The gasket repair seems to have worked, fingers crossed.

I have another question - I'm slowly working through all the issues on this tractor

- I'm slowly working through all the issues on this tractor

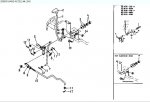

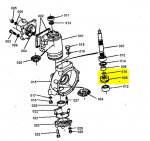

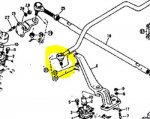

It looks like the front end was removed at some stage, maybe to fix a water pump. There is this extra spring attached to the speed controller and whats looks like an extra home made welded rod to to stop the machine. I assumed the spring may have been replacing a governor spring which can be damaged if not removed (and judging by the careless nature some of the"characters" who have worked on this machine put things back together that would not be a surprise) and the new stop rod was a replacement for something that got broken. Looking at the operators manual my tractor has a pull straight back to stop type lever like the L355, not a pull up to stop lever. This may be because it has an after market cab. If someone could post what it should look like at the speed control plate, I can reverse engineer from there.

I have another question

It looks like the front end was removed at some stage, maybe to fix a water pump. There is this extra spring attached to the speed controller and whats looks like an extra home made welded rod to to stop the machine. I assumed the spring may have been replacing a governor spring which can be damaged if not removed (and judging by the careless nature some of the"characters" who have worked on this machine put things back together that would not be a surprise) and the new stop rod was a replacement for something that got broken. Looking at the operators manual my tractor has a pull straight back to stop type lever like the L355, not a pull up to stop lever. This may be because it has an after market cab. If someone could post what it should look like at the speed control plate, I can reverse engineer from there.