Lil Foot

Well-known member

Lifetime Member

Equipment

1979 B7100DT Gear, Nissan Hanix N150-2 Excavator

The forward-off-reverse selector switch on my engine lathe died. (housing broke up)

After a lengthy search, it became obvious the same switch is no longer available, but the switch I found was supposed to be a direct replacement, even has the same number, (HZ5B-10) and was touted as being a direct replacement for import metal lathes. However, I am unsure as to how to wire it, and would appreciate any help you folks good offer. Bear with me for the long post.

1st pic shows new and old switch. (old with zip ties)

2nd pic shows a red w/cream colored jumper from the original switch wiring.

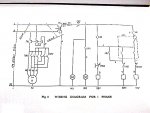

3rd & 4th are the wiring diagram & parts list from lathe manual

Motor is single phase 220V.

After a lengthy search, it became obvious the same switch is no longer available, but the switch I found was supposed to be a direct replacement, even has the same number, (HZ5B-10) and was touted as being a direct replacement for import metal lathes. However, I am unsure as to how to wire it, and would appreciate any help you folks good offer. Bear with me for the long post.

1st pic shows new and old switch. (old with zip ties)

2nd pic shows a red w/cream colored jumper from the original switch wiring.

3rd & 4th are the wiring diagram & parts list from lathe manual

Motor is single phase 220V.

Attachments

-

114.8 KB Views: 320

-

147.1 KB Views: 339

-

99.6 KB Views: 723

-

60.5 KB Views: 374

Last edited: