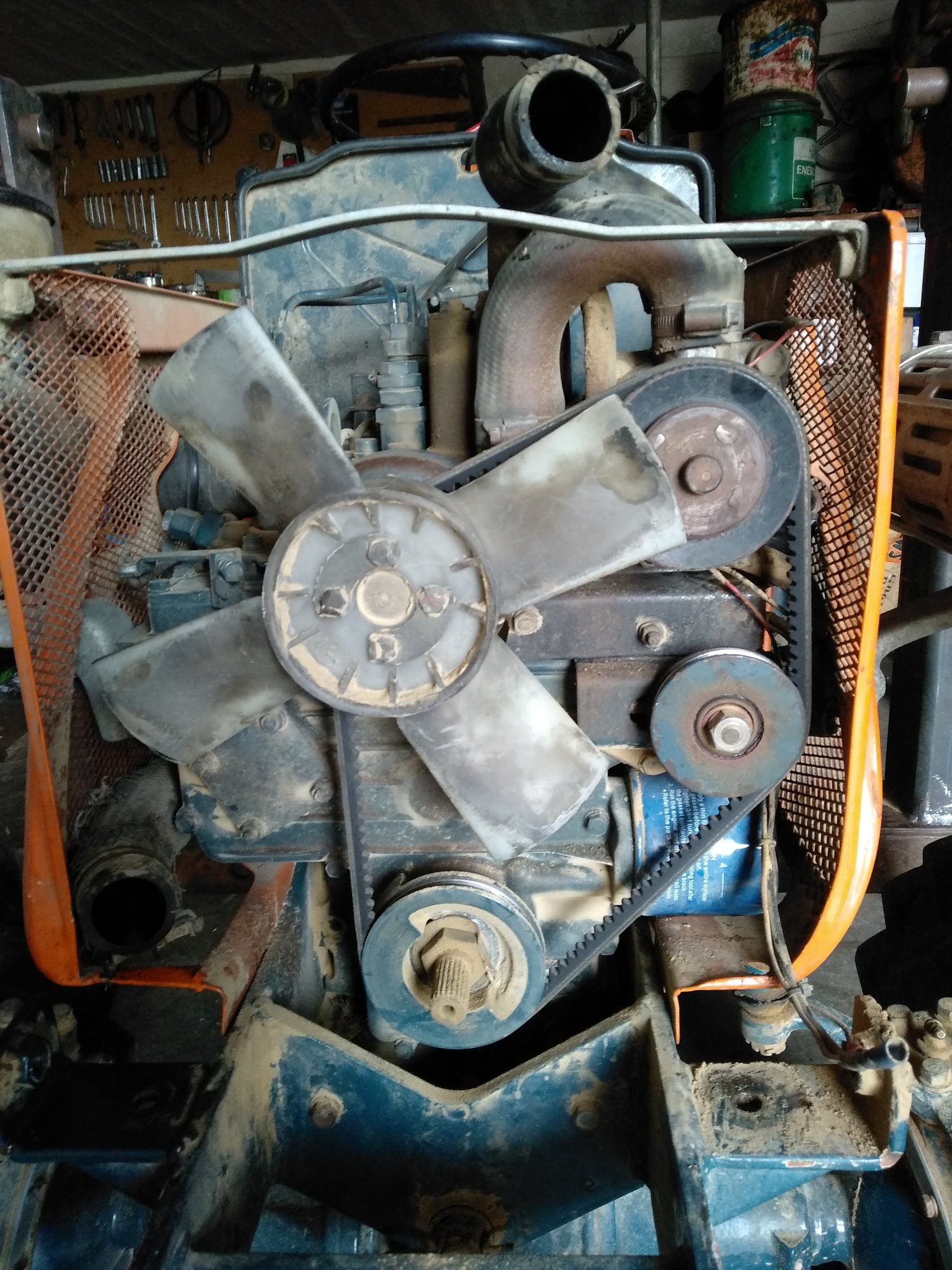

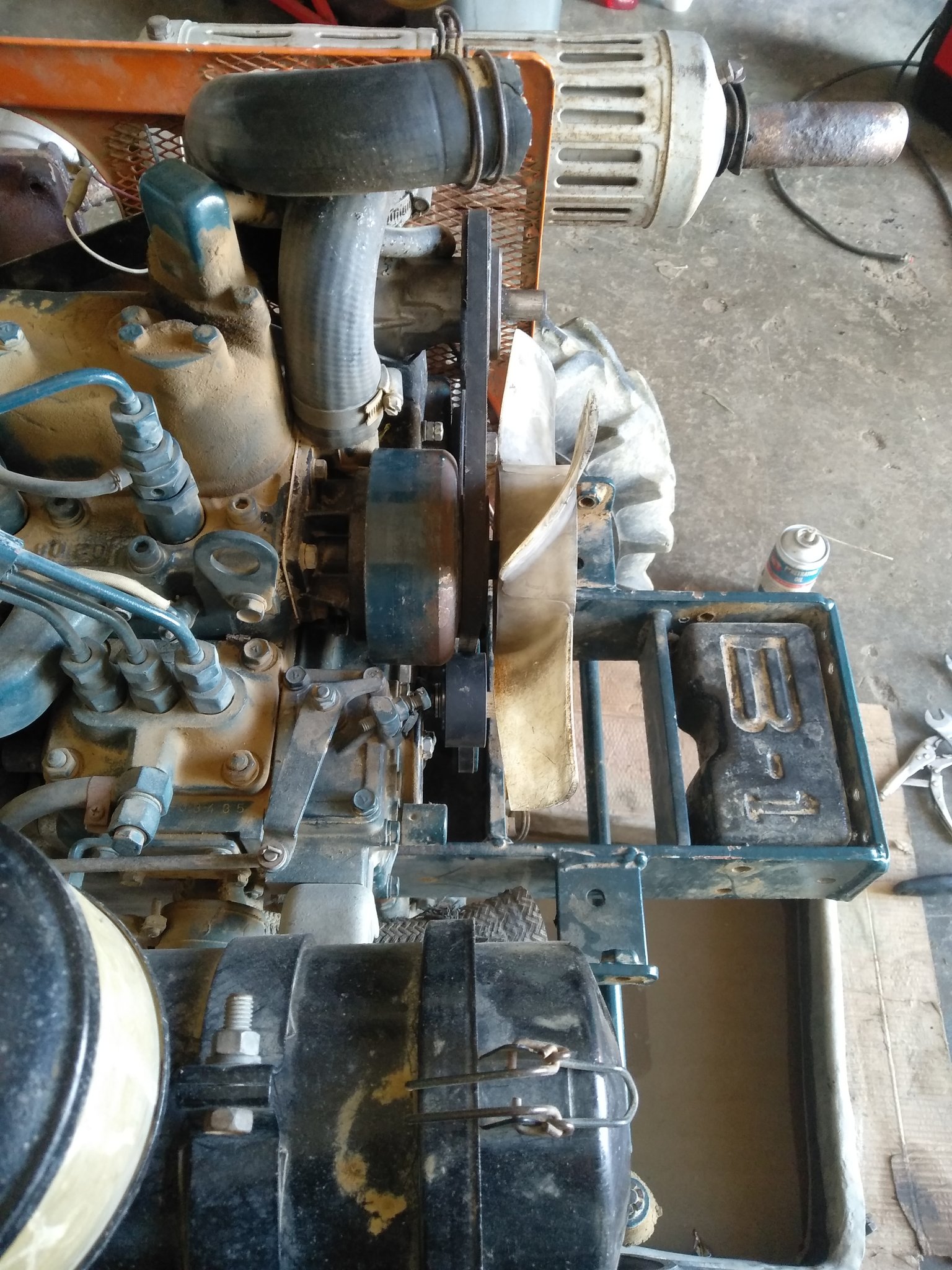

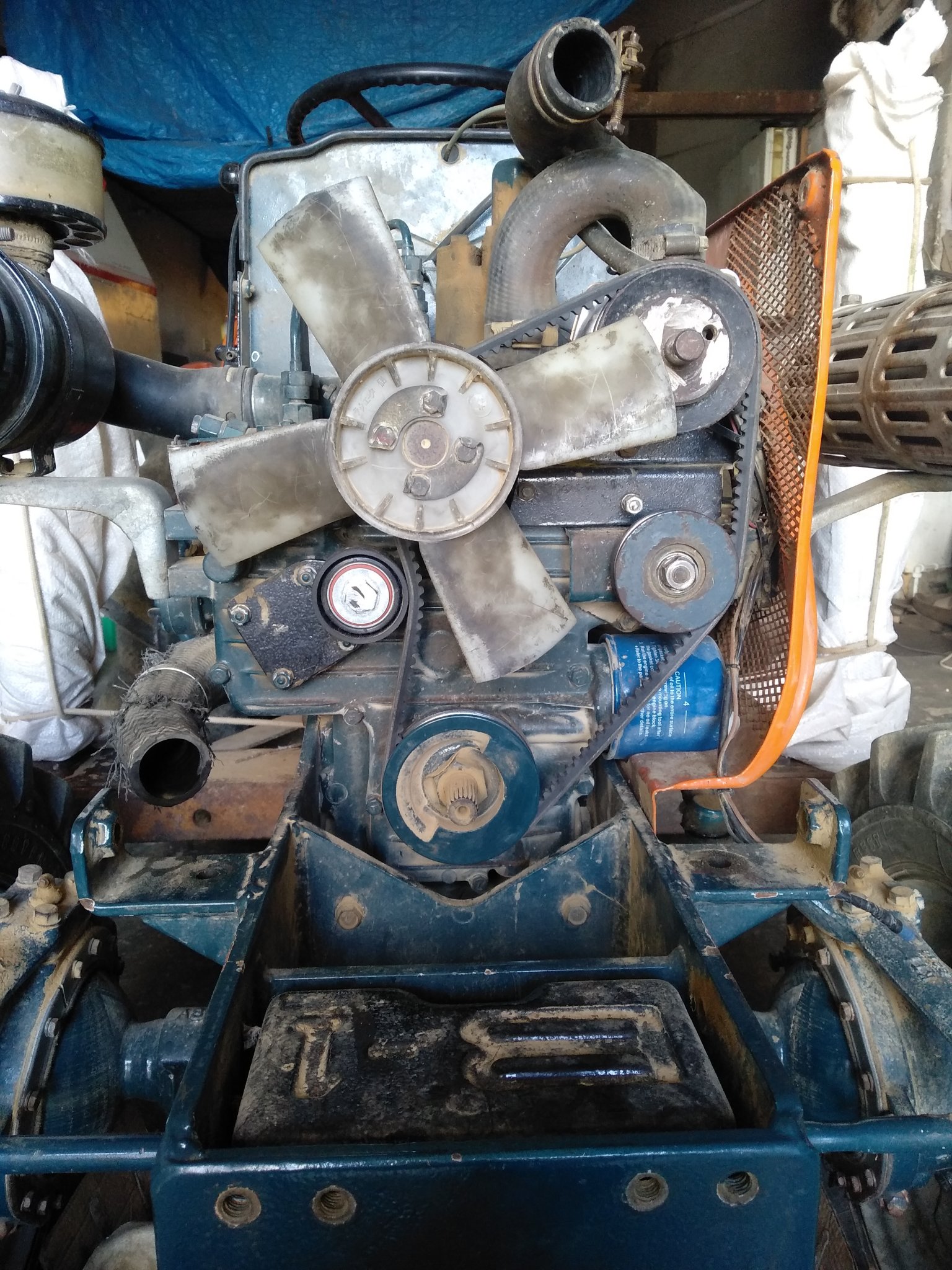

Then a friend of mine whose father had a stock of new old stock pumps found me a flanged pump (not sure about the make. I welded a 3/4" elbow with a couple of inches of tubing to direct its output to the top of the radiator. The pump is mounted on plate which shares the same mounts as the kubota belt tensioner. I did buy a bunch of 35mm inner diameter automotive hoses which included lots of bends and twists including a U bend.

The U bend was important to mate the pump to the cylinder head outlet to suck the coolant from the engine. the pump sits flush against the exhaust manifold since there is not much space. It also sits lower than the maximum coolant level in radiator in order to avoid air pockets and aiding suction. The pulley was installed the other way round to assist with alignment but I guess I will have to search for a better pulley and get it machined to cater for the offset and fix the alignment which is off by a couple of mm. In the absence of a thermostat I also tried to install a big pulley in order to lower the pump speed/flow rate

The temperature sender is mounted on the back of the pump. Not the ideal place but i am a bit scared of drilling in the head and tapping in a sender. Under heavy load (tiller/Baler work) it managed to keep the temperatures steady between 80'C and 95'C on the gauge that i installed (a Suzuki gauge with matching sender) I could actually work for hours on end and temperature stays at the same level.

Not long ago I noticed that it was struggling and I ruined the pump by over tightening the belt fearing the fan was slipping because of minimal contact by belt on the fan pulley. That friend gave me another such pump. It turned out to be a blocked radiator because scales from the engine got lodged in the tubes of the radiator. I decided to recore it locally (half the price of a new one.) since the fins were also flaking off. Only disappointment was that the guy shortened the core by half an inch making the front screen barely clip in place Radiator was topped up with distilled water and ran for a few hours before draining and refilling with Red coolant. It is supposed to protect the internals. I had a little problem with the dynamo housing (holes crumbling all over the place). Had it welded up twice but then replaced but it is quite pricey.

Radiator was topped up with distilled water and ran for a few hours before draining and refilling with Red coolant. It is supposed to protect the internals. I had a little problem with the dynamo housing (holes crumbling all over the place). Had it welded up twice but then replaced but it is quite pricey.

So while the radiator was away being refurbished I thought about installing a tensioner (new for a BMW car) between the fan and the crank pulleys to help add more grip around the fan pulley. I used the existing 4 studs on the front of the engine to tighten up 3mm plate with an M10 nut welded on the outer side. I had a spacer/mount machined to take the 6203 bearing on which the tensioner spins.

Ever since the recore it runs great and cooling down after a workout is instant. I did till two plots for a neighbour (about 3 hours on 2nd low and 1st speed pto). The temperature needle was always hovering around the 80/90'C. i guess the coolant in the engine was a bit hotter but did well. Usually I had to break down the job in 3 or 4 goes to let it cool down.

Joe

Ever since I got the Kubota a decade ago I wished to find a way to cool it. Working the CAEB in hot Maltese summers (35'C) is no joke and even working a 4 foot tiller caused the engine to run hot and stall at times. The whistle was removed and it did have a snapped cylinder head bolt which suggested an overheating issue in the past.

Initially I installed a small brass pump (catering liquid transfer - Rover Pump) which was not designed to run hot liquids. it only had a regular oil seal that ran on a stainless shaft. It did well and lasted a couple of years until it ate the shaft.

Then a friend of mine whose father had a stock of new old stock pumps found me a flanged pump (not sure about the make. I welded a 3/4" elbow with a couple of inches of tubing to direct its output to the top of the radiator. The pump is mounted on plate which shares the same mounts as the kubota belt tensioner. I did buy a bunch of 35mm inner diameter automotive hoses which included lots of bends and twists including a U bend.

The U bend was important to mate the pump to the cylinder head outlet to suck the coolant from the engine. the pump sits flush against the exhaust manifold since there is not much space. It also sits lower than the maximum coolant level in radiator in order to avoid air pockets and aiding suction. The pulley was installed the other way round to assist with alignment but I guess I will have to search for a better pulley and get it machined to cater for the offset and fix the alignment which is off by a couple of mm. In the absence of a thermostat I also tried to install a big pulley in order to lower the pump speed/flow rate

The temperature sender is mounted on the back of the pump. Not the ideal place but i am a bit scared of drilling in the head and tapping in a sender. Under heavy load (tiller/Baler work) it managed to keep the temperatures steady between 80'C and 95'C on the gauge that i installed (a Suzuki gauge with matching sender) I could actually work for hours on end and temperature stays at the same level.

Not long ago I noticed that it was struggling and I ruined the pump by over tightening the belt fearing the fan was slipping because of minimal contact by belt on the fan pulley. That friend gave me another such pump. It turned out to be a blocked radiator because scales from the engine got lodged in the tubes of the radiator. I decided to recore it locally (half the price of a new one.) since the fins were also flaking off. Only disappointment was that the guy shortened the core by half an inch making the front screen barely clip in place

So while the radiator was away being refurbished I thought about installing a tensioner (new for a BMW car) between the fan and the crank pulleys to help add more grip around the fan pulley. I used the existing 4 studs on the front of the engine to tighten up 3mm plate with an M10 nut welded on the outer side. I had a spacer/mount machined to take the 6203 bearing on which the tensioner spins.

Ever since the recore it runs great and cooling down after a workout is instant. I did till two plots for a neighbour (about 3 hours on 2nd low and 1st speed pto). The temperature needle was always hovering around the 80/90'C. i guess the coolant in the engine was a bit hotter but did well. Usually I had to break down the job in 3 or 4 goes to let it cool down.

Joe