I recently bought a L245DT circa 1977. The seller told me the 3pt hitch had worked until recently but the control lever “went bad”. It was flopping around uselessly but everything else was good. I drove it around, used the FEL and drove it a mile back to my house. It was there that I discovered that the 3pt speed control (below the seat) was locked tight. I loosened it and the 3 pt hitch worked! I tightened the lock nuts on the lever control to get some friction and hold the lever in place. Not sure if it means anything but I found the hydraulic fluid very high, I drained at least a gallon out before it slowed down at the check hole. Everything worked for a few days until I put my brush mower on the hitch and dropped it down (too hard perhaps) and then nothing. The 3pt hitch wouldn’t pick up the mower no matter what I did.

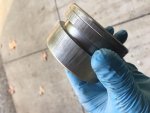

Finally I took off the seat, uncracked the eight (or so) nuts and bolts holding the top of the rear transaxle down and managed to lift it clear. Under the top of the case the rod (the lever spool drive according to parts list) that connects the lever control to the control mechanism (attached to the left 3pt arm) on the other side of the case was missing. I found it in the bottom of case under the gears and all that oil. I put it back in place, replaced the oil and screen, reassembled everything and it all now works. But here’s the question… why did it fall off in the first place? Did the 3pt arms extend too far down when I dropped the implement? Is the control gizmo attached to the 3pt arm, out of adjustment? Is the linkage attaching the main valve control to the spool drive rod (the part that fell off), out of adjustment? Should I be tightening the nuts on the 3pt lever to get friction or should there be a detent in the system? I have a shop manual that under-describes everything and is not much help. I’d appreciate any advice.

Finally I took off the seat, uncracked the eight (or so) nuts and bolts holding the top of the rear transaxle down and managed to lift it clear. Under the top of the case the rod (the lever spool drive according to parts list) that connects the lever control to the control mechanism (attached to the left 3pt arm) on the other side of the case was missing. I found it in the bottom of case under the gears and all that oil. I put it back in place, replaced the oil and screen, reassembled everything and it all now works. But here’s the question… why did it fall off in the first place? Did the 3pt arms extend too far down when I dropped the implement? Is the control gizmo attached to the 3pt arm, out of adjustment? Is the linkage attaching the main valve control to the spool drive rod (the part that fell off), out of adjustment? Should I be tightening the nuts on the 3pt lever to get friction or should there be a detent in the system? I have a shop manual that under-describes everything and is not much help. I’d appreciate any advice.